| Sep 21, 2023 | |

MXene-enhanced hydrogel sensors for wearable technologies and human-machine interfaces |

|

| (Nanowerk Spotlight) Hydrogel materials show great promise for developing next-generation wearable sensors due to their flexibility, biocompatibility and tunable electrical properties. However, it remains challenging for hydrogel sensors to achieve high sensitivity while maintaining robust mechanical stretchability and stability in changing environments. | |

| Now, scientists from multiple Chinese institutions have reported a Kirigami-inspired strategy to significantly boost the strain sensitivity of conductive polymer hydrogels without compromising their stretchability and moisture retention. | |

| Their findings, reported in Advanced Functional Materials ("Kirigami-Inspired 3D-Printable MXene Organohydrogels for Soft Electronics"), could open doors for hydrogel sensors in diverse applications including remote healthcare monitoring, underwater object manipulation, and motion-controlled interfaces. | |

|

|

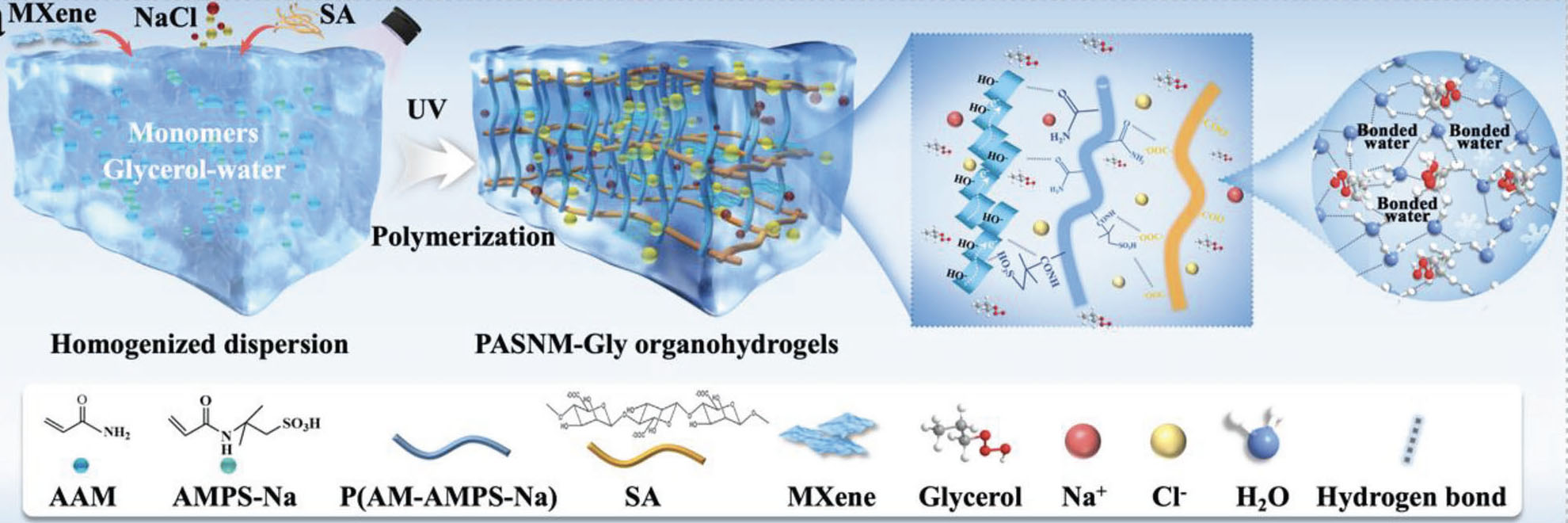

| Schematic illustrations of fabrication of organohydrogels and Kirigami-inspired structures, as well as the performance of the fabricated devices. (Reprinted with permission by Wiley-VCH Verlag) | |

| The fundamental dilemma in conventional hydrogel sensors is that enhancing electrical sensitivity typically requires incorporating more metallic particles or other conductive nanomaterials. This inadvertently makes the gels stiffer and less stretchable. Efforts to improve stretchability often rely on special molecular designs and crosslinking, but they tend to reduce sensitivity and stability. | |

| To overcome these limitations, the researchers fabricated a multifunctional hydrogel using a three-dimensional (3D) printable ink. It contained a covalently crosslinked polyacrylamide network to confer elasticity, cellulose nanofibers for mechanical reinforcement, conductive MXene nanoflakes for high sensitivity, and a glycerol-water mixture to retain moisture. | |

| This novel hydrogel composition showed excellent mechanical properties, with over 5000% stretchability, good ductility and a tensile strength of 224 kPa. Its electrical conductivity and moisture retention were also significantly higher compared to traditional hydrogels. For sensing strain, it achieved a maximum gauge factor of 21.5, superior to previous hydrogel sensors. But an even greater enhancement in sensitivity came from introducing Kirigami-inspired cut patterns into the 3D-printed hydrogel structures. | |

| Kirigami utilizes periodic slit patterns to create highly stretchable thin films and substrates. By optimizing the geometric designs, the researchers induced controlled separation of the slits as the hydrogel was strained. This further increased the electrical resistance changes in a nonlinear fashion. Their best Kirigami hydrogel sensor reached a remarkable gauge factor of 29.1 in the high strain range, 5.5 times higher than the unstructured hydrogel. It also showed excellent dynamic response, stability over thousands of cycles and a fast recovery time of around 50 milliseconds. | |

| Impressively, these Kirigami hydrogel sensors enabled a range of unique applications. Integrated into a glove device, they allowed precise control of an industrial robotic arm to grab objects underwater. This demonstrates their viability for interactive human-machine interfaces. The team also created a wearable system that accurately distinguished finger motions transmitting different Morse code signs. After training a recurrent neural network model, the monitored signals could be translated into speech in real-time with an accuracy exceeding 99%. Such motion-based silent communication could assist paralysis patients. | |

| With further development, these soft and highly sensitive Kirigami hydrogel sensors may find widespread use in medical diagnostics, sports monitoring, soft robotics or other emerging technologies requiring electromechanical transduction on the skin or within the human body. The researchers say their 3D printing approach allows easy customization of the sensor shapes, structures and dimensions. | |

| And the novel concept of merging optimized molecular designs with Kirigami architecture could also be extended to other functional gel systems. While more work is still needed to improve the integration and durability for long-term usage, this study demonstrates a versatile materials platform for efficient hydrogel-based sensing. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|