| Posted: Nov 18, 2011 | |

Non-toxic, solution-based inorganic solar cell chemistry with Earth-abundant elements |

|

| (Nanowerk Spotlight) While the current solar panel market (18.2 GWp manufactured in 2010) is still dominated by crystalline silicon solar cells, thin-film solar cell technologies based on chalcogenides (S, Se, and Te) are dramatically increasing their market penetration. For instance, the company First Solar produced 1.5 GW of CdTe modules in 2010 with an estimated 2.3 GW by the end of 2011. Other CdTe companies like Primestar (owned by energy giant GE) are ramping up CdTe production while a sea of other companies (Solar Frontier, Miasole, Ascent, Nanosolar, etc.) are focusing on CIGS (copper indium gallium (di)selenide) solar cells. CIGS holds the possibility for higher efficiencies with lab scale device efficiencies already at 20.3% ("New world record efficiency for Cu(In,Ga)Se2 thin-film solar cells beyond 20%"). | |

| Apart from device performance, price volatility issues (in particular with indium), rare earth elements scarcity issues (for instance with tellurium), and potential environmental issues (e.g. toxicity issues with cadmium) have raised some concerns about both CdTe and CIGS. A frontrunner in the search for the next generation of thin film photovoltaic materials are low-cost quaternary copper-zinc-tin-sulfide (CZTS) and copper-zinc-tin-chalcogenide (CZTSSe). Notably, these materials are composed of naturally abundant elements in the Earth's crust and have very low toxicity (see "Abundant inorganic material could replace platinum in dye-sensitized solar cells"). | |

| "Historically, most CZTS thin film solar cells synthesized were obtained from vacuum deposition of metal precursors followed by sulfurization," Hugh W. Hillhouse, Rehnberg Chair Professor in the Department of Chemical Engineering at the University of Washington, explains to Nanowerk. "However, such methods are challenging because of cost, spatial heterogeneity of composition and the formation of binary compounds such as ZnS. For this reason, several solution-based inorganic solar cell chemistries are being developed in an effort to significantly reduce manufacturing cost and improve performance." | |

| The current record CZTSSe solar cell, with over 10.1% power conversion efficiency, fabricated by Mitzi and colleagues at IBM ("High-Efficiency Solar Cell with Earth-Abundant Liquid-Processed Absorber"), is made using precursors stabilized in hydrazine – a hepatotoxic, explosive and carcinogenic solvent. | |

| In a paper in a recent issue of Advanced Energy Materials ("Earth-Abundant Element Photovoltaics Directly from Soluble Precursors with High Yield Using a Non-Toxic Solvent"), Hillhouse and his team show that there are other chemical routes that use much more benign solvents by demonstrating a simple and facile solution phase method to form CZTS thin film solar cell using commercially available precursors and non-toxic solvents with high yield. | |

| A key finding in this work is that there are alternatives to using nanocrystal inks or using toxic solvents like hydrazine that can yield efficient solution processed solar cells. | |

| "In fact, we are probably just scratching the surface of what is possible with regard to inorganic solar cells from solution processing" says Hillhouse. | |

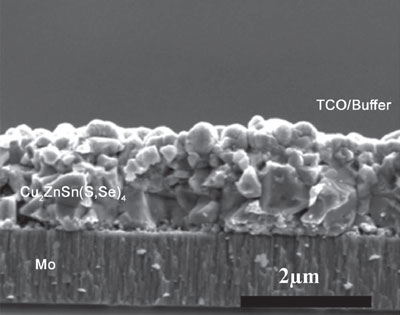

| His facile new chemical route to CZTSSe thin film solar cells is based on spin-coating a solution of highly soluble, inexpensive, and commercially available precursors in an environmentally friendly non-toxic solvent (i.e. dimethyl sulfoxide) to form device quality CZTS films on molybdenum coated sodalime glass followed by selenization. The completed solar cell device, which is air-stable, showed an efficiency of 4.1%. | |

|

|

| A cross sectional SEM image of CZTSSe photovoltaic devices. The CZTSSe film shows large crystalline grain and some voids. (Reprinted with permission from Wiley-VCH Verlag) | |

| Hillhouse points out that the yield of metal incorporation – from precursor to film – approaches 100% in this method, which is not the case with nanocrystal-ink routes that have yielded 7.2% efficient devices. | |

| This novel processing route could open the door to the low-cost, solution processed fabrication of thin-film solar cells based on Earth abundant elements. The absorber layer could be deposited by slot die coating, curtain coating, or other easily scalable processes. | |

| "So far, very little is known about the fundamental electronic properties, defect physics, thermodynamics, or formation kinetics of CZTS, and even less is known about heterojunction photovoltaic devices based on CZTS," says Hillhouse. "The theoretical efficiency limit for a single junction solar cell using CZTS or CZTSe are both over 30%. It is possible that, once some of these fundamentals are in place, solar cells based on CZTS could one day supersede CIGS, CdTe, and even silicon based photovoltaic technology." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|