| Posted: Apr 03, 2014 | |

Interwoven solar cells turn T-shirt into a power textile |

|

| (Nanowerk Spotlight) Forget about Google Glass or the latest smart watch announcements – the future will belong to electronic textiles (e-textiles) that will allow the design and production of a new generation of garments with built-in unobtrusive sensors and a variety of electronic functions. Such e-textiles will have the revolutionary ability to sense, act, store, emit, and move – think biomedical monitoring functions or new man-machine interfaces – while ideally leveraging an existing low-cost textile manufacturing infrastructure. | |

| All these wearable and potentially textile-embedded electronic gadgets will require power; and it wouldn't make sense to have to plug your sleek flexible sleeve display into a bulky lithium-ion battery brick. In a previous Nanowerk Spotlight we reported on wearable energy storage ("Nanotechnology T-shirt to replace batteries? Towards wearable energy storage"). Today, we look at recent developments that would actually allow your T-shirt to generate power from its interwoven solar cell wires. | |

| Reporting their results in the March 27, 2014 online edition of Advanced Energy Materials ("Weaving Efficient Polymer Solar Cell Wires into Flexible Power Textiles"), researchers in China have developed a novel efficient wire-shaped polymer solar cell by incorporating a thin layer of titania nanoparticles between the photoactive material and electrode. | |

| The aligned carbon nanotube fiber enabled high flexibility and stability of the resulting polymer solar cell. These miniature polymer solar cell wires, when woven into textiles, can serve as a power source. | |

| "We found that the titania nanoparticle enhance the adsorption of photoactive materials and charge transport, which increased the energy conversion efficiency by 36% compared with the wire-shaped polymer solar cell without the titania nanoparticle under the same condition," Zhitao Zhang, a student in Prof. Huisheng Peng's research group in the Department of Macromolecular Science at Fudan University, and first author of the paper, tells Nanowerk. | |

|

|

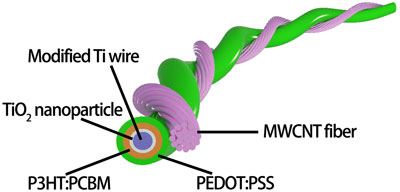

| Schematic illustration of the wire-shaped polymer solar cell. (Image: Peng Group, Fudan University) | |

| The above image schematically shows the structure of the wire-shaped polymer solar cell (PSC) with a titanium (Ti) wire and an aligned multiwalled carbon nanotube (MWCNT) fiber as cathode and anode, respectively. In a typical fabrication, a Ti wire was modified by growing aligned titania nanotubes on the surface by electrochemical anodization, followed by coating of a layer of titania nanoparticles. Two polymer layers were then dip-coated onto the modified Ti wire. The resulting Ti wire was finally wound with an aligned MWCNT fiber to produce the wire-shaped polymer solar cell. | |

| According to the researchers, the nanocrystalline semiconductor oxide layer played a crucial role in providing pathways for charge transport. Here the incorporation of semiconducting nanoparticles at the tips of aligned TiO2 nanotubes after TiCl4 treatment helped to make the outer surface uniform. | |

| In addition, the nanoparticle layer effectively increases the polymer load, decreases the electrical resistance for charge transport, and enhances light scattering. | |

| "We found that the diameters of MWCNT fibers affect the wire-shaped PSCs to a large degree, " explains Zhang. "The energy conversion efficiencies were increased from 0.72% to 1.78% with the increasing diameters from 18 to 32 µm and then decreased with the further increasing diameters (e.g., 1.47% and 1.18% at 60 and 74 µm, respectively)." | |

| The maximal efficiency occurred at approximately 32 µm. | |

| "A smaller fiber produced a higher electric resistance with a lower current density, while a bigger fiber shaded the incident sunlight also to decrease the current density," says Zhang. | |

|

|

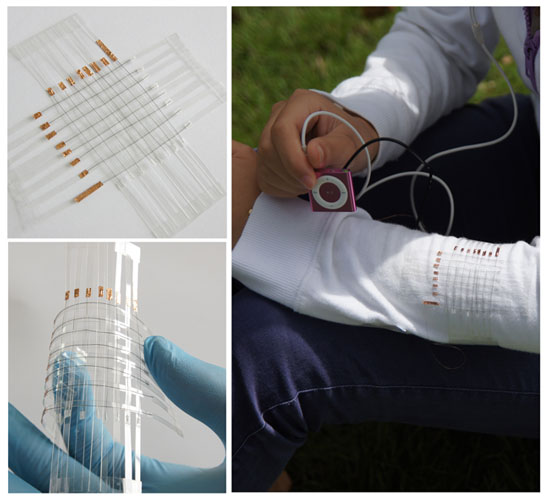

| Left top and bottom: The PSC textile being bent into different structures. Right: The PSC woven into a shirt powers an iPod Nano. (Reprinted with permission from Wiley-VCH Verlag) | |

| The team tested the wire-shaped PSCs for flexibility and bendability and, even after 1000 bending cycles, found no obvious damages or decreased energy conversion efficiencies. | |

| The as-prepared wire-shaped PSC could be easily woven into various flexible structures such as textiles without the necessity for sealing that had been required by the widely studied wire-shaped dye-sensitized solar cells. | |

| Going forward, the researchers will work on increasing the performance of their wire-shaped polymer solar cells and also, in addition to bendability, make them stretchable. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|