Showing Spotlights 2249 - 2256 of 2784 in category All (newest first):

The food industry is excited about the potential of nanotechnology. Food companies are very much involved in exploring and implementing nanotechnology applications in food processing, packaging and even growing - but you don't hear about it anymore. At least not from the companies. Large industrial food companies, no stranger to big and expensive media campaigns, have buried the subject of nanotechnology in their public relations graveyard. Take Kraft Foods for example. While it took the industry's nanotechnology lead when it established the Nanotek Consortium in 2000, it has since pulled back completely on the PR front. The Nanotek Consortium even was renamed the 'Interdisciplinary Network of Emerging Science and Technologies' (INEST), is now sponsored by Altria, and its single webpage makes no mention of food at all. Doing our regular check on the websites of large food companies we again found not a single reference to 'nanotechnology' or even 'nano'. The same is true for large food industry associations such as the Grocery Manufacturers/Food Products Association (GMA/FPA), which represents the world's leading food, beverage and consumer products companies. Faced with a complete nanotechnology communications blackout from the manufacturers, it is left to activist groups like Friends of the Earth to frame the discussion. These groups are trying to figure out what the food industry is up to and if there might be any risks involved that we should know about.

The food industry is excited about the potential of nanotechnology. Food companies are very much involved in exploring and implementing nanotechnology applications in food processing, packaging and even growing - but you don't hear about it anymore. At least not from the companies. Large industrial food companies, no stranger to big and expensive media campaigns, have buried the subject of nanotechnology in their public relations graveyard. Take Kraft Foods for example. While it took the industry's nanotechnology lead when it established the Nanotek Consortium in 2000, it has since pulled back completely on the PR front. The Nanotek Consortium even was renamed the 'Interdisciplinary Network of Emerging Science and Technologies' (INEST), is now sponsored by Altria, and its single webpage makes no mention of food at all. Doing our regular check on the websites of large food companies we again found not a single reference to 'nanotechnology' or even 'nano'. The same is true for large food industry associations such as the Grocery Manufacturers/Food Products Association (GMA/FPA), which represents the world's leading food, beverage and consumer products companies. Faced with a complete nanotechnology communications blackout from the manufacturers, it is left to activist groups like Friends of the Earth to frame the discussion. These groups are trying to figure out what the food industry is up to and if there might be any risks involved that we should know about.

Apr 16th, 2008

There are several touch sensor technologies available to power touch screens like the ones you can find on your bank ATM, airport check-in kiosk or other self-service terminals. What they all have in common is that they are sensitive to human touch because their screens are coated with a special transparent thin film that act as a sensor. This sensor generally has an electrical current or signal going through it and touching the screen causes a voltage or signal change. Apart from touch screens, transparent conductive thin films are used in numerous products such as flat-panel displays, solar cells or as thermal barriers in energy-saving windows. Future applications will include flexible displays for e-papers, smart cards, 'heads-up' displays integrated into cockpit and car windows, and windows that can be used as a light source at night. All this has driven increased research activity in finding alternative novel transparent electrode materials with good stability, high transparency and excellent conductivity. Graphene is one good candidate and films based on carbon nanotubes have attracted significant attention recently as well. Researchers now have demonstrated the use of metallic nanotubes to make thin films that are semitransparent, highly conductive, flexible and come in a variety of colors.

There are several touch sensor technologies available to power touch screens like the ones you can find on your bank ATM, airport check-in kiosk or other self-service terminals. What they all have in common is that they are sensitive to human touch because their screens are coated with a special transparent thin film that act as a sensor. This sensor generally has an electrical current or signal going through it and touching the screen causes a voltage or signal change. Apart from touch screens, transparent conductive thin films are used in numerous products such as flat-panel displays, solar cells or as thermal barriers in energy-saving windows. Future applications will include flexible displays for e-papers, smart cards, 'heads-up' displays integrated into cockpit and car windows, and windows that can be used as a light source at night. All this has driven increased research activity in finding alternative novel transparent electrode materials with good stability, high transparency and excellent conductivity. Graphene is one good candidate and films based on carbon nanotubes have attracted significant attention recently as well. Researchers now have demonstrated the use of metallic nanotubes to make thin films that are semitransparent, highly conductive, flexible and come in a variety of colors.

Apr 15th, 2008

Self-assembly and self-organization are terms used to describe processes in which a disordered system of pre-existing components forms an organized structure or pattern as a consequence of specific, local interactions among the components themselves, without external direction. Self-organizing processes are common throughout nature and involve components from the molecular (e.g. protein folding) to the planetary scale (e.g. weather systems) and even beyond (e.g. galaxies). Self-assembly has become an especially important concept in nanotechnology. As miniaturization reaches the nanoscale, conventional manufacturing technologies fail because it has not been possible (yet) to build machinery that assembles nanoscale components into functional devices. Until robotic assemblers capable of nanofabrication can be built, self-assembly - together with chemical synthesis - will be the necessary technology to develop for bottom-up fabrication. The key to using self-assembly as a controlled and directed fabrication process lies in designing the components that are required to self-assemble into desired patterns and functions. Self-assembly reflects information coded - as shape, surface properties, charge, polarizability, magnetic dipole, mass, etc. - in individual components; these characteristics determine the interactions among them.

Self-assembly and self-organization are terms used to describe processes in which a disordered system of pre-existing components forms an organized structure or pattern as a consequence of specific, local interactions among the components themselves, without external direction. Self-organizing processes are common throughout nature and involve components from the molecular (e.g. protein folding) to the planetary scale (e.g. weather systems) and even beyond (e.g. galaxies). Self-assembly has become an especially important concept in nanotechnology. As miniaturization reaches the nanoscale, conventional manufacturing technologies fail because it has not been possible (yet) to build machinery that assembles nanoscale components into functional devices. Until robotic assemblers capable of nanofabrication can be built, self-assembly - together with chemical synthesis - will be the necessary technology to develop for bottom-up fabrication. The key to using self-assembly as a controlled and directed fabrication process lies in designing the components that are required to self-assemble into desired patterns and functions. Self-assembly reflects information coded - as shape, surface properties, charge, polarizability, magnetic dipole, mass, etc. - in individual components; these characteristics determine the interactions among them.

Apr 14th, 2008

Alzheimer's disease (AD), a brain disorder named for German physician Alois Alzheimer who first described it in 1906, is a disease that destroys brain cells, causing problems with memory, thinking and behavior. Alzheimer's gets worse over time, and it is fatal. It is also the most common form of dementia. The latest estimate is that 26.6 million people were suffering from Alzheimer's disease worldwide in 2006, and this number will rise to 100 million by 2050 - 1 in 85 of the total population. The latest 2008 data for the US alone estimates that 5 million Americans have the disease, with an estimated increase to 11 to 16 million by 2050. Not only does Alzheimer's have no cure, even its cause is unknown (research has led to several theories that are still being investigated). The onset of AD is usually very slow and gradual and, since there is no test for it, there is no clear-cut line between normal age-related changes and warning signs. An absolute diagnosis of AD can only be determined during the examination of brain tissue, which is usually done during an autopsy. A recent report provides an overview of the promises that nanotechnology brings in research on diagnosis and therapy of AD.

Alzheimer's disease (AD), a brain disorder named for German physician Alois Alzheimer who first described it in 1906, is a disease that destroys brain cells, causing problems with memory, thinking and behavior. Alzheimer's gets worse over time, and it is fatal. It is also the most common form of dementia. The latest estimate is that 26.6 million people were suffering from Alzheimer's disease worldwide in 2006, and this number will rise to 100 million by 2050 - 1 in 85 of the total population. The latest 2008 data for the US alone estimates that 5 million Americans have the disease, with an estimated increase to 11 to 16 million by 2050. Not only does Alzheimer's have no cure, even its cause is unknown (research has led to several theories that are still being investigated). The onset of AD is usually very slow and gradual and, since there is no test for it, there is no clear-cut line between normal age-related changes and warning signs. An absolute diagnosis of AD can only be determined during the examination of brain tissue, which is usually done during an autopsy. A recent report provides an overview of the promises that nanotechnology brings in research on diagnosis and therapy of AD.

Apr 11th, 2008

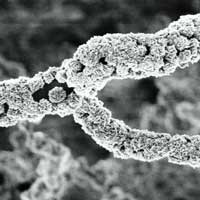

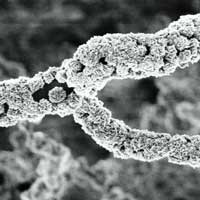

Despite their name, carbon nanotubes (CNTs) are not made of 100% carbon. Depending on which of the various synthesis techniques is used in their production, CNTs have variable chemistries and physical properties resulting from their different metal catalysts or amorphous carbon coatings. As a result, they may contain large percentages of metal and carbonaceous impurities which will have different environmental and toxicological impacts. In early toxicological studies, researchers obtained confounding results - in some studies nanotubes were toxic; in others, they were not. The apparent contradictions were actually a result of the materials that the researchers were using, not appreciating that 'carbon nanotubes' are really 'carbon nanotubes + metal + amorphous impurities'. Ignoring these impurities prohibits scientists from fully understanding the material's electronic character, environmental transport, transformation, and ecotoxicology. To address these needs, a group of researchers measured the elemental, molecular, and stable carbon isotope compositions of commercially available single-walled carbon nanotubes (SWCNTs) produced by ten companies in the United States, giving a true picture of their diversity and chemical complexity. This diversity and complexity is extremely important from both fate and toxicity perspectives.

Despite their name, carbon nanotubes (CNTs) are not made of 100% carbon. Depending on which of the various synthesis techniques is used in their production, CNTs have variable chemistries and physical properties resulting from their different metal catalysts or amorphous carbon coatings. As a result, they may contain large percentages of metal and carbonaceous impurities which will have different environmental and toxicological impacts. In early toxicological studies, researchers obtained confounding results - in some studies nanotubes were toxic; in others, they were not. The apparent contradictions were actually a result of the materials that the researchers were using, not appreciating that 'carbon nanotubes' are really 'carbon nanotubes + metal + amorphous impurities'. Ignoring these impurities prohibits scientists from fully understanding the material's electronic character, environmental transport, transformation, and ecotoxicology. To address these needs, a group of researchers measured the elemental, molecular, and stable carbon isotope compositions of commercially available single-walled carbon nanotubes (SWCNTs) produced by ten companies in the United States, giving a true picture of their diversity and chemical complexity. This diversity and complexity is extremely important from both fate and toxicity perspectives.

Apr 10th, 2008

Have you ever tried to peel a fresh tomato? Then you probably know that frustrating feeling when you end up with lots of little, mostly triangular pieces of skin. Of course you will also have remembered your grandma's trick to pour hot water over a tomato before skinning it; surprisingly, the skin then comes off easily in just a few large pieces. There are lots of other examples from our daily lives with similarly aggravating experiences: Frustrated by scotch tape that won't peel off the roll in a straight line? Angry at wallpaper that refuses to tear neatly off the wall? Cursing at the price sticker that doesn't come off in one piece? Or you dutifully follow the 'tear along the dotted line' instruction on a re-sealable bag only to be confronted with a tear that is anywhere but on the dotted line. Physicists, mathematicians and materials engineers love these things because it gives them a chance to explain everyday phenomena with impressive looking formulas and diagrams. Wrinkling, folding and crumpling of thin films have been characterized by experiments, theory and numerical simulations. A new study now adds a new element: fracture. The results suggest that the coupling between elasticity, adhesion and fracture, imprinted in a tear shape, can be used to evaluate mechanical properties of thin films and could even be applied at the nanoscale.

Have you ever tried to peel a fresh tomato? Then you probably know that frustrating feeling when you end up with lots of little, mostly triangular pieces of skin. Of course you will also have remembered your grandma's trick to pour hot water over a tomato before skinning it; surprisingly, the skin then comes off easily in just a few large pieces. There are lots of other examples from our daily lives with similarly aggravating experiences: Frustrated by scotch tape that won't peel off the roll in a straight line? Angry at wallpaper that refuses to tear neatly off the wall? Cursing at the price sticker that doesn't come off in one piece? Or you dutifully follow the 'tear along the dotted line' instruction on a re-sealable bag only to be confronted with a tear that is anywhere but on the dotted line. Physicists, mathematicians and materials engineers love these things because it gives them a chance to explain everyday phenomena with impressive looking formulas and diagrams. Wrinkling, folding and crumpling of thin films have been characterized by experiments, theory and numerical simulations. A new study now adds a new element: fracture. The results suggest that the coupling between elasticity, adhesion and fracture, imprinted in a tear shape, can be used to evaluate mechanical properties of thin films and could even be applied at the nanoscale.

Apr 9th, 2008

Diamonds have been known in India for at least 3000 years and are thought to have been first recognized and mined there. The most familiar usage of diamonds today is as gemstones in jewelry but, apart from being a girl's best friend, it seems that diamonds, especially nanodiamonds, are quickly becoming a scientist's best friend as well. Diamonds are the hardest natural material - the word diamond comes from the Greek term adamas, which means 'invincible' - has the lowest coefficient of thermal conductivity, is electrically insulating, chemically inert, and optically transparent. In nanoparticulate form, diamonds possess an additional property that makes them so interesting for researchers: since they are carbon-based and non-toxic they are a suitable material for drug delivery, drug diagnostics and medical imaging applications. One of the challenges in fabricating nanodiamond coatings and composite materials is the difficulty of controlling the size, texture, and crystalline quality of the diamond particles. Now, researchers in Portugal have demonstrated for the first time the facile fabrication and the conformal coating of nanocrystalline diamond onto silica nanofibers by a two-step method: synthesis of templates on silicon wafer; and coating of the silica fibers with nanocrystalline diamond.

Diamonds have been known in India for at least 3000 years and are thought to have been first recognized and mined there. The most familiar usage of diamonds today is as gemstones in jewelry but, apart from being a girl's best friend, it seems that diamonds, especially nanodiamonds, are quickly becoming a scientist's best friend as well. Diamonds are the hardest natural material - the word diamond comes from the Greek term adamas, which means 'invincible' - has the lowest coefficient of thermal conductivity, is electrically insulating, chemically inert, and optically transparent. In nanoparticulate form, diamonds possess an additional property that makes them so interesting for researchers: since they are carbon-based and non-toxic they are a suitable material for drug delivery, drug diagnostics and medical imaging applications. One of the challenges in fabricating nanodiamond coatings and composite materials is the difficulty of controlling the size, texture, and crystalline quality of the diamond particles. Now, researchers in Portugal have demonstrated for the first time the facile fabrication and the conformal coating of nanocrystalline diamond onto silica nanofibers by a two-step method: synthesis of templates on silicon wafer; and coating of the silica fibers with nanocrystalline diamond.

Apr 8th, 2008

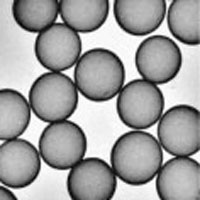

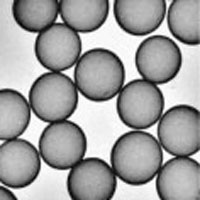

Lithium-ion batteries seem to be everywhere these days. They power most of the electronic devices we carry around with us - cell phones, laptops, MP3 players, digital cameras and so on. They get their name from the lithium ion that moves from the anode to the cathode during discharge and from the cathode to the anode during recharging. Due to their good energy-to-weight ratios, lithium batteries are some of the most energetic rechargeable batteries available today. In terms of weight and size, batteries have become one of the limiting factors in the continuous process of developing smaller and higher performance electronic devices. To meet the demand for batteries having higher energy density and improved cycle characteristics, researchers have been making tremendous efforts to develop new electrode materials or design new structures of electrode materials. Demonstrating the benefits of directed nanostructure-design of electrode materials, Chinese scientists have prepared tin nanoparticles encapsulated in elastic hollow carbon spheres. This tin-based nanocomposite exhibits a very high specific capacity, excellent cycling performance, and therefore shows great potential as anode materials in lithium-ion batteries.

Lithium-ion batteries seem to be everywhere these days. They power most of the electronic devices we carry around with us - cell phones, laptops, MP3 players, digital cameras and so on. They get their name from the lithium ion that moves from the anode to the cathode during discharge and from the cathode to the anode during recharging. Due to their good energy-to-weight ratios, lithium batteries are some of the most energetic rechargeable batteries available today. In terms of weight and size, batteries have become one of the limiting factors in the continuous process of developing smaller and higher performance electronic devices. To meet the demand for batteries having higher energy density and improved cycle characteristics, researchers have been making tremendous efforts to develop new electrode materials or design new structures of electrode materials. Demonstrating the benefits of directed nanostructure-design of electrode materials, Chinese scientists have prepared tin nanoparticles encapsulated in elastic hollow carbon spheres. This tin-based nanocomposite exhibits a very high specific capacity, excellent cycling performance, and therefore shows great potential as anode materials in lithium-ion batteries.

Apr 7th, 2008

The food industry is excited about the potential of nanotechnology. Food companies are very much involved in exploring and implementing nanotechnology applications in food processing, packaging and even growing - but you don't hear about it anymore. At least not from the companies. Large industrial food companies, no stranger to big and expensive media campaigns, have buried the subject of nanotechnology in their public relations graveyard. Take Kraft Foods for example. While it took the industry's nanotechnology lead when it established the Nanotek Consortium in 2000, it has since pulled back completely on the PR front. The Nanotek Consortium even was renamed the 'Interdisciplinary Network of Emerging Science and Technologies' (INEST), is now sponsored by Altria, and its single webpage makes no mention of food at all. Doing our regular check on the websites of large food companies we again found not a single reference to 'nanotechnology' or even 'nano'. The same is true for large food industry associations such as the Grocery Manufacturers/Food Products Association (GMA/FPA), which represents the world's leading food, beverage and consumer products companies. Faced with a complete nanotechnology communications blackout from the manufacturers, it is left to activist groups like Friends of the Earth to frame the discussion. These groups are trying to figure out what the food industry is up to and if there might be any risks involved that we should know about.

The food industry is excited about the potential of nanotechnology. Food companies are very much involved in exploring and implementing nanotechnology applications in food processing, packaging and even growing - but you don't hear about it anymore. At least not from the companies. Large industrial food companies, no stranger to big and expensive media campaigns, have buried the subject of nanotechnology in their public relations graveyard. Take Kraft Foods for example. While it took the industry's nanotechnology lead when it established the Nanotek Consortium in 2000, it has since pulled back completely on the PR front. The Nanotek Consortium even was renamed the 'Interdisciplinary Network of Emerging Science and Technologies' (INEST), is now sponsored by Altria, and its single webpage makes no mention of food at all. Doing our regular check on the websites of large food companies we again found not a single reference to 'nanotechnology' or even 'nano'. The same is true for large food industry associations such as the Grocery Manufacturers/Food Products Association (GMA/FPA), which represents the world's leading food, beverage and consumer products companies. Faced with a complete nanotechnology communications blackout from the manufacturers, it is left to activist groups like Friends of the Earth to frame the discussion. These groups are trying to figure out what the food industry is up to and if there might be any risks involved that we should know about.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed