| Posted: Feb 08, 2010 | |

A practical example of solving environmental problems utilizing nanotechnology |

|

| (Nanowerk Spotlight) Carbon nanotubes (CNTs) are 'strange' nanostructures in a sense that they have both high mechanical strength and extreme flexibility. Deforming a carbon nanotube into any shape would not easily break the structure, and it recovers to original morphology in perfect manner. Researchers in China are exploiting this phenomenon by making CNT sponges consisting of a large amount of interconnected nanotubes, thus showing a combination of useful properties such as high porosity, super elasticity, robustness, and little weight (1% of water density). | |

| The nanotube sponges not only show exciting properties as a porous material but they also are very promising to be used practically in a short time. The production method is simple and scalable, the cost is low, and the sponges can find immediate use in many fields related to water purification. | |

| "We hope to give an example to industry that this sponge is a real thing they can prepare at low cost, make versatile products with high performance, and solve environmental problems utilizing nanotechnology," Anyuan Cao, a professor in the Department of Advanced Materials and Nanotechnology at Peking University, tells Nanowerk. | |

|

|

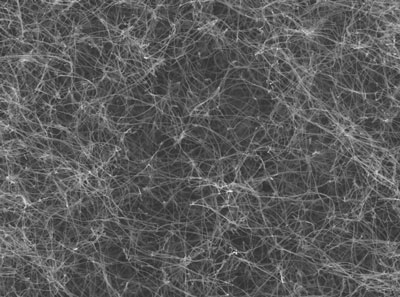

| Cross-sectional SEM image of the sponge showing a porous morphology and overlapped CNTs. (Image: Dr. Cao, Peking University) | |

| Cao explains that the nanotube sponges are a completely new structure compared with artificial porous materials in several aspects: The sponge is built entirely with nanotubes through a random (yet desired) interconnection. With a high porosity of >99%, the sponge can be compressed to less than 10% of its original volume yet still recover perfectly. Usually, porous materials (e.g. silica aerogels) tend to become brittle at increasing porosity, thus obtaining a material with both high porosity and flexibility has been challenging. | |

| "Plastic foams can be deformed in a similar way to our sponges, but they do not have such high elasticity (full structural recovery) and stability at high temperature" says Cao. "I think that the soft and elastic nanotube sponges are actually similar to some biological cellulose scaffolds." | |

| The motivation of the team – Cao's group and collaborators from Tsinghua University –is to explore potential applications of nanotechnology, especially in energy and environmental areas. | |

| Cao notes that fabricating porous materials with nanostructures such as carbon nanotubes could take advantage of their high surface area and excellent mechanical strength and flexibility. "We have accumulated much experience in synthesizing macroscale products in recent years, and when we made this sponge-like nanotube bricks, we became convinced that they could find use in absorbing solvents, oils, even metal ions." | |

| The scientists synthesized the sponges by a chemical vapor deposition (CVD) process during which the CNTs (multi-walled nanotubes with diameters in the range of 30 to 50nm and lengths of tens to hundreds of micrometers,) self-assembled into a porous, interconnected, three-dimensional framework. | |

| "Our CVD method is similar to that was reported for growing vertical CNT arrays, but we used a different carbon source (dichlorobenzene) to disturb the aligned growth and obtain a randomly interconnected structure," explains Cao. "The growth process of the sponges can be seen as a consecutive stacking and penetration of numerous CNT 'piles' into centimeter thickness, which is substantially different from aligned arrays where most of CNTs grow continuously from the bottom to top surface or thin sheets where CNTs were densified into a two-dimensional network during vacuum filtration." | |

| According to the scientists, the CNT sponges are capable of absorbing a wide range of solvents and oils with excellent selectivity, recyclability, and absorption capacities up to 180 times their own weight, two orders of magnitude higher than activated carbon. | |

|

|

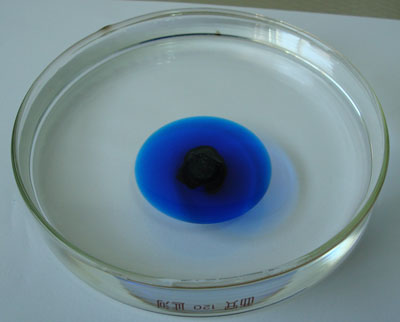

| Snapshot showing the absorption of a 28 square centimeter and millimeter-thick vegetable oil film (dyed with Oil Blue) distributed on a water bath by a small spherical sponge. The growing size of the sponge accompanied by the shrinkage of oil film indicates continuous oil absorption and storage inside the sponge. (Image: Dr. Cao, Peking University) | |

| The potential application areas for these sponges is vast. They could be used in large-area oil spill clean-ups (A small densified pellet floating on water surface can quickly remove a spreading oil film with an area up to 800 times that of the sponge), water purification (by targeted absorption of small dusts and unwanted molecules/ions from water), and toxic gas filtration. In addition to environmental applications, the CNT sponges can find use as protective coating, thermal insulator, and high strength-to-weight composite. For example, the sponges can absorb mechanical energy during large-strain deformation, therefore resist foreign force or impact. Their high surface area and porosity are also useful for supporting fine catalyst particles in photo-catalytic devices and fuel cells. | |

| Cao cautions that safety concerns of this sponge material need to be explored before extensive use in certain situations (e.g. in water) can take place. While the sponge can be compressed arbitrarily and repeatedly, its tensile strength is relatively small – it is weak when you pull. This could cause the structure to split in certain conditions, for example, under bending or tensile stress. It is also possible that individual nanotubes detach from the sponge body during use, which could be problematic as chemical interaction of CNTs with human tissue and organs is still unclear. | |

| "Despite of that, there are many ways to strengthen and secure our sponges to ensure the safety of those nano-products" says Cao. | |

| Currently, the team are working on making better samples with larger size. Of particular interest is to tailor the structure and properties of the nanotube sponges to facilitate different applications. | |

| "We can already control pore size, internal surface area, electrical and mechanical properties (related to the structure of individual nanotubes and how they are assembled) during synthesis and post-treatment" says Cao. "We are also involving methods such as chemical functionalization to make CNT sponges more or less attract specific molecules. Because the sponge pore size is relatively large (several to tens of nanometers), small molecules (e.g. gas, ions) are difficult to be absorbed and immobilized inside pristine-form sponges. It is challenging to find suitable chemical routes that can make the sponges selectively remove those molecules from water or environment, after that anchor and store them in a safe manner." | |

| The team has published their findings in a recent issue of Advanced Materials ("Carbon Nanotube Sponges"). | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|