Showing Spotlights 25 - 32 of 34 in category All (newest first):

Sophisticated molecular-size motors have evolved in nature, where they are used in virtually every important biological process. Some fascinating examples in nature are DNA and RNA polymerase, rotary motors such as ATP synthase, and flagella motors. In contrast, the development of synthetic nanomotors that mimic the function of these amazing natural systems and could be used in man-made nanodevices is in its infancy. Nevertheless, scientists are making good progress in achieving cargo transport by artificial nanomachines although often these advances are handicapped by several drawbacks. Researchers in Germany have now demonstrated the directed loading and transport of microobjects by high propulsion powered tubular microbots driven by a microbubble propulsion mechanism.

Sophisticated molecular-size motors have evolved in nature, where they are used in virtually every important biological process. Some fascinating examples in nature are DNA and RNA polymerase, rotary motors such as ATP synthase, and flagella motors. In contrast, the development of synthetic nanomotors that mimic the function of these amazing natural systems and could be used in man-made nanodevices is in its infancy. Nevertheless, scientists are making good progress in achieving cargo transport by artificial nanomachines although often these advances are handicapped by several drawbacks. Researchers in Germany have now demonstrated the directed loading and transport of microobjects by high propulsion powered tubular microbots driven by a microbubble propulsion mechanism.

Aug 3rd, 2010

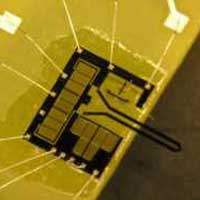

As the fields of bionanotechnologies develop, it will become possible one day to use biological nanodevices such as nanorobots for in situ and real-time in vivo diagnosis and therapeutic intervention of specific targets. A prerequisite for designing and constructing wireless biological nanorobots is the availability of an electrical source which can be made continuously available in the operational biological environment (i.e. the human body). Several possible sources - temperature displacement, kinetic energy derived from blood flow, and chemical energy released from biological motors inside the body - have been designed to provide the electrical sources that can reliably operate in body. Researchers now report the construction of a 980-nm laser-driven photovoltaic cell that can provide a sufficient power output even when covered by thick biological tissue layers.

As the fields of bionanotechnologies develop, it will become possible one day to use biological nanodevices such as nanorobots for in situ and real-time in vivo diagnosis and therapeutic intervention of specific targets. A prerequisite for designing and constructing wireless biological nanorobots is the availability of an electrical source which can be made continuously available in the operational biological environment (i.e. the human body). Several possible sources - temperature displacement, kinetic energy derived from blood flow, and chemical energy released from biological motors inside the body - have been designed to provide the electrical sources that can reliably operate in body. Researchers now report the construction of a 980-nm laser-driven photovoltaic cell that can provide a sufficient power output even when covered by thick biological tissue layers.

Dec 11th, 2009

Future nanomanufacturing processes will rely on two basic principles: a combination of chemical synthesis and self-assembly on one hand and robotic nanofabrication on the other. While the former is a controlled 'natural' process relying on chemistry and self-organization principles of nature, the latter will be an industrial process similar in concept to today's automated manufacturing assembly lines. Robotic assembly lines in modern factories have come a long way since the early 20th century when Henry Ford first used an assembly line on an industrial scale for his Model T automobile. Nevertheless, the principle is the same. Rather than having a single craftsman or team of craftsmen create each part of a product individually and assemble them together into a single item, an assembly line is a (often completely automated) manufacturing process in which interchangeable parts are added to a product in a sequential manner to create a finished product. While sporadic automation of certain tasks has already begun (for instance, automated microrobotic injection of foreign materials into biological cells), nanotechnology techniques today are pretty much where the industrial world was before Ford's assembly line - a domain of highly skilled artisans and not of automated mass production. It has long been a dream for nanotechnologists that robots could one day be used in an assembly line type of process to manufacture nanodevices. Researchers are beginning to develop the first rudimentary nanomanipulation devices that could lead to future automated manufacturing systems. Now, a team of scientists in Canada have reported the first demonstration of closed-loop force-controlled grasping at the nanonewton level.

Future nanomanufacturing processes will rely on two basic principles: a combination of chemical synthesis and self-assembly on one hand and robotic nanofabrication on the other. While the former is a controlled 'natural' process relying on chemistry and self-organization principles of nature, the latter will be an industrial process similar in concept to today's automated manufacturing assembly lines. Robotic assembly lines in modern factories have come a long way since the early 20th century when Henry Ford first used an assembly line on an industrial scale for his Model T automobile. Nevertheless, the principle is the same. Rather than having a single craftsman or team of craftsmen create each part of a product individually and assemble them together into a single item, an assembly line is a (often completely automated) manufacturing process in which interchangeable parts are added to a product in a sequential manner to create a finished product. While sporadic automation of certain tasks has already begun (for instance, automated microrobotic injection of foreign materials into biological cells), nanotechnology techniques today are pretty much where the industrial world was before Ford's assembly line - a domain of highly skilled artisans and not of automated mass production. It has long been a dream for nanotechnologists that robots could one day be used in an assembly line type of process to manufacture nanodevices. Researchers are beginning to develop the first rudimentary nanomanipulation devices that could lead to future automated manufacturing systems. Now, a team of scientists in Canada have reported the first demonstration of closed-loop force-controlled grasping at the nanonewton level.

Apr 25th, 2008

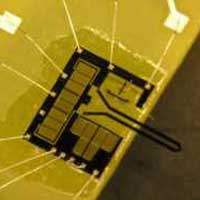

In our Nanowerk Spotlights we usually stay with both feet firmly on the grounds of science and shy away from the science fiction and sensationalist aspects of nanotechnology. So today's headline might come as a surprise to you (but just to be safe we put a question mark in). Of course, there are no nanobots yet, and won't be for a while, but one of the fundamental problems to be solved for possible future molecular machinery is the challenge of controlling many molecule-sized machines simultaneously to perform a desired task. Simple nanoscale motors have been realized over the past few years but these are systems that do nothing more than generate physical motion of their components at a nanoscale level. To build a true nanorobot - a completely self-contained electronic, electric, or mechanical device to do such activities as manufacturing at the nanoscale - many breakthrough advances will need to be achieved. One of them is the issue of controlling large numbers of devices, i.e. how to build and program the 'brains' of these machines. Another issue is to separate the concept of science fiction style 'thinking' robots (artificial intelligence) from a more realistic (yet still distant) concept of machines that can be programmed to perform a limited task in a more or less autonomous way for a period of time. These tasks could range from fabricating nanoscale components to performing medical procedures inside the body. For nanoscale machinery this would require the availability of nanoscale control units, i.e. computers. Researchers in Japan are now reporting a self organizing 16-bit parallel processing molecular assembly that brings us a step closer to building such a nanoscale processor.

In our Nanowerk Spotlights we usually stay with both feet firmly on the grounds of science and shy away from the science fiction and sensationalist aspects of nanotechnology. So today's headline might come as a surprise to you (but just to be safe we put a question mark in). Of course, there are no nanobots yet, and won't be for a while, but one of the fundamental problems to be solved for possible future molecular machinery is the challenge of controlling many molecule-sized machines simultaneously to perform a desired task. Simple nanoscale motors have been realized over the past few years but these are systems that do nothing more than generate physical motion of their components at a nanoscale level. To build a true nanorobot - a completely self-contained electronic, electric, or mechanical device to do such activities as manufacturing at the nanoscale - many breakthrough advances will need to be achieved. One of them is the issue of controlling large numbers of devices, i.e. how to build and program the 'brains' of these machines. Another issue is to separate the concept of science fiction style 'thinking' robots (artificial intelligence) from a more realistic (yet still distant) concept of machines that can be programmed to perform a limited task in a more or less autonomous way for a period of time. These tasks could range from fabricating nanoscale components to performing medical procedures inside the body. For nanoscale machinery this would require the availability of nanoscale control units, i.e. computers. Researchers in Japan are now reporting a self organizing 16-bit parallel processing molecular assembly that brings us a step closer to building such a nanoscale processor.

Mar 20th, 2008

Machines usually require various components such as bearings, gears, couplings or pistons. As machines shrink to the micro- and ultimately nanoscale, their components of course need to shrink with them. One of the major obstacles to the realization of intricate nanomachines like nanorobots is the lack of effective processes for building freestanding nanocomponents with specific shapes and sizes. Self-assembly methods produce both organic and inorganic nano-objects with high yields through 'bottom-up' approaches. The shapes, however, in most cases are confined to rather simple forms such as spheres, rods, triangles and cubes etc. and are not suitable for the elementary components of intricate nanomachines. Meanwhile, the 'top-down' approaches including electron beam lithography and micro-contact printing etc. focus on surface patterning or fabrication of suspended objects, although they can fabricate sophisticated nanostructures. So far, the fabrication and assembly of nano-objects with specific shapes and sizes that can act as elementary components for movable nanoelectromechanical systems (NEMS) is only at the conceptual stage. New research results coming from South Korea now offer the first step toward the realization of sophisticated nanomachines, designed to perform specific tasks, with overall dimensions comparable to those of biological cells.

Machines usually require various components such as bearings, gears, couplings or pistons. As machines shrink to the micro- and ultimately nanoscale, their components of course need to shrink with them. One of the major obstacles to the realization of intricate nanomachines like nanorobots is the lack of effective processes for building freestanding nanocomponents with specific shapes and sizes. Self-assembly methods produce both organic and inorganic nano-objects with high yields through 'bottom-up' approaches. The shapes, however, in most cases are confined to rather simple forms such as spheres, rods, triangles and cubes etc. and are not suitable for the elementary components of intricate nanomachines. Meanwhile, the 'top-down' approaches including electron beam lithography and micro-contact printing etc. focus on surface patterning or fabrication of suspended objects, although they can fabricate sophisticated nanostructures. So far, the fabrication and assembly of nano-objects with specific shapes and sizes that can act as elementary components for movable nanoelectromechanical systems (NEMS) is only at the conceptual stage. New research results coming from South Korea now offer the first step toward the realization of sophisticated nanomachines, designed to perform specific tasks, with overall dimensions comparable to those of biological cells.

Dec 4th, 2007

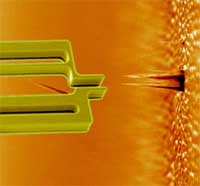

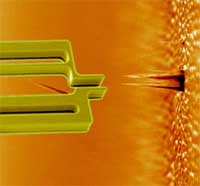

Hands-on nanotechnology: towards a nanorobotic assembly line (Nanowerk Spotlight) Until the twentieth century, a single craftsman or team of craftsmen would normally create each part of an industrial product individually and assemble them together into a single item, making changes in the parts so that they would fit together and work together; the so-called English System of manufacture. Then Henry Ford came along and in 1907-08 developed the assembly line for his Model T automobile. This innovation revolutionized not only industry but also our society because it allowed mass production of industrial goods at much lower cost than before. At its core, an assembly line is a manufacturing process in which interchangeable parts are added to a product in a sequential manner to create a finished product. Nanotechnology techniques today are pretty much where the industrial world was before Ford's assembly line - a domain of craftsmen and not of mass production. It has long been a dream for nanotechnologists that robots could one day be used in a similar way to produce nanodevices. A group of researchers from Denmark and Germany have now developed the rudimentary beginnings of the nanotechnology equivalent of an assembly line. They have shown 'pick-and-place' assembly of a working device using a silicon gripper - a robotic 'hand' some 10000 times smaller than a human hand. This nanogripper, controlled by a nanorobotic arm, is capable of picking up a carbon nanofiber (CN) and fix it onto the tip of an atomic force microscope cantilever.

Hands-on nanotechnology: towards a nanorobotic assembly line (Nanowerk Spotlight) Until the twentieth century, a single craftsman or team of craftsmen would normally create each part of an industrial product individually and assemble them together into a single item, making changes in the parts so that they would fit together and work together; the so-called English System of manufacture. Then Henry Ford came along and in 1907-08 developed the assembly line for his Model T automobile. This innovation revolutionized not only industry but also our society because it allowed mass production of industrial goods at much lower cost than before. At its core, an assembly line is a manufacturing process in which interchangeable parts are added to a product in a sequential manner to create a finished product. Nanotechnology techniques today are pretty much where the industrial world was before Ford's assembly line - a domain of craftsmen and not of mass production. It has long been a dream for nanotechnologists that robots could one day be used in a similar way to produce nanodevices. A group of researchers from Denmark and Germany have now developed the rudimentary beginnings of the nanotechnology equivalent of an assembly line. They have shown 'pick-and-place' assembly of a working device using a silicon gripper - a robotic 'hand' some 10000 times smaller than a human hand. This nanogripper, controlled by a nanorobotic arm, is capable of picking up a carbon nanofiber (CN) and fix it onto the tip of an atomic force microscope cantilever.

Sep 11th, 2007

Vaccination has resulted in the eradication of smallpox and control of measles, rubella, tetanus, diphtheria, and other infectious diseases in many areas of the world (at least where vaccines are available and affordable; providing vaccines to many parts of the developing world still is one of the basic medical needs that is far from being met). The basic idea of vaccination (the word comes from the Latin vacca - cow - because the first vaccine was derived from a virus affecting cows) is to inject weakened or killed forms of pathogens such as bacteria or viruses into the body in order for the immune system to develop antibodies against them; if the same types of microorganisms enter the body again, they will be destroyed by the antibodies. About 25 years ago, the basic idea of vaccination gave rise to bactofection - the technique of using bacteria as non-viral gene carriers into target cells. The DNA cargo is transported inside the bacteria and, once it arrives at the target location, the bacteria is broken up in order to release the therapeutic gene or protein. A novel technique takes advantage of the invasive properties of bacteria for delivery of nanoparticles into cells. Here, the gene or cargo is not carried inside the bacteria, but rather remains on the surface conjugated to nanoparticles. Consequently, this approach does not require bacterial disruption for delivery, or any genetic engineering of the bacteria for different cargo.

Vaccination has resulted in the eradication of smallpox and control of measles, rubella, tetanus, diphtheria, and other infectious diseases in many areas of the world (at least where vaccines are available and affordable; providing vaccines to many parts of the developing world still is one of the basic medical needs that is far from being met). The basic idea of vaccination (the word comes from the Latin vacca - cow - because the first vaccine was derived from a virus affecting cows) is to inject weakened or killed forms of pathogens such as bacteria or viruses into the body in order for the immune system to develop antibodies against them; if the same types of microorganisms enter the body again, they will be destroyed by the antibodies. About 25 years ago, the basic idea of vaccination gave rise to bactofection - the technique of using bacteria as non-viral gene carriers into target cells. The DNA cargo is transported inside the bacteria and, once it arrives at the target location, the bacteria is broken up in order to release the therapeutic gene or protein. A novel technique takes advantage of the invasive properties of bacteria for delivery of nanoparticles into cells. Here, the gene or cargo is not carried inside the bacteria, but rather remains on the surface conjugated to nanoparticles. Consequently, this approach does not require bacterial disruption for delivery, or any genetic engineering of the bacteria for different cargo.

