| Posted: Aug 22, 2006 | |

Non-toxic nanolithography using pure water |

|

| (Nanowerk Spotlight) Conventionally, the fabrication of thin film nanostructures is primarily done by using selective etching or templating growth on a prepatterned resist and then performing lift-off. The solvents used in developing resist are typically toxic and add to the cost of lithographic processing. Recently, many environmentally friendly lithographic processes have been designed using either a water-based solution or supercritical carbon dioxide to develop the resist. A novel pure water developable spin-coatable lanthanum strontium manganese oxide (LSMO) resist has been developed by scientists in Taiwan. The use of pure water instead of organic or alkaline solvents would undoubtedly be not only environmentally desirable but also could greatly simplify the imaging process. | |

| During semiconductor or thin film production, a conventional resist serves as passive masking function which is removed after the circuit is generated. The solvents used in developing resist are typically volatile and toxic, contributing to health hazards and environmental pollution. | |

| Dr. Wei-Fang Su, professor in the Department of Materials Science and Engineering at Taiwan National University, explained a novel water-based process to Nanowerk: "We have developed a direct writing resist from the LSMO using its precursor solution. This solution is functioned as a resist via an auto ignition mechanism during electron beam exposure, and the patterned LSMO film can be developed using nontoxic and environmental friendly pure water." | |

|

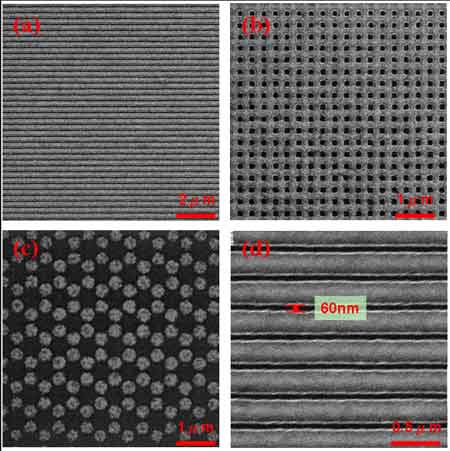

(a) SEM image of patterned lines, 250 nm wide, of spin-coatable LSMO resist. (b) SEM image of a large array of 125 nm lines. (c) SEM image of a periodic pattern with honeycomb style. The diameter of the light-colored circle in the center is 400 nm. (d) SEM image of a patterned line: the designed pattern is of straight lines with a width of 240 nm and an interval of 60 nm. (Reprinted with permission from IOP Publishing Ltd.) |

| Su and her colleagues report their findings in a recent paper, titled "Nanolithography made from water-based spin-coatable LSMO resist", published in the August 14, 2006 online edition of Nanotechnology. | |

| Either positive or negative patterns can be easily produced from the water-based magnetic resist material by varying the electron doses. The resist material consists of the oxide precursors of La, Sr, Mn, and a phase formation promoter. The phase formation promoter is polymer that assists the formation of the perovskite crystalline structure of lanthanum strontium manganese oxide. | |

| "Pure water is used to develop the resist" says Su. "Various nanoscale patterns can be formed from the material using an electron beam. An external magnetic field on the spin-coatable LSMO resist samples shows colossal and negative magnetoresistance effects (CMR). The material also exhibits high refractive index (∼2.38). These properties are useful for the direct fabrication of waveguide, photonic crystal, optoelectronic devices, optomagnetic devices and spintronics." | |

| Continuing her research on this material, Su says that the near term goal is to study the interactions between the light and magnetic waves from patterned arrays fabricated from this material. By modulating the magnetic wave or light wave the researchers hope to fabricate novel devices. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.