| Posted: Feb 21, 2006 | |

New, low-cost method to synthesize high-purity and large-scale inorganic fullerene-like nanoparticles |

|

| (Nanowerk News) As a lubricant, some inorganic fullerene-like nanomaterials (IFs) have shown to be more effective than oil-based liquids with solid lubricant additives. This means less wear and tear on machinery than users get with more traditional lubricants. Many IFs are currently being synthesized by different methods as pure materials. It has remained a challenge, though, to develop more economical methods to produce these IFs in sufficient quantities at acceptable prices for industrial use. | |

| Researchers at Jilin University in the People's Republic of China explained to Nanowerk how they developed a simple, large-scale and low-cost route to synthesize IFs. | |

| |

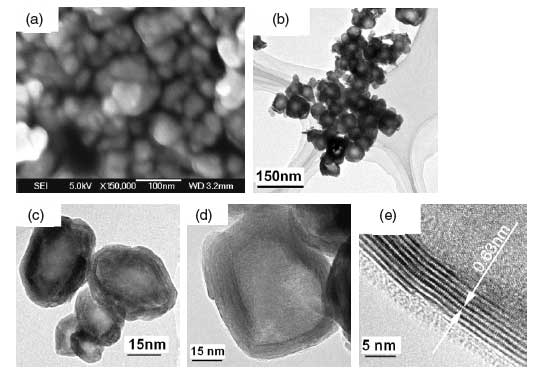

| High-magnification FESEM image (a) of as-prepared WO3 nanoparticles. TEM (b) and typical HRTEM ((c)–(e)) images of as-synthesized IF-WS2 nanoparticles annealed at 620°C for 30 min. These IF-WS2 nanoparticles are almost sub-globular and the average size is about 50 nm (a); all the nanoparticles possess closed hollow structure ((c) and (d)); the interlayer spacing is about 0.63 nm (e).(Source: Jilin University) | |

| Following the discovery of carbon fullerenes and nanotubes, the first closed-cage non-carbon fullerene-like nanoparticles and nanotubes of WS2 (tungsten disulphide) were reported by Tenne et. al. in 1992. These nanomaterials with new structures were generally given the name of inorganic fullerene-like materials. | |

| Among IFs, transition metal sulfides (IF-MS2) are of greater interest to researchers due to their physical and chemical properties. Besides being superior solid lubricants, IF-MS2 nanomaterials have shown promising applications as electron devices, catalysts, electrochemical hydrogen storage bodies, super shock absorbers, photosensitive films and ultrastrong tips for scanning microscopy. Because of their interesting properties and promising applications, intense interest has been shown in developing new IFs and ways of synthesizing them. | |

| Professor Haibin Yang who, together with Dr. Shikai Liu, was the main author of the below-mentioned report, sees a bright commercial future for IF-MS2 nanoparticles such as IF-WS2, if the fabrication process is made more economical. | |

| As Professor Yang explained to Nanowerk: "We found a simple route for the synthesis of IF-WS2 nanoparticles by the reaction of sulfur (S) powder and tungsten trioxide (WO3) nanoparticles in a hydrogen atmosphere at a heating temperature of 500-650°C. This reaction process is easy to control. It allows us to produce IF-WS2 in high purity and large scale at low cost. These features are indispensable for future industrial applications." | |

| "In particular" Dr. Liu added, "we discovered that the outputs could be easily increased with almost no decrease in quality simply by changing the amount of composite powders, WO3 and S, and the content of hydrogen." | |

| The three main parts of the relatively uncomplicated process are synthesis of the WO3 nanoparticles, preparation of the composite powders and synthesis of IF-WS2 in a hydrogen atmosphere. The method also does not require an expensive and timeconsuming purification process, further adding to the production efficiencies. The resulting IF-WS2 nanoparticles are of a closed hollow cage structure with an average size of about 50 nm. | |

| A report on these findings, titled "Synthesis of inorganic fullerene-like WS2 nanoparticles and their lubricating performance" appeared in the Feb. 16, 2006 online edition of Nanotechnology. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.