| Posted: Dec 15, 2011 | |

Lesson from nature greatly strengthens the potential of block copolymer lithography |

|

| (Nanowerk Spotlight) As we discussed in a recent Nanowerk Spotlight, directed self-assembly of block copolymers is a candidate lithography for use in future nanoelectronics and patterned media copolymer with resolutions down to the sub-10nm domain ("Novel nanoimprint technique offers a low-cost route toward sub-10 nm nanopatterning"). Block copolymer lithography is a cost-effective, parallel, and scalable nanolithography for the densely packed periodic arrays of nanoscale features, whose typical dimension scale is beyond the resolution limit of conventional photolithography. | |

| "So far, it has been impossible to utilize block copolymer lithography on low surface energy materials such as Teflon, graphene or gold, where block copolymer thin film generally de-wets," Sang Ouk Kim, an associate professor in the Department of Materials Science and Engineering at KAIST, tells Nanowerk. "Surface energy has a delicate influence on the molecular ordering and the nanodomain alignment of self-assembling materials and currently available methods are substrate-specific and unable to modify low surface energy or chemically inert surfaces." | |

| To address this technological challenge, Kim and his team introduced block copolymer lithography that employs polydopamine coating – inspired by the adhesive proteins secreted by mussels – as a surface pretreatment for universal wettability generally applicable to arbitrary surfaces. | |

| They demonstrate that the catechol group in the polydopamine layer can both act as a further chemical modification site for block copolymer lithography, as well as a universal surface adhesive on those low surface energy substrates. | |

| The researchers published their findings in a recent edition of Advanced Materials ("Mussel-Inspired Block Copolymer Lithography for Low Surface Energy Materials of Teflon, Graphene, and Gold"). | |

|

|

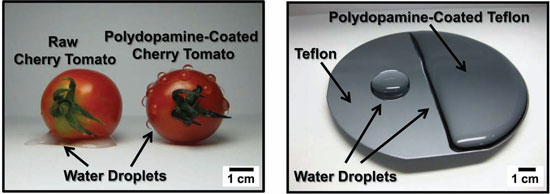

| Mussel-inspired surface engineering of cherry tomato and Teflon film. Both the hydrophobic cherry tomato and the synthetic Teflon film surface became dramatically hydrophilic by polydopamine treatment. (Reprinted with permission from Wiley-VCH Verlag) | |

| Many research efforts have tried to broaden the potential applicability of block copolymer lithography. Nevertheless, all previous efforts relying on solution casting process revealed intrinsic limitation for low surface energy materials, where solution casting itself is impossible. | |

| The Korean researchers addressed this long-standing challenge in their work. As a result, they were able to fabricate, for example, Teflon nanowire arrays by block copolymer lithography, which so far have never been achieved – Teflon is one of the lowest surface energy materials, where solution casting is impossible. | |

| "We also demonstrated the versatility of the polydopamine treatment by the surface modification of a raw cherry tomato," says Kim (see above figure). "A raw cherry tomato is a challenging object for surface modification due to its nonplanar morphology consisting of soft biomolecules. In the figure above, on the left is a raw cherry tomato with a fairly low energy surface. Water droplets readily de-wetted from the raw cherry tomato surface. The right one is the polydopamine treated cherry tomato, whose surface energy was greatly enhanced such that water droplets were stably stuck at the non-planar geometry." | |

| Kim points out that this novel nanofabrication approach is potentially useful for the nanopatterning of superhydrophobic surfaces and carbon electronic devices, consisting of carbon nanotubes and graphene. | |

| The next goal the team has in its sight is to further develop block copolymer lithography for the nanopatterning of the non-planar or soft/flexible substrates. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|