Showing Spotlights 1777 - 1784 of 2777 in category All (newest first):

Australian researchers have introduced the Nanopatch - a new way of delivering vaccines to the skin and potentially a safer, cheaper alternative to traditional needle vaccines. The Nanopatch comprises arrays of densely packed projections with a defined geometry and distribution designed to physically target vaccines directly to thousands of epidermal and dermal antigen presenting cells. These miniaturized arrays are two orders of magnitude smaller than standard needles and are also much smaller than current microneedle arrays. The core idea is to achieve improved vaccine efficiency and effectiveness - over the needle and syringe - through precise targeting of vaccines to skin strata, achieved by device miniaturization utilizing micro- and nanotechnologies.

Australian researchers have introduced the Nanopatch - a new way of delivering vaccines to the skin and potentially a safer, cheaper alternative to traditional needle vaccines. The Nanopatch comprises arrays of densely packed projections with a defined geometry and distribution designed to physically target vaccines directly to thousands of epidermal and dermal antigen presenting cells. These miniaturized arrays are two orders of magnitude smaller than standard needles and are also much smaller than current microneedle arrays. The core idea is to achieve improved vaccine efficiency and effectiveness - over the needle and syringe - through precise targeting of vaccines to skin strata, achieved by device miniaturization utilizing micro- and nanotechnologies.

Aug 31st, 2010

Improvements in the design of medical equipment for better streamlined functionality and performance is influenced by a number of critical factors. The research, design, modeling, testing, prototyping, and FDA and EU approvals of new mechatronic devices, or the integration of changes to existing designs, usually represents a sizable capital investment of resources well before the equipment goes into serial production. Factored into the medical device's product development are considerations such as size of the equipment, speed of operation, heat generation, portability, handling of static or kinetic loads, power sources, measuring systems, vacuum and nonmagnetic requirements, sensors, machine controls, component part wear and diagnostics. A key impetus for medical and bioresearch companies to engage upon these involved product development cycles is the opportunity to capitalize on advances in technology for the manufacture of better operating, lower cost and more efficient equipment and devices.

Improvements in the design of medical equipment for better streamlined functionality and performance is influenced by a number of critical factors. The research, design, modeling, testing, prototyping, and FDA and EU approvals of new mechatronic devices, or the integration of changes to existing designs, usually represents a sizable capital investment of resources well before the equipment goes into serial production. Factored into the medical device's product development are considerations such as size of the equipment, speed of operation, heat generation, portability, handling of static or kinetic loads, power sources, measuring systems, vacuum and nonmagnetic requirements, sensors, machine controls, component part wear and diagnostics. A key impetus for medical and bioresearch companies to engage upon these involved product development cycles is the opportunity to capitalize on advances in technology for the manufacture of better operating, lower cost and more efficient equipment and devices.

Aug 27th, 2010

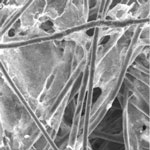

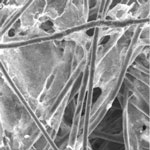

Various nanotechnologies are being researched for applications in water treatment because the removal of bacteria and other organisms from water is an extremely important process, not only for drinking and sanitation but also industrially as biofouling is a commonplace and serious problem. In what could be developed as a a cheap point-of-use water filter for deactivating pathogens in water, or as a new component to be integrated into existing filtration systems to kill microorganisms which cause biofouling in downstream filters, researchers have now demonstrated a textile based device for the high speed electrical sterilization of water. They came up with a new strategy for taking advantage of silver nanowires' and carbon nanotubes' unique ability to form complex multiscale coatings on cotton to produce an electrically conducting and high surface area device for the active, high-throughput inactivation of bacteria in water.

Various nanotechnologies are being researched for applications in water treatment because the removal of bacteria and other organisms from water is an extremely important process, not only for drinking and sanitation but also industrially as biofouling is a commonplace and serious problem. In what could be developed as a a cheap point-of-use water filter for deactivating pathogens in water, or as a new component to be integrated into existing filtration systems to kill microorganisms which cause biofouling in downstream filters, researchers have now demonstrated a textile based device for the high speed electrical sterilization of water. They came up with a new strategy for taking advantage of silver nanowires' and carbon nanotubes' unique ability to form complex multiscale coatings on cotton to produce an electrically conducting and high surface area device for the active, high-throughput inactivation of bacteria in water.

Aug 26th, 2010

Along with control of fire, iron smelting is one of the founding technological pillars of civilization. Industry has used the same basic process to make iron for over 3000 years. Yet, it is also one of the major global sources of greenhouse gas release. Iron, a basic commodity, is still produced by the greenhouse gas intensive reduction of iron oxide by carbon-coke and currently accounts for the release of one quarter of worldwide carbon dioxide emissions by industry. For instance, on average 1.9 tonnes of carbon dioxide are emitted for every tonne of steel produced. Due to a large share of coal in the energy mix of current production technology, the CO2 emissions are high. Through a new understanding of the chemistry of iron at high temperature, researchers have uncovered an effective new carbon-dioxide-free process to form iron.

Along with control of fire, iron smelting is one of the founding technological pillars of civilization. Industry has used the same basic process to make iron for over 3000 years. Yet, it is also one of the major global sources of greenhouse gas release. Iron, a basic commodity, is still produced by the greenhouse gas intensive reduction of iron oxide by carbon-coke and currently accounts for the release of one quarter of worldwide carbon dioxide emissions by industry. For instance, on average 1.9 tonnes of carbon dioxide are emitted for every tonne of steel produced. Due to a large share of coal in the energy mix of current production technology, the CO2 emissions are high. Through a new understanding of the chemistry of iron at high temperature, researchers have uncovered an effective new carbon-dioxide-free process to form iron.

Aug 25th, 2010

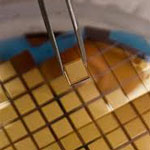

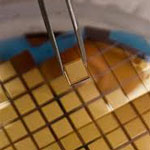

Most of today's lithium-ion batteries rely on anodes made from graphite, a form of carbon. There are several candidate electrodes to replace graphite as the anode for lithium-ion batteries. Such electrodes like silicon or tin have very high capacities but suffer from poor efficiency and cyclic stability as they experience large volume change and particle pulverization during repeated cycling. Silicon-based anodes, for instance, theoretically offer as much as a ten-fold capacity improvement over graphite, but silicon-based anodes have so far not been stable enough for practical use. Researchers have now used the macromolecular structure of self-assembled Tobacco mosaic virus as templates to fabricate stable three-dimensional current collectors for high power and high energy density Li-ion batteries.

Most of today's lithium-ion batteries rely on anodes made from graphite, a form of carbon. There are several candidate electrodes to replace graphite as the anode for lithium-ion batteries. Such electrodes like silicon or tin have very high capacities but suffer from poor efficiency and cyclic stability as they experience large volume change and particle pulverization during repeated cycling. Silicon-based anodes, for instance, theoretically offer as much as a ten-fold capacity improvement over graphite, but silicon-based anodes have so far not been stable enough for practical use. Researchers have now used the macromolecular structure of self-assembled Tobacco mosaic virus as templates to fabricate stable three-dimensional current collectors for high power and high energy density Li-ion batteries.

Aug 24th, 2010

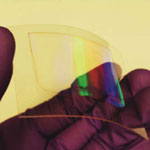

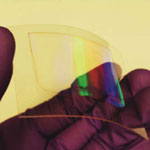

Molding - a manufacturing technique that dates back to the Bronze Age - also has found applications in nanofabrication techniques in the production of high-density optical and magnetic storage media, organic light-emitting diodes, polymer photovoltaic cells, and field-effect transistors. The basic idea of molding is to shape a pliable raw material such as plastic, glass or metal into a desired form by filling it into the mold. Whether it is on the macro- or nanoscale, most molding methods are limited to replicate the patterns that are identical to the original master. To pattern different structures, new masters are needed for every different structure. Researchers have now developed an all-moldable nanofabrication platform that can generate, from a single master, nanoscale patterns with programmable densities, fill factors, and lattice symmetries. They have named this technique solvent-assisted nanoscale embossing (SANE).

Molding - a manufacturing technique that dates back to the Bronze Age - also has found applications in nanofabrication techniques in the production of high-density optical and magnetic storage media, organic light-emitting diodes, polymer photovoltaic cells, and field-effect transistors. The basic idea of molding is to shape a pliable raw material such as plastic, glass or metal into a desired form by filling it into the mold. Whether it is on the macro- or nanoscale, most molding methods are limited to replicate the patterns that are identical to the original master. To pattern different structures, new masters are needed for every different structure. Researchers have now developed an all-moldable nanofabrication platform that can generate, from a single master, nanoscale patterns with programmable densities, fill factors, and lattice symmetries. They have named this technique solvent-assisted nanoscale embossing (SANE).

Aug 23rd, 2010

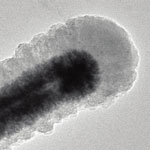

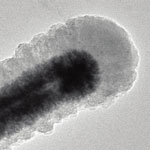

Supercapacitors, also called electric double layer capacitors (EDLC), store energy in two closely spaced layers with opposing charges and offer fast charge/discharge rates and the ability to sustain millions of cycles. It is frequently stated that supercapacitors bridge the gap between batteries and electrolytic ('conventional') capacitors, but contemporary devices have a lower specific energy than Li-ion batteries and are orders of magnitude slower than electrolytic capacitors. A research team has now shown that by moving from porous carbon with a network of pores inside particles as electrode material to exposed surfaces of nanostructured carbon onions of 6-7 nm diameter, it is possible to reach the discharge rate (power) of electrolytic capacitors, but with volumetric capacitance about four orders of magnitude higher. Moreover, observed discharge rates up to 200 V/second are about three orders of magnitude higher than conventional supercapacitors.

Supercapacitors, also called electric double layer capacitors (EDLC), store energy in two closely spaced layers with opposing charges and offer fast charge/discharge rates and the ability to sustain millions of cycles. It is frequently stated that supercapacitors bridge the gap between batteries and electrolytic ('conventional') capacitors, but contemporary devices have a lower specific energy than Li-ion batteries and are orders of magnitude slower than electrolytic capacitors. A research team has now shown that by moving from porous carbon with a network of pores inside particles as electrode material to exposed surfaces of nanostructured carbon onions of 6-7 nm diameter, it is possible to reach the discharge rate (power) of electrolytic capacitors, but with volumetric capacitance about four orders of magnitude higher. Moreover, observed discharge rates up to 200 V/second are about three orders of magnitude higher than conventional supercapacitors.

Aug 19th, 2010

Silver had already been recognized in ancient Greece and Rome for its infection-fighting properties but in modern times pharmaceutical companies made more money developing antibiotics. However, thanks to emerging nanotechnology applications, silver has made a comeback in the form of antimicrobial nanoparticle coatings for textiles, surgical instruments, lab equipment, floors or wall paints. The flip side of silver's desired toxicity towards microbes is that it might have toxic effects for humans as well and this has raised debate about the safety of nanosilver products. Although scientists have worked to reduce the toxicity of antimicrobial nanosilver in products, concerns remain. Not helping to put these concerns to rest is a new report from a group of researchers in Germany that shows that toxicity of silver nanoparticles increases during storage because of slow dissolution under release of silver ions.

Silver had already been recognized in ancient Greece and Rome for its infection-fighting properties but in modern times pharmaceutical companies made more money developing antibiotics. However, thanks to emerging nanotechnology applications, silver has made a comeback in the form of antimicrobial nanoparticle coatings for textiles, surgical instruments, lab equipment, floors or wall paints. The flip side of silver's desired toxicity towards microbes is that it might have toxic effects for humans as well and this has raised debate about the safety of nanosilver products. Although scientists have worked to reduce the toxicity of antimicrobial nanosilver in products, concerns remain. Not helping to put these concerns to rest is a new report from a group of researchers in Germany that shows that toxicity of silver nanoparticles increases during storage because of slow dissolution under release of silver ions.

Aug 18th, 2010

Australian researchers have introduced the Nanopatch - a new way of delivering vaccines to the skin and potentially a safer, cheaper alternative to traditional needle vaccines. The Nanopatch comprises arrays of densely packed projections with a defined geometry and distribution designed to physically target vaccines directly to thousands of epidermal and dermal antigen presenting cells. These miniaturized arrays are two orders of magnitude smaller than standard needles and are also much smaller than current microneedle arrays. The core idea is to achieve improved vaccine efficiency and effectiveness - over the needle and syringe - through precise targeting of vaccines to skin strata, achieved by device miniaturization utilizing micro- and nanotechnologies.

Australian researchers have introduced the Nanopatch - a new way of delivering vaccines to the skin and potentially a safer, cheaper alternative to traditional needle vaccines. The Nanopatch comprises arrays of densely packed projections with a defined geometry and distribution designed to physically target vaccines directly to thousands of epidermal and dermal antigen presenting cells. These miniaturized arrays are two orders of magnitude smaller than standard needles and are also much smaller than current microneedle arrays. The core idea is to achieve improved vaccine efficiency and effectiveness - over the needle and syringe - through precise targeting of vaccines to skin strata, achieved by device miniaturization utilizing micro- and nanotechnologies.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed