| Posted: Nov 10, 2015 | |

Spiders point the way to make better adhesives for high-humidity environments |

|

| (Nanowerk Spotlight) Scientists have long been fascinated by spider silk – a unique biopolymer that combines mechanical strength and elasticity to make it one of the toughest materials known. In addition, the silk threads are coated with an adhesive which ranks among the strongest biological glues. | |

| Spiders are one of the most diverse species on the planet. Currently, there are about 45,000 known species of spiders living in a variety of habitats and environments. About 1/6th of these species use webs to catch prey. | |

| The capture silk used in these webs consists of axial fiber coated with glue droplets at regular intervals. The spider glue has a unique property that its adhesion is humidity responsive such that for some species the adhesion keeps on increasing up to 100% relative humidity. | |

| This is unlike synthetic adhesives that fail under humid conditions. From a polymer science perspective, researchers are interested in understanding the principle behind humidity responsive adhesion of spider glue to create adhesives that work in high humidity conditions. | |

| "Adhesion in high humidity environment is a fundamental challenge for synthetic and natural adhesives; yet, some spider species that are active in highly humid environments use glue that is the stickiest in almost 100% humidity conditions," Ali Dhinojwala, H.A. Morton Professor in the Department of Polymer Science at the University of Akron, tells Nanowerk. "We find that the spider glue from five different species, living in diverse habitats, is maximally adhesive at the humidity where the spider hunts for prey. This is intuitive but beautiful to observe in data." | |

| Previously, Dhinojwala's group had worked on understanding the mechanism of spider glue adhesion at a particular humidity ("Ubiquitous distribution of salts and proteins in spider glue enhances spider silk adhesion"). | |

| A new paper just published in ACS Nano ("Spiders Tune Glue Viscosity to Maximize Adhesion") discusses the mechanism of humidity responsive adhesion of spider glue. | |

| "We observed that the glue extensibility increased dramatically with an increase in humidity," says Gaurav Amarpuri, a PhD student in Dhinojwala's group and the paper's first author. "We used high speed imaging to quantify the spreading of glue and further used spreading power law to measure the glue viscosity." | |

|

|

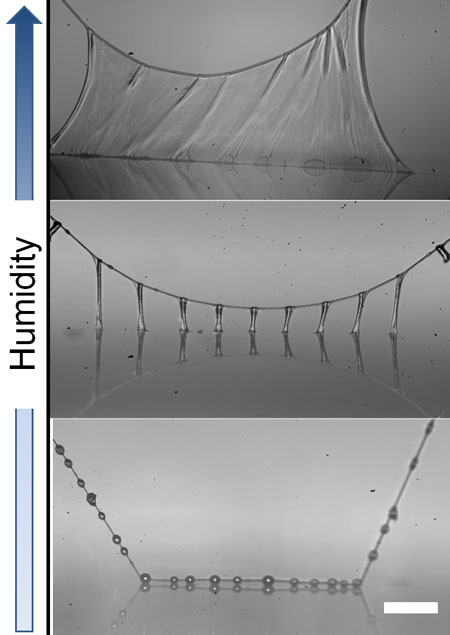

| Larinioides cornutus capture threads peeled from a glass substrate, under low, medium, and high humidity conditions. Note the increase in glue extensibility with humidity. At medium humidity, the glue droplets form a suspension bridge structure where adhesion is maximum. Scale bar is 100µm. (Image: Yizhou Chen, University of Akron) (click on image to enlarge) | |

| The scientists found that glue viscosity changes over five orders of magnitude with a change in humidity from 30%-90% relative humidity – no other system changes viscosity so dramatically with relative humidity. This change is similar to glue changing from the consistency of peanut butter to the consistency of olive oil. However, at the humidity of maximum adhesion, the glue of these five diverse species had very similar viscosity in the range of 105-106 cP (centipoise). | |

| "This shows that there exists an optimum viscosity of maximum adhesion, and different spider species tune their glue viscosity to achieve this maximum adhesion at very different humidities," Amarpuri points out. "We found that the spider glue adhesion was maximum at the humidity the spider glue is supposed to function. For example, the Argiope species is active during day in open fields, and its glue was stickiest at 30-50%, while the Tetragnatha species is active at night above streams of water, and its adhesion kept on increasing up to 100% relative humidity." | |

| This observation poses a lot of questions for the scientists – the most obvious one being: how do these different species modulate their glue adhesion performance? | |

| "Spider glue consists of proteins and salts," explains Dhinojwala. "Salts are low molecular weight organic compounds, which are hygroscopic. The interaction between salts and proteins causes the viscosity to change dramatically with humidity." | |

| "Investigating the protein structure of the capture glue in different spider species is challenging due to limitation in sample size and availability," he adds. "But the salts vary significantly in ratio and composition in species. We are currently trying to understand the role of salts and proteins in modulating viscosity and hence adhesion." | |

| This study highlights viscosity modulation as a potent tool that various organisms use to derive different functionalities. The mechanism of how spider species are able to adapt to their local environment and modulate viscosity will help in the development of next generation smart adhesives. | |

| Further efforts in quantification of bulk rheological changes in biological materials may result in a new class of smart materials. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|