| Posted: Oct 14, 2008 | |

Low-cost nanotechnology substitute for gold and silver in printable electronics |

|

| (Nanowerk Spotlight) Ink-jet printing of metal nanoparticles for conductive metal patterns has attracted great interest as an alternative to expensive fabrication techniques like vapor deposition. The bulk of the research in this area focuses on printing metal nanoparticle suspensions for metallization. For example, silver and gold nanoparticle suspensions have been inkjet printed to build active microelectromechanical systems (MEMS), flexible conductors and radio frequency identification (RFID) tags. Nobel metals like silver and gold are preferred nanoparticles for ink-jet formulations because they are good electrical conductors and they do not cause oxidation problems. However, gold and silver still are too expensive for most high volume, ultra low-cost applications such as RFID tags with required unit costs below one cent. | |

| In order to print metals one needs to prepare a metal ink, or, in terms of materials engineering, it requires matching the properties of small metal particles with an ink-jet base fluid. Furthermore, for large-scale and low-cost industrial applications, the ink needs to be rugged and stable against air and humidity. | |

| Although copper would be an obvious choice to replace gold and silver, like other non-noble metal nanoparticles it tends to oxidize spontaneously when in contact with ambient air. A new technique developed in Switzerland uses flame spray synthesis in combination with a simple in-situ functionalization step to synthesize graphene coated copper nanoparticles which are air-stable and can be easily handled at ambient conditions. | |

| This work illustrates graphene's potential as a protective shell material for nanoparticles, enabling control and design of the chemical reactivity of non-noble metals. | |

| "We have demonstrated that copper as a low-cost non-noble metal can resist oxidation under ambient conditions if coated by graphene bi- or tri-layers," Norman Lüchinger tells Nanowerk. | |

| Lüchinger, a PhD student in Wendelin Stark's Functional Materials Laboratory at ETH Zürich in Switzerland, is first author of a recent paper in Nanotechnology ("Graphene-stabilized copper nanoparticles as an air-stable substitute for silver and gold in low-cost ink-jet printable electronics") that describes the suitability of graphene coating for the broader use of non-noble metal nanoparticles. According to the scientists in Zürich, carbon coatings offer an economically attractive route to the broader use of metal nanoparticles for ambient conditions. | |

|

|

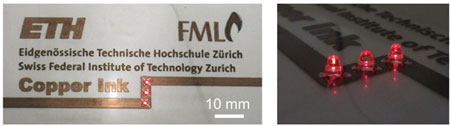

| Light-emitting diodes directly glued onto lines printed with ink made from graphene-stabilized copper nanoparticles. (Reprinted with permission from IOP Publishing) | |

| "Our present example using copper as a substitute for silver or gold ink-jet printing demonstrates a first step in the development of commodity metal nanoparticle applications" explains Stark. "Though currently inferior to the conductivity of printed gold or silver, the direct one-step synthesis of our carbon-coated copper particles and the use of well-established ink chemistry allowed us to use the metal ink in off-the-shelf ink-jet printers. This makes metal printing available to virtually any laboratory without the need for special equipment." | |

| The scientists point out that controlling the oxidation and corrosion of the technically most important non-noble metals through the controlled deposition of graphene coatings will enable a much broader use of common transition group metals in the form of nanomaterials. | |

| Potential applications for instance include RFID tags which have to be ultra-low cost for a broad application in industrial and consumer applications. | |

| The copper metal dispersions synthesized in Stark's group are deep black, stable for several weeks and have a viscosity similar to classical ink-jet formulations. They can be directly filled into a commercial ink-jet printer?s cartridge and processed using a standard low-cost ink-jet printer. | |

| One issue that needs to be improved is the conductivity of the printed lines, which needs to be increased to become competitive with the conductivities of gold and silver. | |

| "The current non-optimized patterns have a relatively low, but sufficiently high, electrical conductivity to operate light-emitting diodes that were directly put onto the copper lines printed on a flexible polymer foil substrate" says Lüchinger. "Once we have sufficiently improved the conductivity, basically any application is imaginable where cost is a factor." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.