| Posted: Nov 28, 2007 | |

Carbon nanomattresses to provide tunable damping properties for nanodevices |

|

| (Nanowerk Spotlight) In most mechanical systems, friction or vibration are often considered to be negative attributes because they results in wear and unnecessary energy dissipation. Tribological issues such as friction, wear, and vibration have always plagued developers of small-scale mechanical devices. As devices get smaller and even reach the nanoscale, this problem becomes more acute due to the extreme surface-to-volume ratios these devices have. In nanomachines damage to even a single atom layer could mean disaster. Nanotechnology researchers basically have two ways to address this problem: they either could apply traditional tribological methods by trying to integrate dampers and low-friction materials with their nano- and microdevices - which becomes increasingly complex and costly at the nanoscale - or they could try and develop intrinsic damping materials that have hard, low-fiction surfaces to lower wear yet still maintain high compressibility and elastic properties to provide resistance to vibrations and shocks. Finding materials that address these problems individually is not difficult but fabricating a structure that combines all of them is nearly impossible because of the conflicting nature of these attributes. However, in what researchers have dubbed a 'nanomattress', a unique structure containing aligned carbon nanotubes (CNTs) covered with a hard layer of diamond-like carbon (DLC) results in a carbon-based composite material with outstanding mechanical properties. | |

| "We achieved an excellent candidate for an intrinsic damping material by combining highly elastic CNTs with a DLC film" Edwin H.T. Teo explained to Nanowerk. "Moreover, with damping dependant on tube density and the physical attributes of the CNTs, adaptations for various applications can be easily made by adjusting these parameters. As DLC and CNTs are wear- and chemical-resistant and inherently stable at high temperatures, the composites may find application as perfect environmental seals for micro- and nanodevices. This seal would not just protect the components from harsh environments but also provide mechanical vibration isolation and wear protection." | |

| Teo, a PhD student at the School of Electrical and Electronic Engineering at Nanyang Technological University in Singapore, is first author of a recent paper in Advanced Materials ("A Carbon Nanomattress: A New Nanosystem with Intrinsic, Tunable, Damping Properties") in which he and his supervisor Prof. Tay Beng Kang's together with collaborators from Prof. Daniel Chua's group report on how they obtained an entirely new class of compositional material through the fusion of two different forms of the same element (carbon). They termed this unique 'smart' material Carbon Nanomattress or CNM for short. | |

|

|

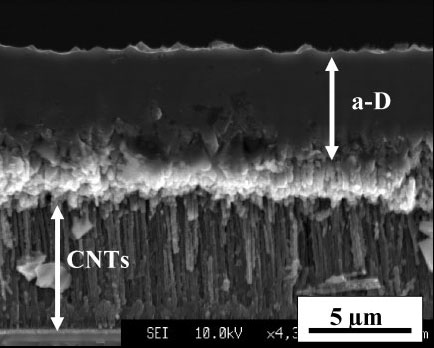

| Cross-sectional SEM image showing the composite film, which resembles a spring damping system where the CNTs act as shock- and energy-absorbing pillars that support the top, ultrahard, a-D ceiling. (Reprinted with permission from Wiley-VCH Verlag) | |

| "What we have with CNM is a new material that has superior wear resistance and yet still has damping properties" says Teo. "Probably the most important aspect of this composite is the ability to tune this damping behavior by adjusting the underlying carbon nanotube forest. Furthermore, with air or vacuum space trapped between the external environment and the a-D film – using the CNTs as spacers – a good degree of thermal isolation may also be expected from such composites." | |

| The researchers in Singapore believe this composite film could have far reaching applications in areas of nanotechnology especially in biological, space, and military technologies where survivability in harsh and hostile environments are essential to their function. | |

| The researchers point out that this is an entirely new material system. The novelty lies in its design and how it is made – using the same element in the construction of a hybrid material is quite an unconventional approach. "The approach of using carbon on carbon is simple and elegant in form and I am surprised it has not been done before" says Teo. | |

| The hybrid film was prepared by first growing a dense, vertically aligned, multi-walled CNT network (CNTs are ca. 7 µm long with 200 nm diameters) by thermal chemical vapor deposition on a conductive silicon substrate. | |

| "This prepared sample was then placed in our patented, off-plane, double-bend, filtered cathodic vacuum arc system with substrate pulse biasing to deposit a 5 µm a-D film on the surface of the CNTs" explains Teo. "In order to confine the coating to the top of the CNT film and prevent it from seeping through, we employed a negative substrate pulse bias. Because of the negative voltage pulse on the CNT substrate, the high-energy positive carbon ions were attracted primarily to the tips of the CNTs, forming a-D nanospheres." | |

| As these spheres increased in size, they coagulated into a thick, solid a-D film on top of the CNTs. Teo says that the top layer that formed in this manner adhered very well to the tips of the CNTs, as the carbon ions formed strong covalent C?C bonds to them. "With a hard, solid top, the nanomattress is now capable of distributing the forces applied to it uniformly to the underlying CNTs, which act like the springs of a mattress." | |

| Subsequent exposure of the obtained composite nanostructure to various structural and mechanical tests confirmed that the nanomattress exhibits unique properties. | |

| After performing various load tests on the new composite material, Teo and his colleagues expect the viscoelastic properties of the nanomattress to be largely dependent on the density of the CNTs within the film as well as on their physical dimensions and type (single vs. multi-walled). | |

| "With fewer CNTs to support the top film, the composite materials would likely be easier to compress compared to a higher density material" says Teo. "Physical dimensions such as length and width would have a direct influence on the stiffness of the CNTs and, therefore, the amount of energy needed to bend them. Hence, it should be possible to grow composite films with various damping and shock-absorbing properties that can be controlled by the dimensions of the CNTs, area density, and the overgrown a-D layer." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|