Showing Spotlights 193 - 200 of 315 in category All (newest first):

The demand for the raw materials of the nanotechnology revolution - nanoparticles, carbon nanotubes, fullerenes, quantum dots, etc - is rising explosively and large chemical companies keep expanding their production capacities. These industrial scale systems often depend on precious input materials and energy-hogging processes. However, there are vast amounts of 'useless' natural materials literally lying around - rocks and stones - which could find their way into nanotechnology.Researchers in Germany have made a proof of concept demonstration that using natural nanostructures found in lava rocks is suitable for nanomaterial synthesis and for use in catalysis for production of butadiene and styrene.

The demand for the raw materials of the nanotechnology revolution - nanoparticles, carbon nanotubes, fullerenes, quantum dots, etc - is rising explosively and large chemical companies keep expanding their production capacities. These industrial scale systems often depend on precious input materials and energy-hogging processes. However, there are vast amounts of 'useless' natural materials literally lying around - rocks and stones - which could find their way into nanotechnology.Researchers in Germany have made a proof of concept demonstration that using natural nanostructures found in lava rocks is suitable for nanomaterial synthesis and for use in catalysis for production of butadiene and styrene.

Sep 2nd, 2008

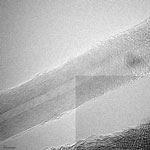

Carbon nanotubes (CNTs) have been hyped as the wunderkind material of the 21st century. And while researchers have developed numerous CNT applications, ranging from nanoelectronics to nanomedicine and military armor, the actual properties of CNTs fell way short of what the theory predicted. For instance, quantum mechanics calculations predict that defect-free single-walled carbon nanotubes possess a tensile strength of well over 100 gigapascals - which translates into the ability to endure weight of over 10,000 kg on a cable with a cross-section of 1 square millimeter. In practice, CNT tensile strength of only up to 28 GPa have been measured. The problem lies not so much with the actual CNTs but rather with the mechanical tests that have been employed so far. It is very difficult to produce testable samples without damaging the tubes (which in turn adversely affects their properties), and to image the test with high enough resolution to determine the exact nature of the fracture. First experimental measurements of the mechanical properties of carbon nanotubes have now been made that directly correspond to the theoretical predictions.

Carbon nanotubes (CNTs) have been hyped as the wunderkind material of the 21st century. And while researchers have developed numerous CNT applications, ranging from nanoelectronics to nanomedicine and military armor, the actual properties of CNTs fell way short of what the theory predicted. For instance, quantum mechanics calculations predict that defect-free single-walled carbon nanotubes possess a tensile strength of well over 100 gigapascals - which translates into the ability to endure weight of over 10,000 kg on a cable with a cross-section of 1 square millimeter. In practice, CNT tensile strength of only up to 28 GPa have been measured. The problem lies not so much with the actual CNTs but rather with the mechanical tests that have been employed so far. It is very difficult to produce testable samples without damaging the tubes (which in turn adversely affects their properties), and to image the test with high enough resolution to determine the exact nature of the fracture. First experimental measurements of the mechanical properties of carbon nanotubes have now been made that directly correspond to the theoretical predictions.

Aug 14th, 2008

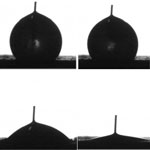

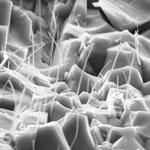

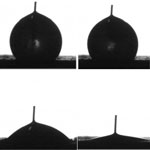

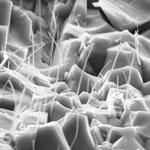

Generally, a surface either loves a liquid drop (then it's called solvophilic - wetting) or hates it (called solvophobic - repulsion) when it lands, depending on several parameters of both the surface - like geometric roughness asperities or ups and downs and chemical composition - and the liquid - like surface tension or tendency of solvation. When water is the liquid the terms hydrophilic and hydrophobic are used respectively for this and for oil similar terms like oleophilic and oleophobic. Advanced material engineering techniques can structure surfaces that allow dynamic tuning of their wettability all the way from superhydrophobic behavior to almost complete wetting - but these surfaces so far only work with high-surface-tension liquids. Just recently, researchers in India have developed a superhydrophobic (where the contact angle between the droplet and the surface is approaching 180 degrees) carbon nanotube (CNT) 'bucky paper' that shows fascinating wetting behavior as a result of an applied electric field, which could be remarkably tuned by changing key solution variables like ionic strength, nature of electrolyte, and pH of the droplet.

Generally, a surface either loves a liquid drop (then it's called solvophilic - wetting) or hates it (called solvophobic - repulsion) when it lands, depending on several parameters of both the surface - like geometric roughness asperities or ups and downs and chemical composition - and the liquid - like surface tension or tendency of solvation. When water is the liquid the terms hydrophilic and hydrophobic are used respectively for this and for oil similar terms like oleophilic and oleophobic. Advanced material engineering techniques can structure surfaces that allow dynamic tuning of their wettability all the way from superhydrophobic behavior to almost complete wetting - but these surfaces so far only work with high-surface-tension liquids. Just recently, researchers in India have developed a superhydrophobic (where the contact angle between the droplet and the surface is approaching 180 degrees) carbon nanotube (CNT) 'bucky paper' that shows fascinating wetting behavior as a result of an applied electric field, which could be remarkably tuned by changing key solution variables like ionic strength, nature of electrolyte, and pH of the droplet.

Aug 12th, 2008

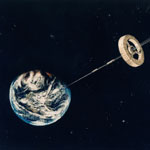

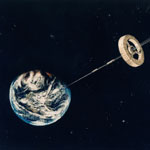

Our title today refers to the 1960 article by Yuri Artsutanov in Pravda: 'To the Cosmos by Electric Train'. This article is the granddaddy of all 'space elevator' concepts and first to propose the idea that a cable-based transport system could become an alternative to rockets for launching people and payload into space. The single most difficult task in building the Space Elevator is achieving the required tether strength-to-weight ratio - in other words, developing a material that is both strong enough and light enough to support the up to 100,000 km long tether. Thanks to nanotechnology, this material has become available in the form of carbon nanotubes (CNTs). The challenge ahead is to weave these raw CNTs into a useful form - a space worthy climbable ribbon. Assembling carbon nanotubes into commercially usable fibers is still one of the many challenges that nanotechnology researchers are faced with when trying to exploit the amazing properties of many nanomaterials.

Our title today refers to the 1960 article by Yuri Artsutanov in Pravda: 'To the Cosmos by Electric Train'. This article is the granddaddy of all 'space elevator' concepts and first to propose the idea that a cable-based transport system could become an alternative to rockets for launching people and payload into space. The single most difficult task in building the Space Elevator is achieving the required tether strength-to-weight ratio - in other words, developing a material that is both strong enough and light enough to support the up to 100,000 km long tether. Thanks to nanotechnology, this material has become available in the form of carbon nanotubes (CNTs). The challenge ahead is to weave these raw CNTs into a useful form - a space worthy climbable ribbon. Assembling carbon nanotubes into commercially usable fibers is still one of the many challenges that nanotechnology researchers are faced with when trying to exploit the amazing properties of many nanomaterials.

Aug 8th, 2008

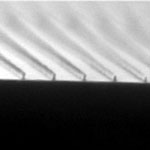

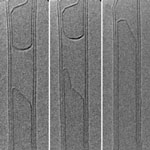

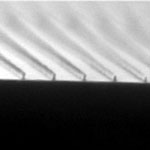

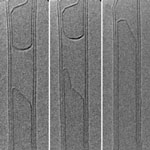

The success of the semiconductor industry has been due in large part to its ability to continuously increase the complexity, and therefore the processing power, of integrated circuits at a given manufacturing cost. Moore?s Law observes that the number of transistors in a computer chip doubles every two years, whilst the cost of making the chip remains the same, due to miniaturization of the components. In order to produce the next generation of computer chips it is necessary to continue to shrink the size of the components on the chip. The miniaturization upon which Moore?s Law rests has been achieved through advances in the photolithographic process used to pattern the components onto to the silicon wafer. A beam of light is projected through a shadow-casting reticule and the light pattern is then directed onto a silicon wafer coated with a photochemically sensitive material, known as a resist. The solubility of the resist is modified by exposure to the light, allowing specific areas of the resist film to be removed, whilst other areas remain as a mask, so that the silicon wafer can be selectively etched, metallized or doped. For many years it has been predicted that the end of photolithography is approaching, and that further miniaturization will require next generation lithography techniques, such as EUV lithography. However, photolithography has proved remarkably resilient, and continues to improve. Unfortunately, whilst the ability of photolithography to pattern small features continues to improve, the industry is beginning to challenge the capabilities of the photosensitive resist.

The success of the semiconductor industry has been due in large part to its ability to continuously increase the complexity, and therefore the processing power, of integrated circuits at a given manufacturing cost. Moore?s Law observes that the number of transistors in a computer chip doubles every two years, whilst the cost of making the chip remains the same, due to miniaturization of the components. In order to produce the next generation of computer chips it is necessary to continue to shrink the size of the components on the chip. The miniaturization upon which Moore?s Law rests has been achieved through advances in the photolithographic process used to pattern the components onto to the silicon wafer. A beam of light is projected through a shadow-casting reticule and the light pattern is then directed onto a silicon wafer coated with a photochemically sensitive material, known as a resist. The solubility of the resist is modified by exposure to the light, allowing specific areas of the resist film to be removed, whilst other areas remain as a mask, so that the silicon wafer can be selectively etched, metallized or doped. For many years it has been predicted that the end of photolithography is approaching, and that further miniaturization will require next generation lithography techniques, such as EUV lithography. However, photolithography has proved remarkably resilient, and continues to improve. Unfortunately, whilst the ability of photolithography to pattern small features continues to improve, the industry is beginning to challenge the capabilities of the photosensitive resist.

Aug 5th, 2008

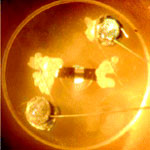

One of the best ways to gain control over synthesis of nanoparticles is to watch it happen. Take carbon nanotubes (CNTs): Synthesis of CNTs is a field that is growing explosively - but there is a lot that nanotechnology researchers don't know about how nanotubes form and grow. While there are a number of in situ characterization methods for nanotube synthesis under development worldwide, each with different strengths and weaknesses, much of the information about the nanotube structure is indirect.

Historically, in situ characterization tools have accelerated progress in synthesis for many advanced materials, and there is widespread recognition that in situ tools have the potential to improve CNT synthesis as well. Ideally one would like to detect individual nanotubes and ensembles as they grow and measure their physical properties while imposing minimal constraints on the synthesis method. In other words, with a good understanding of the synthesis process we would be better able to control the product.

One of the best ways to gain control over synthesis of nanoparticles is to watch it happen. Take carbon nanotubes (CNTs): Synthesis of CNTs is a field that is growing explosively - but there is a lot that nanotechnology researchers don't know about how nanotubes form and grow. While there are a number of in situ characterization methods for nanotube synthesis under development worldwide, each with different strengths and weaknesses, much of the information about the nanotube structure is indirect.

Historically, in situ characterization tools have accelerated progress in synthesis for many advanced materials, and there is widespread recognition that in situ tools have the potential to improve CNT synthesis as well. Ideally one would like to detect individual nanotubes and ensembles as they grow and measure their physical properties while imposing minimal constraints on the synthesis method. In other words, with a good understanding of the synthesis process we would be better able to control the product.

Aug 1st, 2008

Transparent conductive coatings pervade modern technology and they are a critical component of optoelectronic devices. Today, the most widely used standard coating in nearly all flat panel displays and microdisplays is indium tin oxide. As indium becomes increasingly scarce and expensive, the search for novel transparent electrode materials with good stability, high transparency and excellent conductivity has become a crucial goal for optoelectronic researchers. There are strong and successful efforts from several research groups around the world to develop optoelectronic devices on the basis of individual single-walled carbon nanotubes. This development is of great scientific interest, although there are major challenges in finding technologically feasible ways to assemble the individual nanotube devices into functioning electronic circuits with a high level of integration.

Transparent conductive coatings pervade modern technology and they are a critical component of optoelectronic devices. Today, the most widely used standard coating in nearly all flat panel displays and microdisplays is indium tin oxide. As indium becomes increasingly scarce and expensive, the search for novel transparent electrode materials with good stability, high transparency and excellent conductivity has become a crucial goal for optoelectronic researchers. There are strong and successful efforts from several research groups around the world to develop optoelectronic devices on the basis of individual single-walled carbon nanotubes. This development is of great scientific interest, although there are major challenges in finding technologically feasible ways to assemble the individual nanotube devices into functioning electronic circuits with a high level of integration.

Jul 28th, 2008

Having come a long way from pottery and tableware, modern advanced ceramics are high-performance materials that find use in things such as bio-medical implants, jet engine turbine blades, superconductors, missile nose cones, scratch-proof watches, or the heat protection tiles used on the Space Shuttle. Super-tough and ultra-high temperature resistant materials are in critical need for applications under extreme conditions such as jet engines, power turbines, catalytic heat exchangers, military armors, aircrafts, and spacecrafts. Structural ceramics have largely failed to fulfill their promise of revolutionizing engines with strong materials that withstand very high temperature. The major problem with the use of ceramics as structural materials is their brittleness. Although many attempts have been made to increase their toughness, including incorporation of fibers and particles, currently available ceramics and their composites are still not as tough as metals and polymers. The brittleness of ceramic materials has not yet been overcome and it has proven difficult to solve this problem by conventional material engineering approaches. The extraordinary mechanical properties of carbon nanotubes (CNTs) have generated strong research interest in their possible use in reinforced composite materials because incorporating CNTs into a ceramic matrix might be expected to produce tough as well as highly stiff and thermostable ceramic composites.

Having come a long way from pottery and tableware, modern advanced ceramics are high-performance materials that find use in things such as bio-medical implants, jet engine turbine blades, superconductors, missile nose cones, scratch-proof watches, or the heat protection tiles used on the Space Shuttle. Super-tough and ultra-high temperature resistant materials are in critical need for applications under extreme conditions such as jet engines, power turbines, catalytic heat exchangers, military armors, aircrafts, and spacecrafts. Structural ceramics have largely failed to fulfill their promise of revolutionizing engines with strong materials that withstand very high temperature. The major problem with the use of ceramics as structural materials is their brittleness. Although many attempts have been made to increase their toughness, including incorporation of fibers and particles, currently available ceramics and their composites are still not as tough as metals and polymers. The brittleness of ceramic materials has not yet been overcome and it has proven difficult to solve this problem by conventional material engineering approaches. The extraordinary mechanical properties of carbon nanotubes (CNTs) have generated strong research interest in their possible use in reinforced composite materials because incorporating CNTs into a ceramic matrix might be expected to produce tough as well as highly stiff and thermostable ceramic composites.

Jul 17th, 2008

The demand for the raw materials of the nanotechnology revolution - nanoparticles, carbon nanotubes, fullerenes, quantum dots, etc - is rising explosively and large chemical companies keep expanding their production capacities. These industrial scale systems often depend on precious input materials and energy-hogging processes. However, there are vast amounts of 'useless' natural materials literally lying around - rocks and stones - which could find their way into nanotechnology.Researchers in Germany have made a proof of concept demonstration that using natural nanostructures found in lava rocks is suitable for nanomaterial synthesis and for use in catalysis for production of butadiene and styrene.

The demand for the raw materials of the nanotechnology revolution - nanoparticles, carbon nanotubes, fullerenes, quantum dots, etc - is rising explosively and large chemical companies keep expanding their production capacities. These industrial scale systems often depend on precious input materials and energy-hogging processes. However, there are vast amounts of 'useless' natural materials literally lying around - rocks and stones - which could find their way into nanotechnology.Researchers in Germany have made a proof of concept demonstration that using natural nanostructures found in lava rocks is suitable for nanomaterial synthesis and for use in catalysis for production of butadiene and styrene.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed