Showing Spotlights 2553 - 2560 of 2851 in category All (newest first):

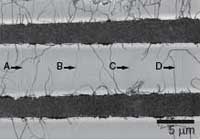

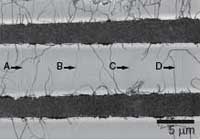

Synthesis of carbon nanotubes (CNTs) is a rapidly advancing field, but there is a lot that researchers don't know about how nanotubes form and grow. Synthesis, while rapidly developing, is currently the weakest link for most nanotube applications, with high yield and high precision diameter and chirality control being important goals. Historically, in situ characterization tools have accelerated progress in synthesis for many advanced materials, and there is widespread recognition that in situ tools have the potential to improve CNT synthesis as well. Ideally one would like to detect individual nanotubes and ensembles as they grow and measure their physical properties while imposing minimal constraints on the synthesis method. In other words, with a good understanding of the synthesis process we would be better able to control the product. It is feasible that by actually observing nanotubes as they grow one will gain a better understanding of the growth process and also better characterize the grown product. Greater control over the physical characteristics of the nanotube product is essential to enable many applications, as well as many fundamental studies. Although chemical vapor deposition (CVD) is now a very standard method to synthesize CNTs, there aren't really standard in situ tools to characterize nanotubes during growth. Researchers in Canada have now shown how global Raman imaging (GRI) can be used to characterize the CVD growth of CNTs in situ and in real time.

Synthesis of carbon nanotubes (CNTs) is a rapidly advancing field, but there is a lot that researchers don't know about how nanotubes form and grow. Synthesis, while rapidly developing, is currently the weakest link for most nanotube applications, with high yield and high precision diameter and chirality control being important goals. Historically, in situ characterization tools have accelerated progress in synthesis for many advanced materials, and there is widespread recognition that in situ tools have the potential to improve CNT synthesis as well. Ideally one would like to detect individual nanotubes and ensembles as they grow and measure their physical properties while imposing minimal constraints on the synthesis method. In other words, with a good understanding of the synthesis process we would be better able to control the product. It is feasible that by actually observing nanotubes as they grow one will gain a better understanding of the growth process and also better characterize the grown product. Greater control over the physical characteristics of the nanotube product is essential to enable many applications, as well as many fundamental studies. Although chemical vapor deposition (CVD) is now a very standard method to synthesize CNTs, there aren't really standard in situ tools to characterize nanotubes during growth. Researchers in Canada have now shown how global Raman imaging (GRI) can be used to characterize the CVD growth of CNTs in situ and in real time.

Apr 26th, 2007

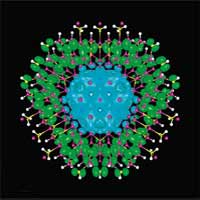

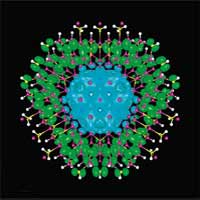

The promise of revolutionary bottom-up nanotechnology is based on a vision of molecular assembly technologies where nanoscale materials and structures self-assemble to microscale structures and finally to macroscopic devices and products. We are a long way from realizing this vision but researchers are busily laying the foundation for the things to come. Assembling nanoscopic components into macroscopic materials has been an appealing goal but one of the enormous difficulties lies in bridging approximately six orders of magnitude that separate the nanoscale from the macroscopic world. New research at Northwestern University in the U.S. helps to overcomes this difficulty by dividing the assembly process into two manageable sub-steps. First, nanoparticles are assembled into larger, 100 nm-size, spherical building blocks, which are both deformable and "sticky" towards one another. Once assembled, these components "glue" together like pieces of clay to give millimeter or even centimeter-sized structures. The novelty of this technique is both the hierarchical assembly approach (i.e., atoms to nanoparticles to supraspheres to macroscopic materials) and the resulting "soft" structures, which contrast with previously reported hard and brittle nanoparticles assemblies/crystals. This research takes a further step in making nanoscale discoveries relevant to our everyday - macroscopic - world.