Aug 14th, 2007

Science fiction style robots like Star Wars' R2-D2 or the NS-5 model in I, Robot firmly belong into the realm of Hollywood - and so do "nanobots" a la Michael Crichton's Prey. Staying with both feet firmly on scientific ground, robotics can be defined as the theory and application of robots, a completely self-contained electronic, electric, or mechanical device, to such activities as manufacturing. Scale that robot down to a few billionth of a meter and you are talking nanotechnology robotics; nanorobotics in short. The field of nanorobotics brings together several disciplines, including nanofabrication processes used for producing nanoscale robots, nanoactuators, nanosensors, and physical modeling at nanoscales. Nanorobotic manipulation technologies, including the assembly of nanometer-sized parts, the manipulation of biological cells or molecules, and the types of robots used to perform these tasks also form a component of nanorobotics. Nanorobotics might one day even lead to the holy grail of nanotechnology where automated and self-contained molecular assemblers not only are capable of building complex molecules but build copies of themselves - "self-replication" - or even complete everyday products (this vision is nicely illustrated in the clip "Productive Nanosystems: From Molecules to Superproducts"). Whether this will ever happen is hotly debated - to understand where both sides stand, read the famous 2003 debate where Drexler and Smalley make the case for and against molecular assemblers. Today's nanorobotics research deals with more mundane issues such as how to build nanoscale motors and simple nanomanipulators.

Science fiction style robots like Star Wars' R2-D2 or the NS-5 model in I, Robot firmly belong into the realm of Hollywood - and so do "nanobots" a la Michael Crichton's Prey. Staying with both feet firmly on scientific ground, robotics can be defined as the theory and application of robots, a completely self-contained electronic, electric, or mechanical device, to such activities as manufacturing. Scale that robot down to a few billionth of a meter and you are talking nanotechnology robotics; nanorobotics in short. The field of nanorobotics brings together several disciplines, including nanofabrication processes used for producing nanoscale robots, nanoactuators, nanosensors, and physical modeling at nanoscales. Nanorobotic manipulation technologies, including the assembly of nanometer-sized parts, the manipulation of biological cells or molecules, and the types of robots used to perform these tasks also form a component of nanorobotics. Nanorobotics might one day even lead to the holy grail of nanotechnology where automated and self-contained molecular assemblers not only are capable of building complex molecules but build copies of themselves - "self-replication" - or even complete everyday products (this vision is nicely illustrated in the clip "Productive Nanosystems: From Molecules to Superproducts"). Whether this will ever happen is hotly debated - to understand where both sides stand, read the famous 2003 debate where Drexler and Smalley make the case for and against molecular assemblers. Today's nanorobotics research deals with more mundane issues such as how to build nanoscale motors and simple nanomanipulators.

Apr 5th, 2007

Sophisticated molecular-size motors have evolved in nature, where they are used in virtually every important biological process. Some fascinating examples in nature are DNA and RNA polymerase, rotary motors such as ATP synthase, and flagella motors. In contrast, the development of synthetic nanomotors that mimic the function of these amazing natural systems and could be used in man-made nanodevices is in its infancy. Nevertheless, scientists are making good progress in achieving cargo transport by artificial nanomachines although often these advances are handicapped by several drawbacks. Researchers in Germany have now demonstrated the directed loading and transport of microobjects by high propulsion powered tubular microbots driven by a microbubble propulsion mechanism.

Sophisticated molecular-size motors have evolved in nature, where they are used in virtually every important biological process. Some fascinating examples in nature are DNA and RNA polymerase, rotary motors such as ATP synthase, and flagella motors. In contrast, the development of synthetic nanomotors that mimic the function of these amazing natural systems and could be used in man-made nanodevices is in its infancy. Nevertheless, scientists are making good progress in achieving cargo transport by artificial nanomachines although often these advances are handicapped by several drawbacks. Researchers in Germany have now demonstrated the directed loading and transport of microobjects by high propulsion powered tubular microbots driven by a microbubble propulsion mechanism.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed