| Posted: Mar 03, 2015 | |

Lower cost, roll-to-roll production of carbon nanotube based supercapacitors |

|

| (Nanowerk Spotlight) Ultra- or supercapacitors are emerging as a key enabling storage technology for use in fuel-efficient transport as well as in renewable energy systems (for instance as power grid buffer). These devices combine the advantages of conventional capacitors – they can rapidly deliver high current densities on demand – and batteries – they can store a large amount of electrical energy. | |

| Supercapacitors offer an alternative source of energy to replace rechargeable batteries for various applications, such as power tools, mobile electronics, and electric vehicles. Although the energy density of capacitors is quite low compared to batteries, their power density is much higher, allowing them to provide bursts of electric energy that for instance can help electric cars to accelerate at comparable or better rates than traditional petrol-only engine vehicles, while achieving a significantly reduced fuel consumption (read more about supercapacitors and other nanotechnologies to mitigate global warming). | |

| "Among the various types of supercapacitors, carbon nanotube (CNT) based devices have shown an order of magnitude higher performance in terms of energy and power densities," Ramakrishna Podila, an Assistant Professor in the Department of Physics and Astronomy at Clemson University, tells Nanowerk. "The bottleneck for transferring this technology to the marketplace, however, is the lack of efficient and scalable nanomanufacturing methods." | |

| Reporting their findings in Applied Physics Letters ("Roll-to-roll production of spray coated N-doped carbon nanotube electrodes for supercapacitors"), Podila's team at Clemson University, in collaboration with Professor Apparao Rao's lab, has now developed a new scalable method to to directly spraycoat CNT-based supercapacitor electrodes. | |

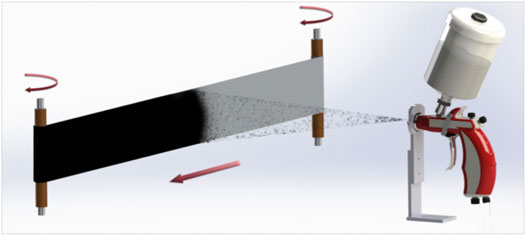

| "Much like painting a car or a wall in your home, we can spray CNT solutions on flexible electrodes, porous aluminum foils in our case, to achieve high energy density supercapacitor electrodes without the need of any binder," explains Podila. | |

| The resulting supercapacitors have a 10 times higher energy density compared to the state-of-the-art supercapacitors on the market. | |

|

|

| A schematic showing the facile roll-to-roll spray coating process for producing CNT-based supercapacitors with 10 times greater energy density at 17% cheaper than the state-of-the-art. (Image: Achyut J. Raghavendra) | |

| Theoretically, CNTs offer an ultra-high surface area; in practice, though, the net capacitance of the CNT electrodes is smaller than the predicted values – based on surface area – due to the presence of a so-called small quantum capacitance in series. | |

| In this work, the Clemson researchers together with Cornell Dubilier, Inc (a leading capacitor manufacturer in Liberty, SC) and Sai Global Technolgies (a newly founded manufacturer of tailored nanomaterials in San Antonio, TX), have demonstrated that nitrogen doped CNTs electrodes overcome the quantum capacitance limitations and exhibit high power density along with high energy density on par with thin film Li-ion batteries. | |

| "The quantum capacitance must be increased, ideally to infinity, for realizing the true potential of nanocarbons in energy storage," remarks Rao, who is director of the Clemson Nanomaterials Center. | |

| "Heteroatomic doping, which has been a valuable tool in the semiconductor industry, can provide a solution," adds Podila. "Here we showed that doping provides a handle to control the energy states where electrons could reside in supercapacitor electrode materials and thereby increase the quantum capacitance." | |

| The team points out that their supercapacitors show excellent cycle stability with very little degradation over at least 10000 cycles. | |

| "At the end point of the electrode lifetime, the CNTs from the used electrode could be recycled to make another new electrode," Rao notes. "The recycled electrode could perform as efficiently as 60% of the original method-a great advantage in terms of sustainability." | |

| Another advantage of the roll-to-roll spray-coating process is a significantly lower cost. As the researchers report, the final price of the spray coated CNT electrodes could be reduced by almost 17%, which includes material and production cost. | |

| "The industrial collaboration with Cornell Dubilier and Sai Global Technologies is a vital component of this research and is expected to translate the lab-based technology to the market place," note Podila and Rao. "We are thankful to the National Science Foundation for granting an award to undertake such projects which would have lasting impact on the global energy landscape." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|