The promise of revolutionary bottom-up nanotechnology is based on a vision of molecular assembly technologies where nanoscale materials and structures self-assemble to microscale structures and finally to macroscopic devices and products. We are a long way from realizing this vision but researchers are busily laying the foundation for the things to come. Assembling nanoscopic components into macroscopic materials has been an appealing goal but one of the enormous difficulties lies in bridging approximately six orders of magnitude that separate the nanoscale from the macroscopic world. New research at Northwestern University in the U.S. helps to overcomes this difficulty by dividing the assembly process into two manageable sub-steps. First, nanoparticles are assembled into larger, 100 nm-size, spherical building blocks, which are both deformable and "sticky" towards one another. Once assembled, these components "glue" together like pieces of clay to give millimeter or even centimeter-sized structures. The novelty of this technique is both the hierarchical assembly approach (i.e., atoms to nanoparticles to supraspheres to macroscopic materials) and the resulting "soft" structures, which contrast with previously reported hard and brittle nanoparticles assemblies/crystals. This research takes a further step in making nanoscale discoveries relevant to our everyday - macroscopic - world.

Apr 25th, 2007

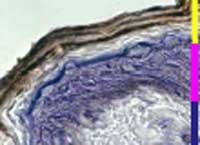

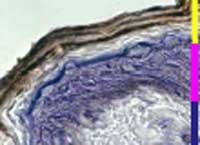

Engineered nanoparticles are at the forefront of the rapidly developing field of nanomedicine. Their unique size-dependent properties, of which optical and magnetic effects are the most used for biological applications, makes them suitable for a wide range of biomedical applications such as cell labeling and targeting, tissue engineering, drug delivery and drug targeting, magnetic resonance imaging, probing of DNA structure, tumor destruction via heating (hyperthermia), and detection and analysis of biomolecules such as proteins or pathogens. Many of these applications can also be tailored to target skin to help in the early diagnosis of a skin disease, which then could also be treated via nanocarriers. In addition, a tissue engineering approach could be useful for skin wound healing therapies and the magnetic properties of these particles might help in directing and localizing these agents in a particular layer of the skin where their action is desired. Unfortunately, if nanoparticles are able to penetrate layers of skin for therapeutic purposes, they might equally be able to penetrate skin unintentionally. This raises the question if people, who are exposed to such nanomaterials, could accidentally be contaminated and thus exposed to a potential local and/or systemic health risk. Researchers in Italy now have begun to systematically evaluate both risks and applications of nanoparticle skin absorption.

Engineered nanoparticles are at the forefront of the rapidly developing field of nanomedicine. Their unique size-dependent properties, of which optical and magnetic effects are the most used for biological applications, makes them suitable for a wide range of biomedical applications such as cell labeling and targeting, tissue engineering, drug delivery and drug targeting, magnetic resonance imaging, probing of DNA structure, tumor destruction via heating (hyperthermia), and detection and analysis of biomolecules such as proteins or pathogens. Many of these applications can also be tailored to target skin to help in the early diagnosis of a skin disease, which then could also be treated via nanocarriers. In addition, a tissue engineering approach could be useful for skin wound healing therapies and the magnetic properties of these particles might help in directing and localizing these agents in a particular layer of the skin where their action is desired. Unfortunately, if nanoparticles are able to penetrate layers of skin for therapeutic purposes, they might equally be able to penetrate skin unintentionally. This raises the question if people, who are exposed to such nanomaterials, could accidentally be contaminated and thus exposed to a potential local and/or systemic health risk. Researchers in Italy now have begun to systematically evaluate both risks and applications of nanoparticle skin absorption.

Apr 24th, 2007

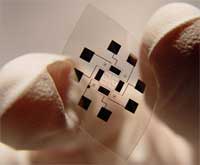

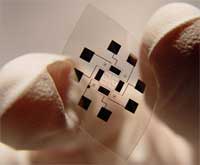

The fabrication of electronic devices on plastic substrates has attracted considerable recent attention owing to the proliferation of handheld, portable consumer electronics. Plastic substrates possess many attractive properties including biocompatibility, flexibility, light weight, shock resistance, softness and transparency. Achieving high performance electronics or sensors on plastic substrates is difficult, because plastics melt at temperatures above 120 degrees C. Central to continued advances in high-performance plastic electronics is the development of robust methods for overcoming this temperature restriction. Unfortunately, high quality semiconductors (such as silicon) require high growth temperatures, so their application to flexible plastics is prohibited. A group of researchers at the California Institute of Technology now showed that highly ordered films of silicon nanowires can be literally glued onto pieces of plastic to make flexible sensors with state-of-the-art sensitivity to a range of toxic chemicals. These nanowires are crystalline wires made out of doped silicon - the mainstay of the computer industry. By etching nanowires into a wafer of silicon, and then peeling them off and transferring them to plastic, they developed a general, parallel, and scalable strategy for achieving high performance electronics on low cost plastic substrates.

The fabrication of electronic devices on plastic substrates has attracted considerable recent attention owing to the proliferation of handheld, portable consumer electronics. Plastic substrates possess many attractive properties including biocompatibility, flexibility, light weight, shock resistance, softness and transparency. Achieving high performance electronics or sensors on plastic substrates is difficult, because plastics melt at temperatures above 120 degrees C. Central to continued advances in high-performance plastic electronics is the development of robust methods for overcoming this temperature restriction. Unfortunately, high quality semiconductors (such as silicon) require high growth temperatures, so their application to flexible plastics is prohibited. A group of researchers at the California Institute of Technology now showed that highly ordered films of silicon nanowires can be literally glued onto pieces of plastic to make flexible sensors with state-of-the-art sensitivity to a range of toxic chemicals. These nanowires are crystalline wires made out of doped silicon - the mainstay of the computer industry. By etching nanowires into a wafer of silicon, and then peeling them off and transferring them to plastic, they developed a general, parallel, and scalable strategy for achieving high performance electronics on low cost plastic substrates.

Apr 23rd, 2007

Nanowires have received a great deal of interest in recent years. As quasi one-dimensional systems they may overcome the fundamental difficulty in the electronic transport encountered when attempting to use quasi zero-dimensional structures (quantum dots) while still being able to take advantage of the effects related to quantum confinement. In a conventional semiconductor, electrons and holes typically stay in the same region after photoexcitation, which is very desirable for certain applications, light-emitting devices for instance. However, for a number of key renewable energy applications, including hydrogen generation via photoelectrochemical water splitting, dye-sensitized solar cells, and even regular solar cells, the efficient charge separation of the electron and hole after photoexcitation is instead highly preferred, although not readily available in the existing repertory of materials. In this context, researchers have explored the use of core-shell nanowires for such applications. However, for the material combinations that have been investigated, the energy alignments between the core and the shell are typically type I, and thus, the role of the shell is to either provide quantum confinement to both electrons and holes in the core or a protective cladding to the core to reduce sensitivity to the environment. Researchers at the National Renewable Energy Laboratory and Lawrence Berkeley National Laboratory designed a new class of core-shell semiconductor nanowires with strong type II band alignments. The photo-generated electron and hole in such nanowires are naturally separated in the core and shell, respectively, making them much more suitable for the solar energy applications than type I core-shell nanowires.

Nanowires have received a great deal of interest in recent years. As quasi one-dimensional systems they may overcome the fundamental difficulty in the electronic transport encountered when attempting to use quasi zero-dimensional structures (quantum dots) while still being able to take advantage of the effects related to quantum confinement. In a conventional semiconductor, electrons and holes typically stay in the same region after photoexcitation, which is very desirable for certain applications, light-emitting devices for instance. However, for a number of key renewable energy applications, including hydrogen generation via photoelectrochemical water splitting, dye-sensitized solar cells, and even regular solar cells, the efficient charge separation of the electron and hole after photoexcitation is instead highly preferred, although not readily available in the existing repertory of materials. In this context, researchers have explored the use of core-shell nanowires for such applications. However, for the material combinations that have been investigated, the energy alignments between the core and the shell are typically type I, and thus, the role of the shell is to either provide quantum confinement to both electrons and holes in the core or a protective cladding to the core to reduce sensitivity to the environment. Researchers at the National Renewable Energy Laboratory and Lawrence Berkeley National Laboratory designed a new class of core-shell semiconductor nanowires with strong type II band alignments. The photo-generated electron and hole in such nanowires are naturally separated in the core and shell, respectively, making them much more suitable for the solar energy applications than type I core-shell nanowires.

Apr 20th, 2007

There seems to be an arms race going on among nanotechnology investment and consulting firms as to who can come up with the highest figure for the size of the "nanotechnology market". The current record stands at $2.95 trillion by 2015. The granddaddy of the trillion-dollar forecasts of course is the National Science Foundation's (NSF) "$1 trillion by 2015", which inevitably gets quoted in many articles, business plans and funding applications. The "nanotechnology market" as a unified market was first quantified by the NSF in its massive 280-pages report from March 2001. The problem with these forecasts is that they are based on a highly inflationary data collection and compilation methodology. The result is that the headline figures - $1 trillion!, $2 trillion!, $3 trillion! - are more reminiscent of supermarket tabloids than serious market research. Some would call it pure hype. This type of market size forecast leads to misguided expectations because few people read the entire report and in the end only the misleading trillion-dollar headline figure gets quoted out of context, even by people who should now better, and finally achieves a life by itself.

There seems to be an arms race going on among nanotechnology investment and consulting firms as to who can come up with the highest figure for the size of the "nanotechnology market". The current record stands at $2.95 trillion by 2015. The granddaddy of the trillion-dollar forecasts of course is the National Science Foundation's (NSF) "$1 trillion by 2015", which inevitably gets quoted in many articles, business plans and funding applications. The "nanotechnology market" as a unified market was first quantified by the NSF in its massive 280-pages report from March 2001. The problem with these forecasts is that they are based on a highly inflationary data collection and compilation methodology. The result is that the headline figures - $1 trillion!, $2 trillion!, $3 trillion! - are more reminiscent of supermarket tabloids than serious market research. Some would call it pure hype. This type of market size forecast leads to misguided expectations because few people read the entire report and in the end only the misleading trillion-dollar headline figure gets quoted out of context, even by people who should now better, and finally achieves a life by itself.

Apr 19th, 2007

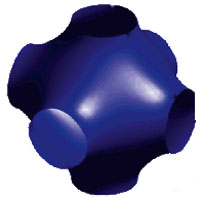

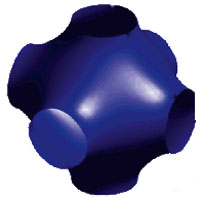

Self assembled structures from colloidal particles have many applications in biology, as chemical sensors and as photonic crystals. The control of shape and valency of the colloidal particle is very important since it will determine the 3D lattices of the assembled structure. There have been several prior effort to fabricating particles with complex shapes. Most particles with anisotropic shape are from the simple assembly of spheres or the modification of spherical particles. Interference lithography is one of the few techniques which can provide direct and systematic control over symmetry and volume fraction of the 3D structure. It involves the simple creation of interference patterns in a photoresist systems and subsequent pinch off of the parent structure through a drying process. Researchers at MIT have now presented a new facile and high-yield route for the fabrication of highly nonspherical complex multivalent nanoparticles. This technique exploits the ability of holographic interference lithography to control network topology. These research results could lay the groundwork for establishing and demonstrating control over particle shape in colloidal nanoparticles.

Self assembled structures from colloidal particles have many applications in biology, as chemical sensors and as photonic crystals. The control of shape and valency of the colloidal particle is very important since it will determine the 3D lattices of the assembled structure. There have been several prior effort to fabricating particles with complex shapes. Most particles with anisotropic shape are from the simple assembly of spheres or the modification of spherical particles. Interference lithography is one of the few techniques which can provide direct and systematic control over symmetry and volume fraction of the 3D structure. It involves the simple creation of interference patterns in a photoresist systems and subsequent pinch off of the parent structure through a drying process. Researchers at MIT have now presented a new facile and high-yield route for the fabrication of highly nonspherical complex multivalent nanoparticles. This technique exploits the ability of holographic interference lithography to control network topology. These research results could lay the groundwork for establishing and demonstrating control over particle shape in colloidal nanoparticles.

Apr 17th, 2007

Nano-this and nano-that. These days it seems you need the prefix "nano" for products or applications if you want to be either very trendy or incredibly scary. This "nanotrend" has assumed "mega" proportions: Patent offices around the world are swamped with nanotechnology-related applications; investment advisors compile nanotechnology stock indices and predict a coming boom in nanotechnology stocks with misleading estimates floating around of a trillion-dollar industry within 10 years; pundits promise a new world with radically different medical procedures, manufacturing technologies and solutions to environmental problems; nano conferences and trade shows are thriving all over the world; scientific journals are awash in articles dealing with nanoscience discoveries and nano- technology breakthroughs. Nanotechnology has been plagued by a lot of hype, but cynicism and criticism have not been far behind. Science fiction writers exploit fears of nanorobots turning into killers; the media can run amok when news about potential health problems with nanoproducts surface (as happened last year with a product recall for a bathroom cleaner in Germany). Some see doomsday scenarios of molecular self-assembly turning the world into "grey goo." The emerging polarization of opinions on nanotechnology is reminiscent of controversies about genetically modified plants or nuclear energy. Vague promises of a better life are met by equally vague, generalized fears about a worse future. These debates have some aspects in common: the subject is complex and not easy to explain; there is no consensus on risks and benefits; scientists and corporations seem able to proceed unchecked, and it is unclear who is in control.

Nano-this and nano-that. These days it seems you need the prefix "nano" for products or applications if you want to be either very trendy or incredibly scary. This "nanotrend" has assumed "mega" proportions: Patent offices around the world are swamped with nanotechnology-related applications; investment advisors compile nanotechnology stock indices and predict a coming boom in nanotechnology stocks with misleading estimates floating around of a trillion-dollar industry within 10 years; pundits promise a new world with radically different medical procedures, manufacturing technologies and solutions to environmental problems; nano conferences and trade shows are thriving all over the world; scientific journals are awash in articles dealing with nanoscience discoveries and nano- technology breakthroughs. Nanotechnology has been plagued by a lot of hype, but cynicism and criticism have not been far behind. Science fiction writers exploit fears of nanorobots turning into killers; the media can run amok when news about potential health problems with nanoproducts surface (as happened last year with a product recall for a bathroom cleaner in Germany). Some see doomsday scenarios of molecular self-assembly turning the world into "grey goo." The emerging polarization of opinions on nanotechnology is reminiscent of controversies about genetically modified plants or nuclear energy. Vague promises of a better life are met by equally vague, generalized fears about a worse future. These debates have some aspects in common: the subject is complex and not easy to explain; there is no consensus on risks and benefits; scientists and corporations seem able to proceed unchecked, and it is unclear who is in control.

Apr 16th, 2007

Synthesis of carbon nanotubes (CNTs) is a rapidly advancing field, but there is a lot that researchers don't know about how nanotubes form and grow. Synthesis, while rapidly developing, is currently the weakest link for most nanotube applications, with high yield and high precision diameter and chirality control being important goals. Historically, in situ characterization tools have accelerated progress in synthesis for many advanced materials, and there is widespread recognition that in situ tools have the potential to improve CNT synthesis as well. Ideally one would like to detect individual nanotubes and ensembles as they grow and measure their physical properties while imposing minimal constraints on the synthesis method. In other words, with a good understanding of the synthesis process we would be better able to control the product. It is feasible that by actually observing nanotubes as they grow one will gain a better understanding of the growth process and also better characterize the grown product. Greater control over the physical characteristics of the nanotube product is essential to enable many applications, as well as many fundamental studies. Although chemical vapor deposition (CVD) is now a very standard method to synthesize CNTs, there aren't really standard in situ tools to characterize nanotubes during growth. Researchers in Canada have now shown how global Raman imaging (GRI) can be used to characterize the CVD growth of CNTs in situ and in real time.

Synthesis of carbon nanotubes (CNTs) is a rapidly advancing field, but there is a lot that researchers don't know about how nanotubes form and grow. Synthesis, while rapidly developing, is currently the weakest link for most nanotube applications, with high yield and high precision diameter and chirality control being important goals. Historically, in situ characterization tools have accelerated progress in synthesis for many advanced materials, and there is widespread recognition that in situ tools have the potential to improve CNT synthesis as well. Ideally one would like to detect individual nanotubes and ensembles as they grow and measure their physical properties while imposing minimal constraints on the synthesis method. In other words, with a good understanding of the synthesis process we would be better able to control the product. It is feasible that by actually observing nanotubes as they grow one will gain a better understanding of the growth process and also better characterize the grown product. Greater control over the physical characteristics of the nanotube product is essential to enable many applications, as well as many fundamental studies. Although chemical vapor deposition (CVD) is now a very standard method to synthesize CNTs, there aren't really standard in situ tools to characterize nanotubes during growth. Researchers in Canada have now shown how global Raman imaging (GRI) can be used to characterize the CVD growth of CNTs in situ and in real time.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed