| Posted: Dec 02, 2014 | |

Superstable copper nanowire stretchable conductors |

|

| (Nanowerk Spotlight) Most printed electronics applications rely on some kind of ink formulated with conductive materials. Silver nanowires, due to their superior conductivity and intrinsic flexibility, have become a popular choice for fabricating the required flexible and stretchable electrodes (read more: "Conductive nanomaterials for printed electronics applications"). | |

| The use of copper – which is much cheaper and more abundant – as an alternative electrode material to silver would dramatically reduce the cost of these nanowire materials. Despite these advantages, copper nanowire conductors face a serious bottleneck for future practical use in flexible and stretchable optoelectronics: although they are nearly as conductive as silver, this conductivity is not stable. | |

| Researchers have now demonstrated conductive copper nanowire elastomer composites with ultrahigh performance stability against oxidation, bending, stretching, and twisting. This material offers a promising alternative as electrodes for flexible and stretchable optoelectronics. | |

| "In contrast to the previously suggested two-step method, we first developed a scalable one-pot method to synthesize highly stable, conductive copper nanowires with Cu4Ni alloying shells," Professor Haibo Zeng, Director of the Institute of Optoelectronics & Nanomaterials at Nanjing University of Science and Technology, tells Nanowerk. "Profiting from such consecutive growth and in situ surface alloying, the highly crystalline alloyed shells, clear and abrupt interfaces, a length more than 50 µm, and smooth surfaces have been achieved to favor their stability." | |

| Zeng and his team have reported their findings in Nano Letters("Superstable Transparent Conductive Cu@Cu4Ni Nanowire Elastomer Composites against Oxidation, Bending, Stretching, and Twisting for Flexible and Stretchable Optoelectronics") | |

|

|

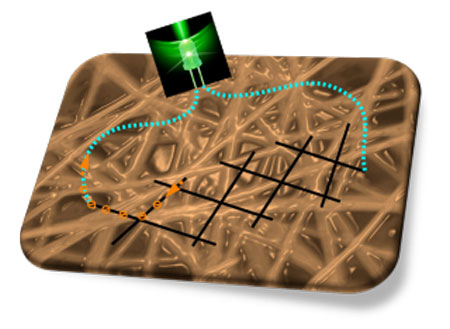

| Copper nanowire network transparent electrodes for optoelectronics. (Image: Institute of Optoelectronics & Nanomaterials, Nanjing University of Science and Technology) | |

| The performance characteristics of these nanowire-elastomer composites, with a low resistance of 62.4 ohm/sq at 80% transparency, is even better than the commercially used ITO/PET flexible electrodes. | |

| Furthermore, compared with pure copper nanowires, the researchers estimate the actual lifetime of their Cu@Cu4Ni nanowire electrodes to be more than 1,200 days. | |

| "This is the longest stable duration reported for copper nanowire based electrodes up to now and meets the demands for various flexible devices," says Jizhong Song, the paper's first author. "Neither the conductivity nor the performances of OLEDs with these copper nanowire elastomers as conductive circuits show evident degradation during 600 cycles of bending, stretching and twisting tests." | |

| In order to use these copper nanowires as transparent conductive electrodes for flexible and stretchable optoelectronics in practical applications, the main challenge will be to make them compatible with current industrial solution-based processes, such as roll-to-roll, blade coating production. According to the scientists, this could be solved by optimizing the viscosity and surface tension of the nanowire inks. | |

| Jianhai Li, a co-author of the paper, also points out that, besides the application of solution-based, flexible and stretchable organic light-emitting diodes (OLEDs) and solar cells, the highly stable, conductive Cu@Cu-Ni nanowire elastomer composites have a huge potential in other fields such as wearable electronics, robotic skins, implantable medical devices, and smart electrochromic windows. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|