Showing Spotlights 9 - 16 of 29 in category All (newest first):

The desire to identify materials and their properties to understand complex systems and better engineer their functions has been driving scanning probe microscopies since their inception. Both atomic force microscopy (AFM) and Raman spectroscopy are techniques used to gather information about the surface properties and chemical information of a sample. There are many reasons to combine these two technologies, and this application note discusses both the complementary information gained from the techniques and how a researcher having access to a combined system can benefit from the additional information available.

The desire to identify materials and their properties to understand complex systems and better engineer their functions has been driving scanning probe microscopies since their inception. Both atomic force microscopy (AFM) and Raman spectroscopy are techniques used to gather information about the surface properties and chemical information of a sample. There are many reasons to combine these two technologies, and this application note discusses both the complementary information gained from the techniques and how a researcher having access to a combined system can benefit from the additional information available.

Mar 6th, 2014

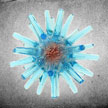

More serious than the common cold, influenza viral infection has been responsible for major epidemics and pandemic respiratory disease in communities around the world. These epidemics come with substantial morbidity and mortality, accounting for 250,000 to 500,000 worldwide deaths each year and are particularly dangerous for vulnerable and elderly populations with statistics showing that 90% of those who succumb to the severe illness are 65 years and older. The flu is also associated with high health care costs. In the U.S., more than $80 billion dollars is spent annually as a result of influenza epidemics.

More serious than the common cold, influenza viral infection has been responsible for major epidemics and pandemic respiratory disease in communities around the world. These epidemics come with substantial morbidity and mortality, accounting for 250,000 to 500,000 worldwide deaths each year and are particularly dangerous for vulnerable and elderly populations with statistics showing that 90% of those who succumb to the severe illness are 65 years and older. The flu is also associated with high health care costs. In the U.S., more than $80 billion dollars is spent annually as a result of influenza epidemics.

Mar 3rd, 2014

Surface metrology and characterization is ever more critical for overall product performance in wide ranging applications across the semi-conductor, LED, data storage, medical and automotive industries. 3D optical microscopes are among the fastest and most accurate imaging systems on the market today, and are employed in these industries for rapid and precise process monitoring, product development, and research. However, there are instances where they have performance limitations and the benefits of scanning probe/atomic force microscopy provide a clear advantage.

Surface metrology and characterization is ever more critical for overall product performance in wide ranging applications across the semi-conductor, LED, data storage, medical and automotive industries. 3D optical microscopes are among the fastest and most accurate imaging systems on the market today, and are employed in these industries for rapid and precise process monitoring, product development, and research. However, there are instances where they have performance limitations and the benefits of scanning probe/atomic force microscopy provide a clear advantage.

Feb 6th, 2014

Ingenuity Lab in Edmonton, Alberta are taking cues from nature, as they focus on nanotechnology gains in the area of biomining. Using microorganisms and biomolecules, the group is making significant advances in the recovery of rare earth and precious metals from industrial processes and the environment thanks to superior molecular recognition techniques. The researchers at Alberta's first nanotechnology accelerator laboratory are looking to take advantage of inorganic binding peptides for mining valuable and rare earth elements/metals that exist in nature or synthetic materials.

Ingenuity Lab in Edmonton, Alberta are taking cues from nature, as they focus on nanotechnology gains in the area of biomining. Using microorganisms and biomolecules, the group is making significant advances in the recovery of rare earth and precious metals from industrial processes and the environment thanks to superior molecular recognition techniques. The researchers at Alberta's first nanotechnology accelerator laboratory are looking to take advantage of inorganic binding peptides for mining valuable and rare earth elements/metals that exist in nature or synthetic materials.

Feb 3rd, 2014

Measuring and mapping mechanical properties of live cells is of high importance in today's biological research. raditionally, force spectroscopy and force volume are the most commonly used modes to quantitatively measure mechanical forces at the nanometer scale. Unfortunately, both techniques have suffered from slow acquisition speed and a lack of automated tools to analyze the hundreds to thousands of curves required for good statistics. This application note reviews recent progress in mapping the properties of soft samples such as cells and gels with force volume and PeakForce QNM and the use of the newest NanoScope and NanoScope Analysis features to collect and analyze the data from these techniques.

Measuring and mapping mechanical properties of live cells is of high importance in today's biological research. raditionally, force spectroscopy and force volume are the most commonly used modes to quantitatively measure mechanical forces at the nanometer scale. Unfortunately, both techniques have suffered from slow acquisition speed and a lack of automated tools to analyze the hundreds to thousands of curves required for good statistics. This application note reviews recent progress in mapping the properties of soft samples such as cells and gels with force volume and PeakForce QNM and the use of the newest NanoScope and NanoScope Analysis features to collect and analyze the data from these techniques.

Dec 30th, 2013

Recent developments in nanotechnology have enabled significant improvement in the field of anti-counterfeiting measures. One company for instance is working on fluorescent nanostructures to improve banknote security; another one has developed DNA tags for deposition on nanoelectronics wafers and computer chips to ensure the integrity and security of processed wafers. DNA-based protection technologies are especially suitable for anti-counterfeiting measures.The DNA molecules are added a products raw material during the production process. Only 1 ppm (one part per million) is required to uniquely mark the material The DNA molecular structure can then be read as a mathematical code based on the four DNA molecules. So a DNA code, in contrast to the binary code used in IT security, is a combination of the letters A, C, G and T. A 10-digit code could look like this: C-G-A-C-T-T-G-A-C-A.

Recent developments in nanotechnology have enabled significant improvement in the field of anti-counterfeiting measures. One company for instance is working on fluorescent nanostructures to improve banknote security; another one has developed DNA tags for deposition on nanoelectronics wafers and computer chips to ensure the integrity and security of processed wafers. DNA-based protection technologies are especially suitable for anti-counterfeiting measures.The DNA molecules are added a products raw material during the production process. Only 1 ppm (one part per million) is required to uniquely mark the material The DNA molecular structure can then be read as a mathematical code based on the four DNA molecules. So a DNA code, in contrast to the binary code used in IT security, is a combination of the letters A, C, G and T. A 10-digit code could look like this: C-G-A-C-T-T-G-A-C-A.

Nov 6th, 2012

Bio-conjugated nanoparticles are important analytical tools with emerging biological and medical applications. Especially gold nanoparticles are of increasing interest for nanobiotechnology research and applications because of their high acceptance level in living systems and the fact that they are fairly easily conjugated with functional molecules. Ultrashort pulsed laser ablation represents a powerful tool for the generation of pure gold nanoparticles avoiding chemical precursors, reducing agents, and stabilizing ligands. The bare surface of the charged nanoparticles makes them highly available for functionalization and as a result especially interesting for biomedical applications. Starting today, such conjugates are available commercially for the first time.

Bio-conjugated nanoparticles are important analytical tools with emerging biological and medical applications. Especially gold nanoparticles are of increasing interest for nanobiotechnology research and applications because of their high acceptance level in living systems and the fact that they are fairly easily conjugated with functional molecules. Ultrashort pulsed laser ablation represents a powerful tool for the generation of pure gold nanoparticles avoiding chemical precursors, reducing agents, and stabilizing ligands. The bare surface of the charged nanoparticles makes them highly available for functionalization and as a result especially interesting for biomedical applications. Starting today, such conjugates are available commercially for the first time.

Sep 15th, 2011

Nanoindentation is derived from the classical hardness test but is carried out on a much smaller scale. It can be used to determine the hardness of thin layers as well as material properties such as elasticity, stiffness, plasticity, and tensile strength, or fracture toughness of small objects and microsystems in fields such as biotechnology. These measurements involve applying a small force to a sample using a sharp probe and measuring the resultant penetration depth. The measured value is used to calculate the contact area and hence the particular property of the sample material. Both the method of force application and the geometry of the indentation tip can be adjusted to suit the particular application.

Nanoindentation is derived from the classical hardness test but is carried out on a much smaller scale. It can be used to determine the hardness of thin layers as well as material properties such as elasticity, stiffness, plasticity, and tensile strength, or fracture toughness of small objects and microsystems in fields such as biotechnology. These measurements involve applying a small force to a sample using a sharp probe and measuring the resultant penetration depth. The measured value is used to calculate the contact area and hence the particular property of the sample material. Both the method of force application and the geometry of the indentation tip can be adjusted to suit the particular application.

Jun 29th, 2011

The desire to identify materials and their properties to understand complex systems and better engineer their functions has been driving scanning probe microscopies since their inception. Both atomic force microscopy (AFM) and Raman spectroscopy are techniques used to gather information about the surface properties and chemical information of a sample. There are many reasons to combine these two technologies, and this application note discusses both the complementary information gained from the techniques and how a researcher having access to a combined system can benefit from the additional information available.

The desire to identify materials and their properties to understand complex systems and better engineer their functions has been driving scanning probe microscopies since their inception. Both atomic force microscopy (AFM) and Raman spectroscopy are techniques used to gather information about the surface properties and chemical information of a sample. There are many reasons to combine these two technologies, and this application note discusses both the complementary information gained from the techniques and how a researcher having access to a combined system can benefit from the additional information available.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed