Showing Spotlights 153 - 160 of 315 in category All (newest first):

The prospect of stretchable electronics opens some exciting possibilities - for instance, think about artificial skin with an integrated, stretchable touchscreen display. To get there, researchers have begun developing elastic electrical wiring that is both highly conductive and highly stretchable. Currently existing stretchable materials do already exhibit excellent conductivity and mechanical stretchability but they have one major disadvantage: their manufacturing processes are not readily scalable, which means it is difficult or cost-prohibitive to apply them to large-area electronics. A research team in Japan has now successfully fabricated, for the first time, novel elastic conductors that can be directly patterned by printing processes. This novel, printable elastic conductor comprises single-walled carbon nanotubes uniformly dispersed in a highly elastic fluorinated copolymer rubber.

The prospect of stretchable electronics opens some exciting possibilities - for instance, think about artificial skin with an integrated, stretchable touchscreen display. To get there, researchers have begun developing elastic electrical wiring that is both highly conductive and highly stretchable. Currently existing stretchable materials do already exhibit excellent conductivity and mechanical stretchability but they have one major disadvantage: their manufacturing processes are not readily scalable, which means it is difficult or cost-prohibitive to apply them to large-area electronics. A research team in Japan has now successfully fabricated, for the first time, novel elastic conductors that can be directly patterned by printing processes. This novel, printable elastic conductor comprises single-walled carbon nanotubes uniformly dispersed in a highly elastic fluorinated copolymer rubber.

May 20th, 2009

New work at the University of Arkansas has, for the very first time, demonstrated that Raman spectroscopy can be used to detect and monitor circulating carbon nanotubes in vivo and in real time. These findings could have a significant impact on the knowledge of how nanomaterials interact with living biological systems. Carbon nanotubes can be used for various advanced bio-medical applications. Before any clinical application of nanoparticles, it is imperative to determine critical in vivo parameters, namely pharmacological profiles including nanoparticle clearance rate from the circulation and their biodistribution in various tissue and organs. Until now, their distribution was only monitored by collecting samples after various time intervals, but this new research shows the ability of monitoring their concentration in vivo and in real time, while the animal is alive. Moreover, this work can be extended to the detection of circulating cancer cells that have been tagged by carbon nanotubes.

New work at the University of Arkansas has, for the very first time, demonstrated that Raman spectroscopy can be used to detect and monitor circulating carbon nanotubes in vivo and in real time. These findings could have a significant impact on the knowledge of how nanomaterials interact with living biological systems. Carbon nanotubes can be used for various advanced bio-medical applications. Before any clinical application of nanoparticles, it is imperative to determine critical in vivo parameters, namely pharmacological profiles including nanoparticle clearance rate from the circulation and their biodistribution in various tissue and organs. Until now, their distribution was only monitored by collecting samples after various time intervals, but this new research shows the ability of monitoring their concentration in vivo and in real time, while the animal is alive. Moreover, this work can be extended to the detection of circulating cancer cells that have been tagged by carbon nanotubes.

May 12th, 2009

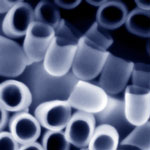

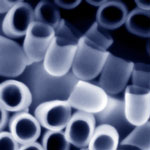

Many nanotechnology research efforts have explored the use of hollow nanochannels formed by carbon nanotubes (CNTs). However, the usually large length/diameter aspect ratio of CNTs has made it challenging to insert other materials into them in a controlled manner. A team of scientists has now developed the idea of using a nanocup morphology to solve this problem. The length/diameter ratio of these new graphitic architectures is 1,000 to 100,000 times smaller compared to conventional carbon nanotubes. This will allow researchers to build highly engineered and multicomponent functional nano building blocks for various applications including nanomedicine and nanometrology.

Many nanotechnology research efforts have explored the use of hollow nanochannels formed by carbon nanotubes (CNTs). However, the usually large length/diameter aspect ratio of CNTs has made it challenging to insert other materials into them in a controlled manner. A team of scientists has now developed the idea of using a nanocup morphology to solve this problem. The length/diameter ratio of these new graphitic architectures is 1,000 to 100,000 times smaller compared to conventional carbon nanotubes. This will allow researchers to build highly engineered and multicomponent functional nano building blocks for various applications including nanomedicine and nanometrology.

