| Posted: Jul 17, 2008 | |

A novel structure for carbon nanotube reinforced alumina composites |

|

| (Nanowerk Spotlight) Having come a long way from pottery and tableware, modern advanced ceramics are high-performance materials that find use in things such as bio-medical implants, jet engine turbine blades, superconductors, missile nose cones, scratch-proof watches, or the heat protection tiles used on the Space Shuttle. | |

| Super-tough and ultra-high temperature resistant materials are in critical need for applications under extreme conditions such as jet engines, power turbines, catalytic heat exchangers, military armors, aircrafts, and spacecrafts. Structural ceramics – which are very hard and resistant to heat and chemical attack – have largely failed to fulfill their promise of revolutionizing engines with strong materials that withstand very high temperature. The major problem with the use of ceramics as structural materials is their brittleness. Although many attempts have been made to increase their toughness, including incorporation of fibers and particles, currently available ceramics and their composites are still not as tough as metals and polymers. The brittleness of ceramic materials has not yet been overcome and it has proven difficult to solve this problem by conventional material engineering approaches. | |

| The extraordinary mechanical properties of carbon nanotubes (CNTs) have generated strong research interest in their possible use in reinforced composite materials because incorporating CNTs into a ceramic matrix might be expected to produce tough as well as highly stiff and thermostable ceramic composites. | |

| So far, different studies using carbon-nanotube reinforcements in ceramic composites have reported only small improvements in the bulk mechanical properties compared with traditional fiber-reinforced composites. The reason the use of CNTs in composites for structural applications has been disappointing is due to issues such as dispersion, alignment, and interfacial strength. | |

| New research coming out of Japan shows that a novel processing approach based on the precursor method can diminish the phase segregation of multi-walled carbon nanotubes (MWCNTs), render MWCNT/alumina composites highly homogeneous and as a result increase the strength and toughness of MWCNT/alumina composites. | |

| "It is well known that two particular problems exist in CNT/ceramic composite materials research" Dr. Go Yamamoto tells Nanowerk. "The first is the inhomogeneous dispersion of CNTs in the matrix. Pristine CNTs are well known for poor solubilization, which leads to phase segregation in the composite owing to the van der Waals attractive force. Severe structural inhomogeneities result in the degradation of the mechanical properties of the CNT composite materials. The second problem is the poor connectivity between CNTs and the ceramic matrix, which leads to a limited stress transfer capability from the matrix to the CNTs. The connectivity with the matrix, and uniform distribution within the matrix are essential structural requirements for the stronger and tougher CNT/ceramic composites." | |

| In this new study, Yamamoto, a Research Fellow of the Japan Society for the Promotion of Science and member of the Fracture and Reliability Research Institute at Tohoku University, together with collaborators from the university, show that a novel processing approach based on the precursor method can diminish the phase segregation of MWCNTs, and render MWCNT composites that are highly homogeneous. The results have been published in the June 24, 2008 online edition of Nanotechnology ("A novel structure for carbon nanotube reinforced alumina composites with improved mechanical properties"). | |

|

|

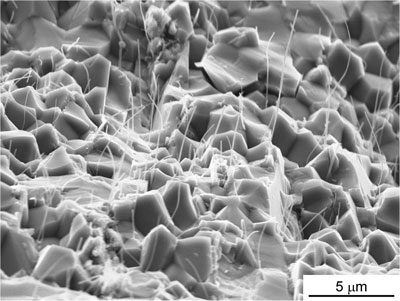

| Fracture surface of the acid-treated MWCNT/alumina composite. Numerous individual MWCNTs protrude from the fracture surface. (Image: Dr. Yamamoto, Tohoku University) | |

| Yamamoto points out that in the majority of previous studies, ceramic powders are mechanically mixed with CNTs in order to prepare CNT/alumina composites, which leads to severe structural inhomogeneities. In contrast, the MWCNTs used in this study are modified with an acid treatment. Combined with enhanced frictional resistance through the mechanical interlocks induced by the chemically modified MWCNTs, this approach leads to an increase in the strength and toughness of MWCNT/alumina composites. | |

| The researchers note that the rationale behind the acid treatment is to introduce nanoscale defects and adsorb negatively charged functional groups at the MWCNT ends and along their lengths. | |

| In order to obtain fully dense composites, the Tohoku team uses a spark plasma sintering method at a temperature of 1500 °C under a pressure of 20 MPa in vacuum for 10 min. | |

| "The connectivity with the matrix and uniform distribution within the matrix are structural requirements for stronger and tougher CNT/ceramic composites" says Yamamoto. "By utilizing the precursor method for synthesis of alumina and acid treatment of CNTs we have successfully demonstrated a novel processing approach that leads to stronger and tougher CNT/alumina composites." | |

| The scientists attribute the higher relative density and hardness for their acid-treated MWCNT/alumina composite – compared with a control sample of pristine MWCNT/alumina composites – to the more homogeneous distribution of MWCNTs in the sample. The addition of only 0.9 vol% acid-treated MWCNTs to alumina results in 27% and 25% simultaneous increases in bending strength and fracture toughness, respectively, indicating enhanced stress transfer capability from the alumina to the MWCNTs. | |

| The team also found that the addition of 0.9 vol% acid-treated MWCNTs to the alumina matrix increased the electrical conductivity of the composite by about 7-9 orders of magnitude compared with that of monolithic alumina. | |

| The Tohoku scientists expect that their acid-treated CNT/alumina composites may have potential applications as tribomaterials such as joint prosthesis and micro electro mechanical systems (MEMS) due the CNTs' good lubrication properties. | |

| More generally though, Yamamoto says that he expects the interfacial bonding between CNTs and ceramic matrices to be an important feature that has not yet been investigated and may point to a promising future for the application of MWCNTs in reinforcing structural ceramic components and other materials systems. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.