| Posted: Aug 07, 2017 | |

Harvesting water energy with a wearable, all-fabric triboelectric generator |

|

| (Nanowerk Spotlight) Wearable energy harvesters have received much research attention in recent years, aiming at powering various emerging flexible and wearable electronics to meet the requirements of smart fabrics, motion tracking and health monitoring. | |

| Scientists already have developed several ways to harvest small amounts of energy from motion in the world around us. These tiny triboelectric generators (TEGs) for instance can be "powered by ultrasonic waves, convert heartbeat and breathing into electricity, and harvest waste energy from a rotating tire. | |

| Another example are water-based TEGs (WTEGs) that collect the electric energy generated from flowing water. Until now, almost all the WTEGs were designed based on synthetic polymer films. | |

| "Indeed, these synthetic polymers show good water-resistance, low dielectric constant, high thermal stability, good mechanical strength, and plasticity which are important to meet the applications of high-performance WTEG electronics," Pooi See Lee, a professor in the School of Materials Science and Engineering at Nanyang Technological University, tells Nanowerk. "However, most of these flat polymeric substrates are not effective for fabricating a practical wearable device due to its low flexibility, limited deformability or stretchability." | |

| In new work, Lee and her team have developed a coating based on cellulose-derived hydrophobic nanoparticles and demonstrated its application as a wearable water triboelectric generator that harvests energy from water flow. This innovative fabric-based TEG has self-cleaning and antifouling properties. | |

| As they report in Advanced Energy Materials ("Wearable All-Fabric-Based Triboelectric Generator for Water Energy Harvesting"), the preparation method is an eco-friendly and generic strategy to realize waterproof coatings sprayable on a myriad of substrates for extensive applications. | |

|

|

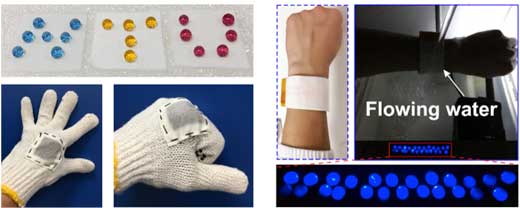

| Photograph of the coated PET fabric that holds the dyes even after washed for 72 hours, indicating a robust superhydrophobic coating. The PET fabric-based WTEG can be mounted onto a cotton glove and wristband, and it drives the array of LEDs under flow of water. (Reprinted with permission by Wiley-VCH Verlag) (click on image to enlarge) | |

| "It is a very simple process to achieve various superhydrophobic daily textiles with additional self-cleaning and antifouling performance," Jiaqing Xiong, the postdoctoral fellow who worked on this project, points out. "The water triboelectric generator (WTEG) is conformable, delivers excellent breathability and washability, and it can be easily incorporated into other textiles, or directly harvest water energy for powering various wearable electronics." | |

| So far it has been a challenge to achieve TEGs directly on fabrics or textiles due to the poor water resistance of fabrics (both natural and synthetic) related to their intrinsic hydrophilicity that can be ascribed to their abundant hydrophilic groups, and the strong adsorption capacity due to their large specific surface area. | |

| The researchers overcame these hurdles by preparing cellulose derived hydrophobic nanoparticles using a nontoxic esterification method and nanoprecipitation technology. The starting materials are prepared from microcrystalline cellulose, a natural polymer often used in food production, cosmetics and pharmaceutical industries. | |

| The working mechanism of the resulting WTEG is based on the triboelectricity created from the contact electrification process between water droplets with the surface of the WTEG. Since the flowing water not only produces triboelectricity but also carries mechanical energy, the team fabricated an packaged all-fabric-based dual-mode TEG (DMTEG) that combines the configuration of a WTEG and a contact-TEG in order to collect both energy forms. | |

| A proof-of-principle experimental set-up showed that the DMTEG could power commercial LEDs from the energy harvested from tap water flowing rate of 10 mL per second. | |

| The amount of energy generated can be used for simple wearables; in order to drive larger electronics, a larger device area coverage is required. | |

| Going forward, the scientists will be focusing on large-scale preparation of the nanoparticles and assessing other functional properties of the coatings such as antifouling or antibacterial evaluations in various conditions. | |

| "As a next step, we will further develop our 'green' hydrophobic spray to other substrates for harvesting rain/water energy," Lee concludes. "We will integrate some other functional devices (solar cell, supercapacitor, sensors) into our WTEGs to achieve multifunctional self-powered wearable devices." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|