May 11th, 2009

Online breath analysis via an array of chemiresistive random network of single walled carbon nanotubes coated with organic materials showed excellent discrimination between the various breath states. An important implication of these findings, besides the detection of diseases directly related to the respiratory, cardiovascular, and renal systems, is the fact that volatile organic compounds are mainly blood borne and the concentration of biologically relevant substances in exhaled breath closely reflects that in the arterial system. Therefore, breath is predestined for monitoring different processes in the body. The excellent discrimination between the various breath states obtained in this study provides expectations for future capabilities for diagnosis, detection, and screening various stages of kidney disease, especially in the early stages of the disease, where it is possible to control blood pressure, fat, glucose and protein intake to slow the progression.

Online breath analysis via an array of chemiresistive random network of single walled carbon nanotubes coated with organic materials showed excellent discrimination between the various breath states. An important implication of these findings, besides the detection of diseases directly related to the respiratory, cardiovascular, and renal systems, is the fact that volatile organic compounds are mainly blood borne and the concentration of biologically relevant substances in exhaled breath closely reflects that in the arterial system. Therefore, breath is predestined for monitoring different processes in the body. The excellent discrimination between the various breath states obtained in this study provides expectations for future capabilities for diagnosis, detection, and screening various stages of kidney disease, especially in the early stages of the disease, where it is possible to control blood pressure, fat, glucose and protein intake to slow the progression.

May 7th, 2009

The use of gold nanoparticles in numerous biological and chemical nanotechnology applications experiences limitations due to the stability of the particles and their tendency for non-specific binding. One method to overcome these problems has been the use of carbon nanoshells to encapsulate gold and other noble metal particles. A graphene-like carbon shell is ideal for surface passivation of the metal nanoparticles for several reasons: it is nonreactive with the metallic surface; it provides unsurpassed stability; and it possesses a convenient handle for functionalization. A research team in the U.S. has now demonstrated a new fabrication method to encapsulate gold nanoparticles in a graphene-like carbon shell.

The use of gold nanoparticles in numerous biological and chemical nanotechnology applications experiences limitations due to the stability of the particles and their tendency for non-specific binding. One method to overcome these problems has been the use of carbon nanoshells to encapsulate gold and other noble metal particles. A graphene-like carbon shell is ideal for surface passivation of the metal nanoparticles for several reasons: it is nonreactive with the metallic surface; it provides unsurpassed stability; and it possesses a convenient handle for functionalization. A research team in the U.S. has now demonstrated a new fabrication method to encapsulate gold nanoparticles in a graphene-like carbon shell.

Apr 28th, 2009

Infrared (IR) detectors are used in imaging applications that include for instance medical diagnosis, environmental monitoring, space science, and security and military sensor devices. High-quality detectors require cryogenic cooling in order for the image not to be distorted by the detectors own radiation. This makes them expensive both to produce and to run. Although uncooled IR detectors are made, their resolution and image quality tend to be much lower than cooled detectors. It appears that carbon nanotubes (CNTs) could be used as novel IR detector material that would allow the fabrication of highly efficient detectors that do not require cooling. Researchers at Michigan State University have now, for the first time, experimentally demonstrated the design, manufacturing and experimental testing of an integrated nanoantenna concept for CNT based IR sensors.

Infrared (IR) detectors are used in imaging applications that include for instance medical diagnosis, environmental monitoring, space science, and security and military sensor devices. High-quality detectors require cryogenic cooling in order for the image not to be distorted by the detectors own radiation. This makes them expensive both to produce and to run. Although uncooled IR detectors are made, their resolution and image quality tend to be much lower than cooled detectors. It appears that carbon nanotubes (CNTs) could be used as novel IR detector material that would allow the fabrication of highly efficient detectors that do not require cooling. Researchers at Michigan State University have now, for the first time, experimentally demonstrated the design, manufacturing and experimental testing of an integrated nanoantenna concept for CNT based IR sensors.

Apr 22nd, 2009

Carbon nanotubes have been recognized as promising materials for catalysis, either as catalysts themselves, as catalyst additives or as catalyst supports. Researchers are particularly excited by the promise of single-walled carbon nanotubes as electrocatalysts or electron harvesting materials for electron-to-fuel conversion. Nanotubes act as catalysts when an electric current is passed through them. This enables them to donate electrons to molecules that come in contact with the reaction sites. In trying to explain carbon nanotubes' role as catalyst, scientist have long proposed that the reactive sites for catalysis can be discrete, specific sites rather then the entire sidewall of the nanotubes. But observing them directly has been challenging. A team at Cornell University has now filled in an important blank by pinpointing unique sites where the reactions take place on SWCNTs. The scientists showed that the reactions do not occur all along the tubes, but at the ends of the tubes or at defects along the tubes.

Carbon nanotubes have been recognized as promising materials for catalysis, either as catalysts themselves, as catalyst additives or as catalyst supports. Researchers are particularly excited by the promise of single-walled carbon nanotubes as electrocatalysts or electron harvesting materials for electron-to-fuel conversion. Nanotubes act as catalysts when an electric current is passed through them. This enables them to donate electrons to molecules that come in contact with the reaction sites. In trying to explain carbon nanotubes' role as catalyst, scientist have long proposed that the reactive sites for catalysis can be discrete, specific sites rather then the entire sidewall of the nanotubes. But observing them directly has been challenging. A team at Cornell University has now filled in an important blank by pinpointing unique sites where the reactions take place on SWCNTs. The scientists showed that the reactions do not occur all along the tubes, but at the ends of the tubes or at defects along the tubes.

Apr 21st, 2009

The field of printable electronics is already well established. The biggest limitation to further increasing the functionality of printed electronics devices is energy management, i.e. the space requirement and cost of batteries. Ideally, power and energy storage devices will be integrated into the manufacturing process to be printed at the same time. What is still needed to complement a further deveopment of printed electronics device technology are truly printable charge storage devices that can be easily fabricated using large-scale, solution-based, roll-to-roll processing, while still displaying good electrochemical performance. Only fully printable charge storage devices would allow for full integration into the manufacturing process of printed electronics.

The field of printable electronics is already well established. The biggest limitation to further increasing the functionality of printed electronics devices is energy management, i.e. the space requirement and cost of batteries. Ideally, power and energy storage devices will be integrated into the manufacturing process to be printed at the same time. What is still needed to complement a further deveopment of printed electronics device technology are truly printable charge storage devices that can be easily fabricated using large-scale, solution-based, roll-to-roll processing, while still displaying good electrochemical performance. Only fully printable charge storage devices would allow for full integration into the manufacturing process of printed electronics.

Apr 20th, 2009

The prospect of stretchable electronics opens some exciting possibilities - for instance, think about artificial skin with an integrated, stretchable touchscreen display. To get there, researchers have begun developing elastic electrical wiring that is both highly conductive and highly stretchable. Currently existing stretchable materials do already exhibit excellent conductivity and mechanical stretchability but they have one major disadvantage: their manufacturing processes are not readily scalable, which means it is difficult or cost-prohibitive to apply them to large-area electronics. A research team in Japan has now successfully fabricated, for the first time, novel elastic conductors that can be directly patterned by printing processes. This novel, printable elastic conductor comprises single-walled carbon nanotubes uniformly dispersed in a highly elastic fluorinated copolymer rubber.

The prospect of stretchable electronics opens some exciting possibilities - for instance, think about artificial skin with an integrated, stretchable touchscreen display. To get there, researchers have begun developing elastic electrical wiring that is both highly conductive and highly stretchable. Currently existing stretchable materials do already exhibit excellent conductivity and mechanical stretchability but they have one major disadvantage: their manufacturing processes are not readily scalable, which means it is difficult or cost-prohibitive to apply them to large-area electronics. A research team in Japan has now successfully fabricated, for the first time, novel elastic conductors that can be directly patterned by printing processes. This novel, printable elastic conductor comprises single-walled carbon nanotubes uniformly dispersed in a highly elastic fluorinated copolymer rubber.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed