| Posted: Aug 29, 2013 | |

Nanotechnology T-Shirt to replace batteries? Towards wearable energy storage |

|

| (Nanowerk Spotlight) If current research is an indicator, wearable electronics will go far beyond just very small electronic devices or wearable, flexible computers. Not only will these devices be embedded in textile substrates but an electronics device or system could ultimately become the fabric itself. Electronic textiles (e-textiles) will allow the design and production of a new generation of garments with distributed sensors and electronic functions. Such e-textiles will have the revolutionary ability to sense, act, store, emit, and move – think biomedical monitoring functions or new man-machine interfaces – while ideally leveraging an existing low-cost textile manufacturing infrastructure (read more: "Nanotechnology e-textiles for biomonitoring and wearable electronics"). | |

| All these wearable and potentially textile-embedded electronic gadgets will require power; and it wouldn't make sense to have to plug your sleek flexible sleeve display into a bulky lithium-ion battery brick. Researchers are therefore pushing the development of wearable energy storage. Especially supercapacitors with a cable-type architecture could lead to flexible energy storage devices that can remove traditional restriction and achieve a subversive technology that could open up a path for design innovation. | |

| Researchers have now demonstrated that flexible cotton threads can be used as a platform to fabricate a cable-type supercapacitor. An international team from the Center for Nanoscale Characterization & Devices (CNCD) at the Wuhan National Laboratory for Optoelectronics and the International Center for Materials Nanoarchitectonics (MANA) at National Institute for Materials Science (NIMS) has reported in Advanced Materials a novel high-performance cable-type supercapacitor based on three-dimensional Polypyrrole(PPy)-MnO2-SWCNT-cotton thread multi-grade nanostructures prepared via a facile and reproducible three-step process ("Cable-Type Supercapacitors of Three-Dimensional Cotton Thread Based Multi-Grade Nanostructures for Wearable Energy Storage"). | |

|

|

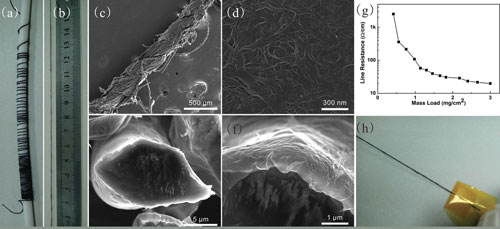

| Optical images of a two-meter-long SWCNTs coated cotton thread (a) wound on a Teflon rod, and (b) the same thread in a stretched state. (c) SEM image of SWCNTs coated cotton thread revealing its macroporous structure. (d) High-magnification SEM image showing the uniform coating of SWCNT cross-linked networks. (e) and (f) Cross-sectional SEM images of a SWCNTs coated microfibril. (g) The relationship between line resistance and mass loading of SWCNT. (h) SWCNTs coated cotton thread during passing the tape test, indicating strong adhesion and mechanical rigidity. (Reprinted with permission from Wiley-VCH Verlag) (click image to enlarge) | |

| To fabricate their electrodes, the team dipped cotton threads into a specially prepared single-walled carbon nanotube (SWCNT) ink and then dried them in an oven. They achieved a highly conductive fiber (with a line resistance of less than 20Ω cm-1)through this simple dipping and drying process. This fiber exhibited a high degree of flexibility and foldability. Also, The amount of SWCNTs coating can be easily controlled by the dipping time change and ink concentration. | |

| In a subsequent step, the researchers grew MnO2 nanostructures and PPy film onto the SWCNT coated cotton threads via electrochemical deposition process. | |

| "MnO2 is one of the most promising pseudocapactive materials for supercapacitors because of its high theoretical specific capacitance (1370F g-1 ), environmental friendliness, low-cost and natural abundance," the team writes. "However, unfortunately, the poor electrical and ionic conductivity of MnO2 usually depresses its capacitor performance." | |

| Meanwhile, PPy is a common conductive polymer with high conductivity and specific capacitance, which makes it suitable for conductive wrapping on a supercapacitor electrode. | |

| Therefore, the team in situ deposited a thin film of PPy on the surface of MnO2 nanostructures and SWCNTs to improve the electrical conductivity and electrochemical performance of the entire electrode system. | |

| According to the researchers, the resulting three-dimensional PPy-MnO2-SWCNT-cotton thread multi-grade nanostructures show outstanding mechanical and electrochemical properties: "Besides conducting SWCNT backbone, active mesoporous flower-like MnO2 nanoplates, PPy conductive wrapping layer could also play a very important role in the energy storage process, via improving the electrical conductivity and acting as pseudocapacitance material simultaneously." | |

| Besides, the unique three-dimensional porous structure accelerates the intercalation and deintercalation velocity of electrolyte ions into the active materials, enhancing the electrochemical performance further. | |

| During experiments, these supercapacitors exhibited high areal capacitance, stable cycling life, remarkable flexibility, high energy and power density – making them a promising candidate for cable type supercapacitors and wearable electronics. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|