| Posted: Sep 26, 2007 | |

Bridges in nanotechnology |

|

| (Nanowerk Spotlight) Bridges are exciting to cross, incredible works of engineering and they have made it possible for us to travel more easily, quickly and safely. The U.S. Congress even approved $400 million to build a bridge to nowhere. While bridges have been, and still are, essential components in every society’s infrastructure, the bridge concept is becoming interesting to nanotechnology researchers as well. Nanomaterial air bridges enable nanoscale structures to be suspended as a two-point beam, creating a nanomechanical element that is isolated from a variety of substrate effects, including adhesion, temperature, conductivity, and parasitic capacitance. The bridge-like suspension makes nanoscale structures accessible along their length, which is beneficial for examining ehmt but also for device construction. It also allows nearfield probing, manipulation, and actuation of these suspended nanostructures. Scientists at the University of Louisville have found a way to build nanomaterial air bridges simply and conveniently. | |

| "Typically, air bridges are built using two different processes" Dr. Robert W. Cohn explains to Nanowerk. "Scientists disperse nanomaterials in solvents, followed by mapping, lithographic patterning and undercutting, which is a labor intensive process and requires that fabrication is accomplished in a cleanroom. Another method is to grow nanomaterials in high temperature reactors, but this requires scientists to have an appropriate growth recipe for the particular material they are using." | |

| In contrast, Cohn and his team came up with a simple two-step method to form suspended and oriented nanomaterials – either polymer composites or the nanomaterial loaded in the polymer." | |

| Cohn, Professor and Director of the ElectroOptics Research Institute & Nanotechnology Center at the University of Louisville in Kentucky, reported in a recent paper in ACS NANO how they form nanomaterial air bridges by connecting carbon nanotubes, inorganic nanowires and graphene sheets between two anchor points ("Oriented Nanomaterial Air Bridges Formed from Suspended Polymer Composite Nanofibers"). | |

| In previous research ("Forming Highly Ordered Arrays of Functionalized Polymer Nanowires by Dewetting on Micropillars" and "Direct Drawing of Suspended Filamentary Micro- and Nanostructures from Liquid Polymers"), the Louisville scientists and others have shown that suspended nanofibers (as small as 50 nm in diameter) are formed by hand brushing solutions of polymer in volatile solvent onto micro-sized corrugated surfaces. | |

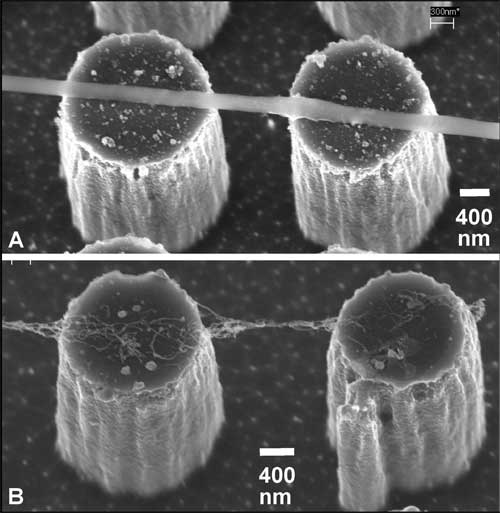

| In this recent research, Cohn and his team demonstrate that this process can be extended to suspend a variety of nanomaterials by forming fibers from solutions of nanomaterials and polymers. The suspended nanomaterial-composite fiber is thermally decomposed to leave an air bridge of the nanomaterial. Composition analysis suggests the process removes nearly all of the residue. Another advantage, they say, is that by brushing on the solution, the fibers can be well-oriented in the direction of brushing, and can be suspended from either the top of the sides of the support pillars. | |

|

|

| Suspension of multi-walled carbon nanotubes (MWCNTs) by sacrificial decomposition of a suspended PMMA (poly(methyl methacrylate))–MWCNT fiber. A) An air bridge of the composite fiber and B) the resulting MWCNT air bridge following thermal decomposition of the PMMA in the composite fiber. For electrospinning, the solution was pumped at 0.6 mL/h to a needle 5 cm long x 0.7 mm inner diameter, with 13 kV applied between the needle and pillar array at a separation of 5 cm. The sidewall roughness and particulates on the pillars are due to the conditions used during the plasma etching of this (n-type, 4Ω-cm) silicon substrate. (Reprinted with permission from American Chemical Society) | |

| The scientists applied a thin bead of solution from a pipette to the edge of an applicator, and manually brushed the solution across the surface. | |

| Cohn describes how "thick liquid bridges initially form between adjacent sidewalls and then thin due to capillary forces, finally reaching a stable diameter after enough of the solvent evaporates." | |

| Using electron-spun carbon nanotubes, the scientists demonstrate that this vital decomposition step can also be applied to nanofibers formed by processes other than the brush-on method. | |

| Cohn notes that, in developing control of the process, two important conditions must exist: "1) The polymer fibers and the nanomaterials in the polymer must both span the supports; 2) The polymer must also be heated rapidly enough so that it decomposes before it begins to fall apart due to reflow." | |

| Although no comprehensive yield studies have been conducted yet, this current research offers insight into the reliability and controllability of making air bridges based on casual observations. | |

| "Using SEM images of 30 nanotube brush-on experiments, we observed a local area of as many as 30 nanotube air bridges without a single missing bridge" says Cohn. "However, for much larger areas consisting of as many as 300 pillars, we found as many as 75% of the bridges missing. We attributed this to the smaller size of the fibers, which had diameters between 50 and 150 nm (as compared to diameters around 200–400 nm for most typical samples). | |

| Cohn points out that, although they have far less data available for experiments using gallium arsenide phosphide (GaAsP) nanowires and graphene sheets, the early results are promising. "Even with low concentrations we frequently found three or four consecutive bridges for the GaAsP nanowires formed from a single fiber, and two consecutive bridges for graphene" he says. | |

| The brush-on process, followed by decomposition, provides a new tool for creating test structures for the evaluation and characterization of suspended nanomaterials. Applications for this research are varied. | |

| "Possible applications include NEMS actuators and sensors and determinations of mechanical, electrical and thermal/phonic/Raman properties of the suspended materials," says Cohn. "The composite fibers would enable nanoscale studies of adhesion of the nanomaterials to the polymer matrix, which is key to the understanding of the strength, toughness and crack resistance of composites materials in general." | |

| Cohn says this research is already showing promise for future applications. "I can see the individual results suggesting entirely new processing flows to fabricate unique nano- and micro-devices from the bottom up," he says. According to Cohn, the materials, structures and devices appear to have very surprising and useful properties, which he is currently measuring and attempting to exploit. "It appears that the properties are especially well-matched as probes for performing fundamental biophysical measurements with possible future medical diagnostic applications." | |

| By Cathy Garber, Copyright Nanowerk LLC | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|