Showing Spotlights 257 - 264 of 624 in category All (newest first):

There are a wide range of passive devices such as beads, wells and tubes that can be used to capture and confine single cells. Previous active cell grippers with moving parts have relied on electrical modalities which can be challenging to implement off-chip and in a highly parallel manner. Researchers have now, for the first time, demonstrated an untethered active microgripper that can be used to capture and contain single cells.

There are a wide range of passive devices such as beads, wells and tubes that can be used to capture and confine single cells. Previous active cell grippers with moving parts have relied on electrical modalities which can be challenging to implement off-chip and in a highly parallel manner. Researchers have now, for the first time, demonstrated an untethered active microgripper that can be used to capture and contain single cells.

Jun 25th, 2014

A significant challenge in soft robotics involves fabricating soft sensors and actuators which, so far, have been very tedious to produce. Building soft sensors used by roboticists usually requires a multi-step, manual molding-lamination-sealing-infilling process. As a result, the design and fabrication process is cumbersome; the sensor form factors are unnecessarily limited; and there are issues with mechanical robustness. Now, though, researchers have demonstrated a new method for creating highly stretchable sensors based on embedded 3D printing of a carbon-based resistive ink within an elastomeric matrix.

A significant challenge in soft robotics involves fabricating soft sensors and actuators which, so far, have been very tedious to produce. Building soft sensors used by roboticists usually requires a multi-step, manual molding-lamination-sealing-infilling process. As a result, the design and fabrication process is cumbersome; the sensor form factors are unnecessarily limited; and there are issues with mechanical robustness. Now, though, researchers have demonstrated a new method for creating highly stretchable sensors based on embedded 3D printing of a carbon-based resistive ink within an elastomeric matrix.

Jun 24th, 2014

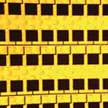

EUV lithography was first included in the next-generation lithography road maps in the early 90s, but after about 20 years it is not yet ready for prime time. In this article we briefly analyze the history of EUV in the last 2 decades and the situation as of today. Extreme ultraviolet technology posed and still poses formidable challenges as it is based on principles vastly different from conventional DUV (deep ultraviolet) lithography.

EUV lithography was first included in the next-generation lithography road maps in the early 90s, but after about 20 years it is not yet ready for prime time. In this article we briefly analyze the history of EUV in the last 2 decades and the situation as of today. Extreme ultraviolet technology posed and still poses formidable challenges as it is based on principles vastly different from conventional DUV (deep ultraviolet) lithography.

Apr 24th, 2014

Researchers have proposed an alternative way of making graphene from rice husk. This research, using an ordinary synthetic apparatus and abundant agricultural waste, suggest that low cost graphene materials could now be easily and cheaply synthesized on an industrial scale. Due to its abundance, risk husk has already received much attention as a starting material in generating high-value-added materials such as silica and porous carbon.

Researchers have proposed an alternative way of making graphene from rice husk. This research, using an ordinary synthetic apparatus and abundant agricultural waste, suggest that low cost graphene materials could now be easily and cheaply synthesized on an industrial scale. Due to its abundance, risk husk has already received much attention as a starting material in generating high-value-added materials such as silica and porous carbon.

Apr 7th, 2014

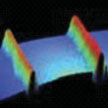

Flexible electronics is a rising field in terms of research and potential application opportunities to obtain similar characteristics than today's prevailing rigid electronics components. In new work, researchers have demonstrated the semiconductor industry's most advanced device architecture - FinFET, a new generation of device architecture which Intel has adopted in 2011 in their microprocessors; these field effect transistors offer non-planar three-dimensional topology where the channels are vertically aligned in arrays of ultra-thin silicon fins bordered by multiple gates - in a flexible platform using only industry standard processes and keeping the advantages offered by silicon.

Flexible electronics is a rising field in terms of research and potential application opportunities to obtain similar characteristics than today's prevailing rigid electronics components. In new work, researchers have demonstrated the semiconductor industry's most advanced device architecture - FinFET, a new generation of device architecture which Intel has adopted in 2011 in their microprocessors; these field effect transistors offer non-planar three-dimensional topology where the channels are vertically aligned in arrays of ultra-thin silicon fins bordered by multiple gates - in a flexible platform using only industry standard processes and keeping the advantages offered by silicon.

Mar 11th, 2014

The term printed electronics refers to the application of printing technologies for the fabrication of electronic circuits and devices, increasingly on flexible plastic or paper substrates. Traditionally, electronic devices are mainly manufactured by photolithography, vacuum deposition, and electroless plating processes. In contrast to these multistaged, expensive, and wasteful methods, inkjet printing offers a rapid and cheap way of printing electrical circuits with commodity inkjet printers and off-the-shelf materials.

The term printed electronics refers to the application of printing technologies for the fabrication of electronic circuits and devices, increasingly on flexible plastic or paper substrates. Traditionally, electronic devices are mainly manufactured by photolithography, vacuum deposition, and electroless plating processes. In contrast to these multistaged, expensive, and wasteful methods, inkjet printing offers a rapid and cheap way of printing electrical circuits with commodity inkjet printers and off-the-shelf materials.

Feb 27th, 2014

New work by an international team of researchers provides not only new insights into the chemical evolution of monodisperse nanoparticles from an atomic metal-dispersed precursor, but also a general route to obtain tunable nanoparticles as heterogeneous catalysts for chemical and material production. The team used an atomic metal-dispersed precursor of layered double hydroxides to synthesize high density, monodisperse metal nanoparticles. They then selected carbon nanotube growth as the probe reaction to evaluate the catalytic performance of the monodisperse metal nanoparticles catalysts.

New work by an international team of researchers provides not only new insights into the chemical evolution of monodisperse nanoparticles from an atomic metal-dispersed precursor, but also a general route to obtain tunable nanoparticles as heterogeneous catalysts for chemical and material production. The team used an atomic metal-dispersed precursor of layered double hydroxides to synthesize high density, monodisperse metal nanoparticles. They then selected carbon nanotube growth as the probe reaction to evaluate the catalytic performance of the monodisperse metal nanoparticles catalysts.

Feb 18th, 2014

Fabrication of three-dimensional (3D) objects through direct deposition of functional materials - also called additive manufacturing - has been a subject of intense study in the area of macroscale manufacturing for several decades. These 3D printing techniques are reaching a stage where desired products and structures can be made independent of the complexity of their shapes. Researchers in Korea have now shown that nanoscale 3D objects such as free-standing nanowalls can by constructed by an additive manufacturing scheme.

Fabrication of three-dimensional (3D) objects through direct deposition of functional materials - also called additive manufacturing - has been a subject of intense study in the area of macroscale manufacturing for several decades. These 3D printing techniques are reaching a stage where desired products and structures can be made independent of the complexity of their shapes. Researchers in Korea have now shown that nanoscale 3D objects such as free-standing nanowalls can by constructed by an additive manufacturing scheme.

Feb 5th, 2014

There are a wide range of passive devices such as beads, wells and tubes that can be used to capture and confine single cells. Previous active cell grippers with moving parts have relied on electrical modalities which can be challenging to implement off-chip and in a highly parallel manner. Researchers have now, for the first time, demonstrated an untethered active microgripper that can be used to capture and contain single cells.

There are a wide range of passive devices such as beads, wells and tubes that can be used to capture and confine single cells. Previous active cell grippers with moving parts have relied on electrical modalities which can be challenging to implement off-chip and in a highly parallel manner. Researchers have now, for the first time, demonstrated an untethered active microgripper that can be used to capture and contain single cells.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed