Showing Spotlights 233 - 240 of 315 in category All (newest first):

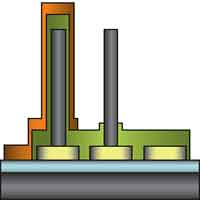

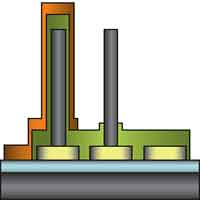

A memory chip is an integrated circuit made of millions of transistors and capacitors. In the most common form of computer memory, dynamic random access memory (DRAM), a transistor and a capacitor are paired to create one memory cell, which represents a single bit of data. The capacitor holds the bit of information, either a 0 or a 1. The transistor acts as a switch that lets the control circuitry on the memory chip read the capacitor or change its state. Because each bit stored in a chip is controlled by one transistor, memory capacities tend to expand at the same pace as the number of transistors per chip - which still follows Moore's Law and therefore currently doubles every 18 months. The problem is that the capacitor - consisting of two charged layers separated by an insulator - can shrink only so far. The thinner insulators get the more they allow charges to tunnel through. Tunneling increases the leakage current, and therefore the standby power consumption. Eventually the insulator will break down. Researchers have been trying to develop electromechanically driven switches that can be made small enough to be an alternative to transistor-switched silicon-based memory. Electromechanical devices are suitable for memory applications because of their excellent ON-OFF ratios and fast switching characteristics. With a mechanical switch there is physical separation of the switch from the capacitor. This makes the data leakage problem much less severe. Unfortunately they involve larger cells and more complex fabrication processes than silicon-based arrangements and therefore have not been so far an alternative to scaling down beyond semiconductor transistors. Researchers now have reported a novel nanoelectromechanical (NEM) switched capacitor structure based on vertically aligned multiwalled carbon nanotubes (CNTs) in which the mechanical movement of a nanotube relative to a carbon nanotube based capacitor defines ON and OFF states.

A memory chip is an integrated circuit made of millions of transistors and capacitors. In the most common form of computer memory, dynamic random access memory (DRAM), a transistor and a capacitor are paired to create one memory cell, which represents a single bit of data. The capacitor holds the bit of information, either a 0 or a 1. The transistor acts as a switch that lets the control circuitry on the memory chip read the capacitor or change its state. Because each bit stored in a chip is controlled by one transistor, memory capacities tend to expand at the same pace as the number of transistors per chip - which still follows Moore's Law and therefore currently doubles every 18 months. The problem is that the capacitor - consisting of two charged layers separated by an insulator - can shrink only so far. The thinner insulators get the more they allow charges to tunnel through. Tunneling increases the leakage current, and therefore the standby power consumption. Eventually the insulator will break down. Researchers have been trying to develop electromechanically driven switches that can be made small enough to be an alternative to transistor-switched silicon-based memory. Electromechanical devices are suitable for memory applications because of their excellent ON-OFF ratios and fast switching characteristics. With a mechanical switch there is physical separation of the switch from the capacitor. This makes the data leakage problem much less severe. Unfortunately they involve larger cells and more complex fabrication processes than silicon-based arrangements and therefore have not been so far an alternative to scaling down beyond semiconductor transistors. Researchers now have reported a novel nanoelectromechanical (NEM) switched capacitor structure based on vertically aligned multiwalled carbon nanotubes (CNTs) in which the mechanical movement of a nanotube relative to a carbon nanotube based capacitor defines ON and OFF states.

Jan 10th, 2008

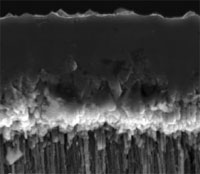

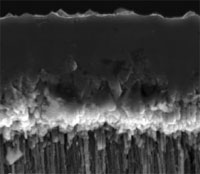

In most mechanical systems, friction or vibration are often considered to be negative attributes because they results in wear and unnecessary energy dissipation. Tribological issues such as friction, wear, and vibration have always plagued developers of small-scale mechanical devices. As devices get smaller and even reach the nanoscale, this problem becomes more acute due to the extreme surface-to-volume ratios these devices have. In nanomachines damage to even a single atom layer could mean disaster. Nanotechnology researchers basically have two ways to address this problem: they either could apply traditional tribological methods by trying to integrate dampers and low-friction materials with their nano- and microdevices - which becomes increasingly complex and costly at the nanoscale - or they could try and develop intrinsic damping materials that have hard, low-fiction surfaces to lower wear yet still maintain high compressibility and elastic properties to provide resistance to vibrations and shocks. Finding materials that address these problems individually is not difficult but fabricating a structure that combines all of them is nearly impossible because of the conflicting nature of these attributes. However, in what researchers have dubbed a 'nanomattress', a unique structure containing aligned carbon nanotubes (CNTs) covered with a hard layer of diamond-like carbon (DLC) results in a carbon-based composite material with outstanding mechanical properties.

In most mechanical systems, friction or vibration are often considered to be negative attributes because they results in wear and unnecessary energy dissipation. Tribological issues such as friction, wear, and vibration have always plagued developers of small-scale mechanical devices. As devices get smaller and even reach the nanoscale, this problem becomes more acute due to the extreme surface-to-volume ratios these devices have. In nanomachines damage to even a single atom layer could mean disaster. Nanotechnology researchers basically have two ways to address this problem: they either could apply traditional tribological methods by trying to integrate dampers and low-friction materials with their nano- and microdevices - which becomes increasingly complex and costly at the nanoscale - or they could try and develop intrinsic damping materials that have hard, low-fiction surfaces to lower wear yet still maintain high compressibility and elastic properties to provide resistance to vibrations and shocks. Finding materials that address these problems individually is not difficult but fabricating a structure that combines all of them is nearly impossible because of the conflicting nature of these attributes. However, in what researchers have dubbed a 'nanomattress', a unique structure containing aligned carbon nanotubes (CNTs) covered with a hard layer of diamond-like carbon (DLC) results in a carbon-based composite material with outstanding mechanical properties.

Nov 28th, 2007

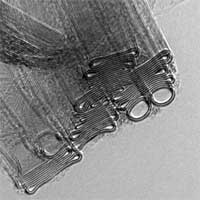

Just because hydrogen is a clean fuel doesn't mean that hydrogen production is a clean process. As more and more companies and investors jump onto the 'cleantech' bandwagon, hydrogen occupies an important place in this vision of a sustainable, carbon-free, and non-polluting energy future. If you look closer though, you'll find that you are not always told the full story about "clean" hydrogen. The U.S. department of Energy's Hydrogen Energy Roadmap foresees up to 90% of hydrogen production coming from fossil fuels - coal, gas, oil. In other words, a clean fuel is produced by the same dirty fuel that is causing all the problems we are facing today (read more in our recent Spotlight: Nanotechnology could clean up the hydrogen car's dirty little secret). Hydrogen can be produced in a clean way, of course, but the greatest challenge to clean hydrogen production is cost - so far, the cheapest way today to produce hydrogen is from fossil fuels. And as long as the political will and the resulting large-scale funding isn't there, this won't change. Unfortunately, large-scale deployment of artificial water-splitting technologies looks unlikely given the need for large amounts of expensive precious metals - such as platinum, which currently cost about $45,000 per kilogram, and which will become scarce at some point in the future - required to catalyze the multi electron water-splitting reactions. Intriguingly, there are mechanism of biological hydrogen activation found in nature and researchers have identified several microbes that can activate the dihydrogen bond through the catalytic activity of hydrogenases (enzymes that play a vital role in anaerobic metabolism). Scientists hope that these proteins could one day serve as catalysts for hydrogen production and oxidation in fuel cells. So far, their efforts have been hampered by the difficulty of incorporating these enzymes into electrical devices because the enzymes do not form good electrical connections with fuel cell components. New research now demonstrates the first successful electrical connection between a carbon nanotube and hydrogenase.

Just because hydrogen is a clean fuel doesn't mean that hydrogen production is a clean process. As more and more companies and investors jump onto the 'cleantech' bandwagon, hydrogen occupies an important place in this vision of a sustainable, carbon-free, and non-polluting energy future. If you look closer though, you'll find that you are not always told the full story about "clean" hydrogen. The U.S. department of Energy's Hydrogen Energy Roadmap foresees up to 90% of hydrogen production coming from fossil fuels - coal, gas, oil. In other words, a clean fuel is produced by the same dirty fuel that is causing all the problems we are facing today (read more in our recent Spotlight: Nanotechnology could clean up the hydrogen car's dirty little secret). Hydrogen can be produced in a clean way, of course, but the greatest challenge to clean hydrogen production is cost - so far, the cheapest way today to produce hydrogen is from fossil fuels. And as long as the political will and the resulting large-scale funding isn't there, this won't change. Unfortunately, large-scale deployment of artificial water-splitting technologies looks unlikely given the need for large amounts of expensive precious metals - such as platinum, which currently cost about $45,000 per kilogram, and which will become scarce at some point in the future - required to catalyze the multi electron water-splitting reactions. Intriguingly, there are mechanism of biological hydrogen activation found in nature and researchers have identified several microbes that can activate the dihydrogen bond through the catalytic activity of hydrogenases (enzymes that play a vital role in anaerobic metabolism). Scientists hope that these proteins could one day serve as catalysts for hydrogen production and oxidation in fuel cells. So far, their efforts have been hampered by the difficulty of incorporating these enzymes into electrical devices because the enzymes do not form good electrical connections with fuel cell components. New research now demonstrates the first successful electrical connection between a carbon nanotube and hydrogenase.

Nov 23rd, 2007

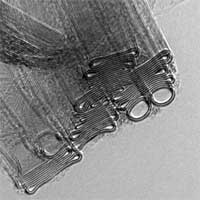

Tie a rock to the end of a piece of ribbon, then spin it over your head. It will be pulled taut as the rock circles about. Now, imagine a ribbon 62,000 miles long, anchored near the equator with a weight on the other end. The centrifugal force of the earth's rotation will make it behave the same way. You'll end up with not only the world's biggest nunchuck, but also a kind of elevator to outer space. A space elevator is one of those ideas from 1950s-style futurism that are so whacky they might just work. The single most difficult task in building the Space Elevator is achieving the required tether strength-to-weight ratio - in other words, developing a material that is both strong enough and light enough to support the 60,000 mile long tether. This material has become available in the form of carbon nanotubes (CNTs). The challenge ahead is to weave these raw CNTs into a useful form - a space worthy climbable ribbon. Assembling carbon nanotubes into commercially usable fibers is still one of the many challenges that nanotechnology researchers are faced with when trying to exploit the amazing properties of many nanomaterials. Apart from ambitious large-scale projects like the space elevator, CNT-based fibers will have many applications, from protective fabrics and coatings in military applications, higher performance materials for sports equipment to transparent conductive films and, eventually, as a replacement for copper wire in transmitting electrical power and signals. Researchers in the UK are making good progress in developing scalable fabrication techniques for high performance CNT fibers.

Tie a rock to the end of a piece of ribbon, then spin it over your head. It will be pulled taut as the rock circles about. Now, imagine a ribbon 62,000 miles long, anchored near the equator with a weight on the other end. The centrifugal force of the earth's rotation will make it behave the same way. You'll end up with not only the world's biggest nunchuck, but also a kind of elevator to outer space. A space elevator is one of those ideas from 1950s-style futurism that are so whacky they might just work. The single most difficult task in building the Space Elevator is achieving the required tether strength-to-weight ratio - in other words, developing a material that is both strong enough and light enough to support the 60,000 mile long tether. This material has become available in the form of carbon nanotubes (CNTs). The challenge ahead is to weave these raw CNTs into a useful form - a space worthy climbable ribbon. Assembling carbon nanotubes into commercially usable fibers is still one of the many challenges that nanotechnology researchers are faced with when trying to exploit the amazing properties of many nanomaterials. Apart from ambitious large-scale projects like the space elevator, CNT-based fibers will have many applications, from protective fabrics and coatings in military applications, higher performance materials for sports equipment to transparent conductive films and, eventually, as a replacement for copper wire in transmitting electrical power and signals. Researchers in the UK are making good progress in developing scalable fabrication techniques for high performance CNT fibers.

Nov 20th, 2007

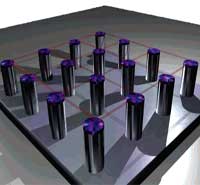

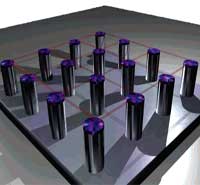

A team of researchers have come up with an inexpensive way of making complex networks of carbon nanotubes that can be stamped onto circuit boards. They were able to create an inexpensive and relatively simple method for creating these predefined networks. The scientists arranged silicon pillars in the shape of the network they wanted and then coated the top of the pillars with silicon dioxide. The suspended single-walled carbon nanotubes adhered to the tops of pillars, growing taut and straight. A Raman spectroscopy (RS) laser not only assigned specific properties to each individual nanotube, it was also capable of destroying any unwanted nanotubes.

A team of researchers have come up with an inexpensive way of making complex networks of carbon nanotubes that can be stamped onto circuit boards. They were able to create an inexpensive and relatively simple method for creating these predefined networks. The scientists arranged silicon pillars in the shape of the network they wanted and then coated the top of the pillars with silicon dioxide. The suspended single-walled carbon nanotubes adhered to the tops of pillars, growing taut and straight. A Raman spectroscopy (RS) laser not only assigned specific properties to each individual nanotube, it was also capable of destroying any unwanted nanotubes.

Nov 15th, 2007

Nanofluidic channels, confining and transporting tiny amounts of fluid, are the pipelines that make the cellular activities of organisms possible. Nanoscale channels carry nutrients into cells and waste from cells and they also transport water into and out of the cell. Body temperature, digestion, reproduction, fluid pressure in the eye, and water conservation in the kidney are only a few of the processes in humans that depend on the proper functioning of cellular water channels. Special proteins called aquaporins can transport water through the cell membrane at a high rate while effectively blocking everything else - even individual protons, the nuclei of hydrogen atoms. The aquaporin channels are so narrow that no molecule larger than water can pass through, effectively forcing them through like beads on a chain. A unique distribution of amino acid residues along the pore wall also accounts for the channel's ability to move water quickly. To keep out molecules smaller than water there is also a chemical filter, formed by the specific orientation and distribution of the amino acid residues lining the pore. Thus water, and only water, flows freely through the aquaporin nanochannels, the direction of flow depending only on changing relative pressure inside and outside the cell. This intriguing mechanism has attracted the attention of nanotechnology researchers who see it as a blueprint for the construction of nanoscale water pumps. A molecular dynamics simulation conducted by Chinese researchers proposes a design for such a molecular pump constructed with a carbon nanotube.

Nanofluidic channels, confining and transporting tiny amounts of fluid, are the pipelines that make the cellular activities of organisms possible. Nanoscale channels carry nutrients into cells and waste from cells and they also transport water into and out of the cell. Body temperature, digestion, reproduction, fluid pressure in the eye, and water conservation in the kidney are only a few of the processes in humans that depend on the proper functioning of cellular water channels. Special proteins called aquaporins can transport water through the cell membrane at a high rate while effectively blocking everything else - even individual protons, the nuclei of hydrogen atoms. The aquaporin channels are so narrow that no molecule larger than water can pass through, effectively forcing them through like beads on a chain. A unique distribution of amino acid residues along the pore wall also accounts for the channel's ability to move water quickly. To keep out molecules smaller than water there is also a chemical filter, formed by the specific orientation and distribution of the amino acid residues lining the pore. Thus water, and only water, flows freely through the aquaporin nanochannels, the direction of flow depending only on changing relative pressure inside and outside the cell. This intriguing mechanism has attracted the attention of nanotechnology researchers who see it as a blueprint for the construction of nanoscale water pumps. A molecular dynamics simulation conducted by Chinese researchers proposes a design for such a molecular pump constructed with a carbon nanotube.

Nov 9th, 2007

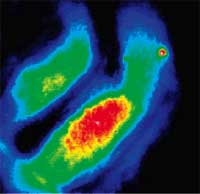

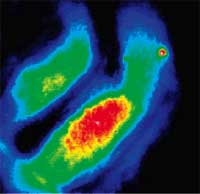

Nanotechnology's poster child, the carbon nanotube (CNT), has been explored for use in many technical applications. Increasingly, researchers are also looking at the unique biological properties of CNTs for potential biomedical uses. For instance, the interaction between DNA and CNTs have been explored and DNA-functionalized nanotubes hold significant promise as nucleic acid sensors. Nanotubes have also been considered for use as scaffolds for cells in tissue engineering. No matter what their intended function, any material used in medicine must exhibit - among other compatibility factors - biocompatibility, non-toxicity and non-carcinogenicity. And here the jury is still out as far as CNTs are concerned. One limiting factor of toxicological studies so far has been the use of animal tissue rather than living specimen. Researchers have now succeeded in detecting single-walled CNTs (SWCNTs) inside living animals - with surprisingly benign results - paving the way for future research on the effects and fate of nanotubes inside living organisms.

Nanotechnology's poster child, the carbon nanotube (CNT), has been explored for use in many technical applications. Increasingly, researchers are also looking at the unique biological properties of CNTs for potential biomedical uses. For instance, the interaction between DNA and CNTs have been explored and DNA-functionalized nanotubes hold significant promise as nucleic acid sensors. Nanotubes have also been considered for use as scaffolds for cells in tissue engineering. No matter what their intended function, any material used in medicine must exhibit - among other compatibility factors - biocompatibility, non-toxicity and non-carcinogenicity. And here the jury is still out as far as CNTs are concerned. One limiting factor of toxicological studies so far has been the use of animal tissue rather than living specimen. Researchers have now succeeded in detecting single-walled CNTs (SWCNTs) inside living animals - with surprisingly benign results - paving the way for future research on the effects and fate of nanotubes inside living organisms.

Nov 7th, 2007

Animals that cling to walls and walk on ceilings owe this ability to micro- and nanoscale attachment elements. The highest adhesion forces are encountered in geckos. For centuries, the ability of geckos to climb any vertical surface or hang from ceilings with one toe has always generated considerable interest. A gecko is the heaviest animal that can 'stand' on a ceiling, with its feet over its head. This is why scientists are intensely researching the adhesive system of the tiny hairs on its feet. On the sole of a gecko's toes there are some one billion tiny adhesive hairs called setae (3-130 micrometers in length), splitting into even smaller spatulae (about 200 nanometers in both width and length) at the end. It was found that these elastic hairs induce strong van der Waals forces. This finding has prompted many researchers to use synthetic microarrays to mimic gecko feet. Recent work, mainly from A. Dhinojwala, P.M. Ajayan, M. Meyyappan, and L. Dai groups, as well as the Max Planck Institute for Metals Research in Germany (see our previous Spotlight: Gecko nanotechnology), has indicated that aligned carbon nanotubes (CNTs) sticking out of substrate surfaces showed strong nanometer-scale adhesion forces. Although carbon nanotubes are thousands of times thinner than a human hair, they can be stronger than steel, lighter than plastic, more conductive than copper for electricity and diamond for heat. Applications of such bio-inspired development of artificial dry adhesive systems with aligned carbon nanotubes could range from low-tech fridge magnets to holding together electronics or even airplane parts.

Animals that cling to walls and walk on ceilings owe this ability to micro- and nanoscale attachment elements. The highest adhesion forces are encountered in geckos. For centuries, the ability of geckos to climb any vertical surface or hang from ceilings with one toe has always generated considerable interest. A gecko is the heaviest animal that can 'stand' on a ceiling, with its feet over its head. This is why scientists are intensely researching the adhesive system of the tiny hairs on its feet. On the sole of a gecko's toes there are some one billion tiny adhesive hairs called setae (3-130 micrometers in length), splitting into even smaller spatulae (about 200 nanometers in both width and length) at the end. It was found that these elastic hairs induce strong van der Waals forces. This finding has prompted many researchers to use synthetic microarrays to mimic gecko feet. Recent work, mainly from A. Dhinojwala, P.M. Ajayan, M. Meyyappan, and L. Dai groups, as well as the Max Planck Institute for Metals Research in Germany (see our previous Spotlight: Gecko nanotechnology), has indicated that aligned carbon nanotubes (CNTs) sticking out of substrate surfaces showed strong nanometer-scale adhesion forces. Although carbon nanotubes are thousands of times thinner than a human hair, they can be stronger than steel, lighter than plastic, more conductive than copper for electricity and diamond for heat. Applications of such bio-inspired development of artificial dry adhesive systems with aligned carbon nanotubes could range from low-tech fridge magnets to holding together electronics or even airplane parts.

Nov 5th, 2007

A memory chip is an integrated circuit made of millions of transistors and capacitors. In the most common form of computer memory, dynamic random access memory (DRAM), a transistor and a capacitor are paired to create one memory cell, which represents a single bit of data. The capacitor holds the bit of information, either a 0 or a 1. The transistor acts as a switch that lets the control circuitry on the memory chip read the capacitor or change its state. Because each bit stored in a chip is controlled by one transistor, memory capacities tend to expand at the same pace as the number of transistors per chip - which still follows Moore's Law and therefore currently doubles every 18 months. The problem is that the capacitor - consisting of two charged layers separated by an insulator - can shrink only so far. The thinner insulators get the more they allow charges to tunnel through. Tunneling increases the leakage current, and therefore the standby power consumption. Eventually the insulator will break down. Researchers have been trying to develop electromechanically driven switches that can be made small enough to be an alternative to transistor-switched silicon-based memory. Electromechanical devices are suitable for memory applications because of their excellent ON-OFF ratios and fast switching characteristics. With a mechanical switch there is physical separation of the switch from the capacitor. This makes the data leakage problem much less severe. Unfortunately they involve larger cells and more complex fabrication processes than silicon-based arrangements and therefore have not been so far an alternative to scaling down beyond semiconductor transistors. Researchers now have reported a novel nanoelectromechanical (NEM) switched capacitor structure based on vertically aligned multiwalled carbon nanotubes (CNTs) in which the mechanical movement of a nanotube relative to a carbon nanotube based capacitor defines ON and OFF states.

A memory chip is an integrated circuit made of millions of transistors and capacitors. In the most common form of computer memory, dynamic random access memory (DRAM), a transistor and a capacitor are paired to create one memory cell, which represents a single bit of data. The capacitor holds the bit of information, either a 0 or a 1. The transistor acts as a switch that lets the control circuitry on the memory chip read the capacitor or change its state. Because each bit stored in a chip is controlled by one transistor, memory capacities tend to expand at the same pace as the number of transistors per chip - which still follows Moore's Law and therefore currently doubles every 18 months. The problem is that the capacitor - consisting of two charged layers separated by an insulator - can shrink only so far. The thinner insulators get the more they allow charges to tunnel through. Tunneling increases the leakage current, and therefore the standby power consumption. Eventually the insulator will break down. Researchers have been trying to develop electromechanically driven switches that can be made small enough to be an alternative to transistor-switched silicon-based memory. Electromechanical devices are suitable for memory applications because of their excellent ON-OFF ratios and fast switching characteristics. With a mechanical switch there is physical separation of the switch from the capacitor. This makes the data leakage problem much less severe. Unfortunately they involve larger cells and more complex fabrication processes than silicon-based arrangements and therefore have not been so far an alternative to scaling down beyond semiconductor transistors. Researchers now have reported a novel nanoelectromechanical (NEM) switched capacitor structure based on vertically aligned multiwalled carbon nanotubes (CNTs) in which the mechanical movement of a nanotube relative to a carbon nanotube based capacitor defines ON and OFF states.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed