Showing Spotlights 1793 - 1800 of 2790 in category All (newest first):

Along with control of fire, iron smelting is one of the founding technological pillars of civilization. Industry has used the same basic process to make iron for over 3000 years. Yet, it is also one of the major global sources of greenhouse gas release. Iron, a basic commodity, is still produced by the greenhouse gas intensive reduction of iron oxide by carbon-coke and currently accounts for the release of one quarter of worldwide carbon dioxide emissions by industry. For instance, on average 1.9 tonnes of carbon dioxide are emitted for every tonne of steel produced. Due to a large share of coal in the energy mix of current production technology, the CO2 emissions are high. Through a new understanding of the chemistry of iron at high temperature, researchers have uncovered an effective new carbon-dioxide-free process to form iron.

Along with control of fire, iron smelting is one of the founding technological pillars of civilization. Industry has used the same basic process to make iron for over 3000 years. Yet, it is also one of the major global sources of greenhouse gas release. Iron, a basic commodity, is still produced by the greenhouse gas intensive reduction of iron oxide by carbon-coke and currently accounts for the release of one quarter of worldwide carbon dioxide emissions by industry. For instance, on average 1.9 tonnes of carbon dioxide are emitted for every tonne of steel produced. Due to a large share of coal in the energy mix of current production technology, the CO2 emissions are high. Through a new understanding of the chemistry of iron at high temperature, researchers have uncovered an effective new carbon-dioxide-free process to form iron.

Aug 25th, 2010

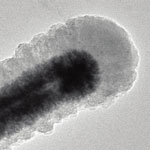

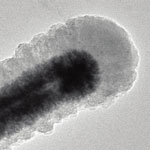

Most of today's lithium-ion batteries rely on anodes made from graphite, a form of carbon. There are several candidate electrodes to replace graphite as the anode for lithium-ion batteries. Such electrodes like silicon or tin have very high capacities but suffer from poor efficiency and cyclic stability as they experience large volume change and particle pulverization during repeated cycling. Silicon-based anodes, for instance, theoretically offer as much as a ten-fold capacity improvement over graphite, but silicon-based anodes have so far not been stable enough for practical use. Researchers have now used the macromolecular structure of self-assembled Tobacco mosaic virus as templates to fabricate stable three-dimensional current collectors for high power and high energy density Li-ion batteries.

Most of today's lithium-ion batteries rely on anodes made from graphite, a form of carbon. There are several candidate electrodes to replace graphite as the anode for lithium-ion batteries. Such electrodes like silicon or tin have very high capacities but suffer from poor efficiency and cyclic stability as they experience large volume change and particle pulverization during repeated cycling. Silicon-based anodes, for instance, theoretically offer as much as a ten-fold capacity improvement over graphite, but silicon-based anodes have so far not been stable enough for practical use. Researchers have now used the macromolecular structure of self-assembled Tobacco mosaic virus as templates to fabricate stable three-dimensional current collectors for high power and high energy density Li-ion batteries.

Aug 24th, 2010

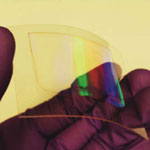

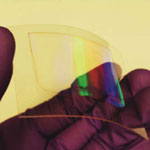

Molding - a manufacturing technique that dates back to the Bronze Age - also has found applications in nanofabrication techniques in the production of high-density optical and magnetic storage media, organic light-emitting diodes, polymer photovoltaic cells, and field-effect transistors. The basic idea of molding is to shape a pliable raw material such as plastic, glass or metal into a desired form by filling it into the mold. Whether it is on the macro- or nanoscale, most molding methods are limited to replicate the patterns that are identical to the original master. To pattern different structures, new masters are needed for every different structure. Researchers have now developed an all-moldable nanofabrication platform that can generate, from a single master, nanoscale patterns with programmable densities, fill factors, and lattice symmetries. They have named this technique solvent-assisted nanoscale embossing (SANE).

Molding - a manufacturing technique that dates back to the Bronze Age - also has found applications in nanofabrication techniques in the production of high-density optical and magnetic storage media, organic light-emitting diodes, polymer photovoltaic cells, and field-effect transistors. The basic idea of molding is to shape a pliable raw material such as plastic, glass or metal into a desired form by filling it into the mold. Whether it is on the macro- or nanoscale, most molding methods are limited to replicate the patterns that are identical to the original master. To pattern different structures, new masters are needed for every different structure. Researchers have now developed an all-moldable nanofabrication platform that can generate, from a single master, nanoscale patterns with programmable densities, fill factors, and lattice symmetries. They have named this technique solvent-assisted nanoscale embossing (SANE).

Aug 23rd, 2010

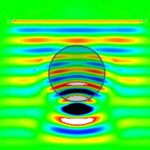

Supercapacitors, also called electric double layer capacitors (EDLC), store energy in two closely spaced layers with opposing charges and offer fast charge/discharge rates and the ability to sustain millions of cycles. It is frequently stated that supercapacitors bridge the gap between batteries and electrolytic ('conventional') capacitors, but contemporary devices have a lower specific energy than Li-ion batteries and are orders of magnitude slower than electrolytic capacitors. A research team has now shown that by moving from porous carbon with a network of pores inside particles as electrode material to exposed surfaces of nanostructured carbon onions of 6-7 nm diameter, it is possible to reach the discharge rate (power) of electrolytic capacitors, but with volumetric capacitance about four orders of magnitude higher. Moreover, observed discharge rates up to 200 V/second are about three orders of magnitude higher than conventional supercapacitors.

Supercapacitors, also called electric double layer capacitors (EDLC), store energy in two closely spaced layers with opposing charges and offer fast charge/discharge rates and the ability to sustain millions of cycles. It is frequently stated that supercapacitors bridge the gap between batteries and electrolytic ('conventional') capacitors, but contemporary devices have a lower specific energy than Li-ion batteries and are orders of magnitude slower than electrolytic capacitors. A research team has now shown that by moving from porous carbon with a network of pores inside particles as electrode material to exposed surfaces of nanostructured carbon onions of 6-7 nm diameter, it is possible to reach the discharge rate (power) of electrolytic capacitors, but with volumetric capacitance about four orders of magnitude higher. Moreover, observed discharge rates up to 200 V/second are about three orders of magnitude higher than conventional supercapacitors.

Aug 19th, 2010

Silver had already been recognized in ancient Greece and Rome for its infection-fighting properties but in modern times pharmaceutical companies made more money developing antibiotics. However, thanks to emerging nanotechnology applications, silver has made a comeback in the form of antimicrobial nanoparticle coatings for textiles, surgical instruments, lab equipment, floors or wall paints. The flip side of silver's desired toxicity towards microbes is that it might have toxic effects for humans as well and this has raised debate about the safety of nanosilver products. Although scientists have worked to reduce the toxicity of antimicrobial nanosilver in products, concerns remain. Not helping to put these concerns to rest is a new report from a group of researchers in Germany that shows that toxicity of silver nanoparticles increases during storage because of slow dissolution under release of silver ions.

Silver had already been recognized in ancient Greece and Rome for its infection-fighting properties but in modern times pharmaceutical companies made more money developing antibiotics. However, thanks to emerging nanotechnology applications, silver has made a comeback in the form of antimicrobial nanoparticle coatings for textiles, surgical instruments, lab equipment, floors or wall paints. The flip side of silver's desired toxicity towards microbes is that it might have toxic effects for humans as well and this has raised debate about the safety of nanosilver products. Although scientists have worked to reduce the toxicity of antimicrobial nanosilver in products, concerns remain. Not helping to put these concerns to rest is a new report from a group of researchers in Germany that shows that toxicity of silver nanoparticles increases during storage because of slow dissolution under release of silver ions.

Aug 18th, 2010

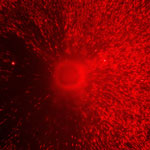

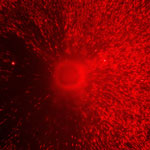

Nanotechnology-enabled tissue engineering is a rapidly growing field. At the core of tissue engineering is the construction of scaffolds out of biomaterials to provide mechanical support and guide cell growth into new tissues or organs. In particular, electrospun biodegradable polymeric nanofibers are being used in scaffolds for engineering various tissues such as nerves, cartilages or bone. Electrospinning is a fabrication technique which can produce nanoscale fibers from more than 100 different polymers. The electrospun nanofibers are typically collected as nonwoven mats with random orientation. A new study has now demonstrated the fabrication of a novel class of nanofiber scaffold composed of radially-aligned, electrospun nanofibers and also demonstrated the unique application of these materials as effective biomedical patches/scaffolds that could prove to be beneficial during neurosurgery.

Nanotechnology-enabled tissue engineering is a rapidly growing field. At the core of tissue engineering is the construction of scaffolds out of biomaterials to provide mechanical support and guide cell growth into new tissues or organs. In particular, electrospun biodegradable polymeric nanofibers are being used in scaffolds for engineering various tissues such as nerves, cartilages or bone. Electrospinning is a fabrication technique which can produce nanoscale fibers from more than 100 different polymers. The electrospun nanofibers are typically collected as nonwoven mats with random orientation. A new study has now demonstrated the fabrication of a novel class of nanofiber scaffold composed of radially-aligned, electrospun nanofibers and also demonstrated the unique application of these materials as effective biomedical patches/scaffolds that could prove to be beneficial during neurosurgery.

Aug 17th, 2010

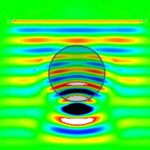

A problem with conventional photolithography techniques is that they cannot achieve the small size requirement of nanoholes and nanopillars, required for various nanofabrication applications, because of the wavelength limitation of the exposure light source. Other nanolithography techniques, such as electron-beam lithography, focused ion beam milling, and x-ray lithography, have the high resolution to form these nanoholes and nanopillars. However, these techniques are all very expensive or have too low a throughput to fabricate a large area of repetitive nanopatterns. A low cost nanosphere lithography method for patterning and generation of semiconductor nanostructures provides a potential alternative to conventional top-down fabrication techniques.

A problem with conventional photolithography techniques is that they cannot achieve the small size requirement of nanoholes and nanopillars, required for various nanofabrication applications, because of the wavelength limitation of the exposure light source. Other nanolithography techniques, such as electron-beam lithography, focused ion beam milling, and x-ray lithography, have the high resolution to form these nanoholes and nanopillars. However, these techniques are all very expensive or have too low a throughput to fabricate a large area of repetitive nanopatterns. A low cost nanosphere lithography method for patterning and generation of semiconductor nanostructures provides a potential alternative to conventional top-down fabrication techniques.

Aug 16th, 2010

Spin coating has been the dominant fabrication method for polymer electronics. However, it is not a high-throughput process and numerous research groups are trying to find a scalable fabrication method for polymer solar cells. One such method, spray coating, is capable of delivering large-area, uniform polymer thin films through a relatively simple process, while offering ample processing possibilities of engineering the film structure. Spray-coating is a high-rate, large-area deposition technique that ensures an ideal coating on a variety of surfaces with different morphologies and topographies. It is frequently used for industrial coating and in-line deposition processes. In spray-coating systems, the ink is atomized at the nozzle by pressure or ultrasound and then directed toward the substrate by a gas. An added advantage of spray-coating is that it is efficient: compared to other techniques only a small amount of the solutions are wasted.

Spin coating has been the dominant fabrication method for polymer electronics. However, it is not a high-throughput process and numerous research groups are trying to find a scalable fabrication method for polymer solar cells. One such method, spray coating, is capable of delivering large-area, uniform polymer thin films through a relatively simple process, while offering ample processing possibilities of engineering the film structure. Spray-coating is a high-rate, large-area deposition technique that ensures an ideal coating on a variety of surfaces with different morphologies and topographies. It is frequently used for industrial coating and in-line deposition processes. In spray-coating systems, the ink is atomized at the nozzle by pressure or ultrasound and then directed toward the substrate by a gas. An added advantage of spray-coating is that it is efficient: compared to other techniques only a small amount of the solutions are wasted.

Aug 13th, 2010

Along with control of fire, iron smelting is one of the founding technological pillars of civilization. Industry has used the same basic process to make iron for over 3000 years. Yet, it is also one of the major global sources of greenhouse gas release. Iron, a basic commodity, is still produced by the greenhouse gas intensive reduction of iron oxide by carbon-coke and currently accounts for the release of one quarter of worldwide carbon dioxide emissions by industry. For instance, on average 1.9 tonnes of carbon dioxide are emitted for every tonne of steel produced. Due to a large share of coal in the energy mix of current production technology, the CO2 emissions are high. Through a new understanding of the chemistry of iron at high temperature, researchers have uncovered an effective new carbon-dioxide-free process to form iron.

Along with control of fire, iron smelting is one of the founding technological pillars of civilization. Industry has used the same basic process to make iron for over 3000 years. Yet, it is also one of the major global sources of greenhouse gas release. Iron, a basic commodity, is still produced by the greenhouse gas intensive reduction of iron oxide by carbon-coke and currently accounts for the release of one quarter of worldwide carbon dioxide emissions by industry. For instance, on average 1.9 tonnes of carbon dioxide are emitted for every tonne of steel produced. Due to a large share of coal in the energy mix of current production technology, the CO2 emissions are high. Through a new understanding of the chemistry of iron at high temperature, researchers have uncovered an effective new carbon-dioxide-free process to form iron.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed