| Posted: Jan 20, 2011 | |

Nanocomposite approach enhances the performance of thermoelectric materials |

|

| (Nanowerk Spotlight) Thermoelectric energy conversion could pave the way for a broad application in the utilization of waste heat, for example in automobiles, or even of human body heat for portable electronics in textiles. Thermoelectric devices are energy converters – they are based on the fact that when certain materials are heated, they generate a significant electrical voltage; conversely, when a voltage is applied to them, they become hotter on one side, and colder on the other. The process works with a variety of materials, and especially well with semiconductors. | |

| Thermoelectric materials therefore hold great promise for turning waste heat back into useful power and are touted for use in hybrid cars, new and efficient refrigerators, and other cooling or heating applications. But they have one big drawback: they are very inefficient. | |

| Efficient thermoelectric materials need to be very good at conducting electricity, but not heat – and that's the problem; these materials are not efficient enough to be practical. In most materials, electrical and thermal conductivity go hand in hand. So researchers have to find ways of boosting the performance of thermoelectric materials by separating the two properties. | |

| The goal for efficiency is a value of 1 or more for a performance measurement called the thermoelectric figure of merit or ZT, which combines the electric and thermal conductivities of a material with its capacity to generate electricity from heat. Because, as mentioned above, these parameters are generally interdependent, attaining this goal has proven extremely difficult. | |

| Half-Heusler compounds and the structurally similar Heusler materials are intermetallic compounds made from three elements that form a cubic crystal structure. | |

| "Half-Heuslers could be important thermoelectric materials due to their high temperature stability and abundance if their dimensionless thermoelectric figure of merit could be boosted," Xiao Yan tells Nanowerk. "The highest peak ZT of a p-type half-Heusler has been so far reported about 0.5 due to the high thermal conductivity." | |

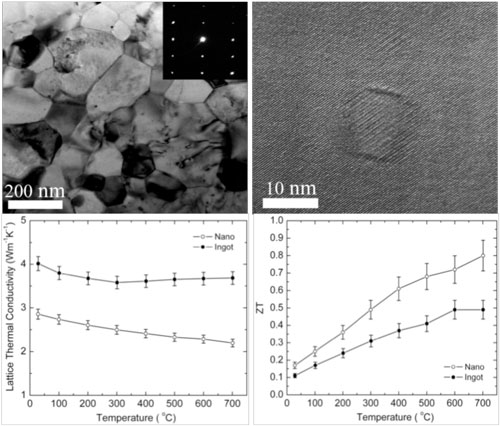

| Using a nanocomposite approach, Yan, a research associate in the Department of Physics at Boston College working in Zhifeng Ren's group, together with collaborators from MIT, led by Gang Chen, managed to increase the peak ZT from 0.5 (for bulk ingot) to 0.8 (the team's nanostructured sample) at 700 °C. At medium temperatures, they even were able to reach improvements of up to 90%. Also contributing to the work were Prof. S. J. Poon from University of Virginia and Prof. T. M. Tritt from Clemson University. | |

|

|

| TEM images of hot-pressed nanostructured samples under low (top left) and high (top right) magnification and Temperature-dependent lattice part of thermal conductivity (bottom left) and ZT (bottom right) of ball-milled and hot-pressed sample in comparison with that of the ingot. (Reprinted with permission from American Chemical Society) | |

| Yan, who is first author of a recent paper in Nano Letters ("Enhanced Thermoelectric Figure of Merit of p-Type Half-Heuslers") says that this work paves the way for half-Heuslers to become competitive candidates used in car exhaust system and other waste power generation systems. For their experiments, the research team loaded an alloyed bulk ingot of a half-Heusler alloy (with a composition of Zr0.5Hf0.5CoSb0.8Sn0.2) into a jar with grinding balls and then subjected to a mechanical ball-milling process. The resulting nanopowder with particles as small as 5 to 10 nanometers were then reconstructed into bulk form by pressing them into pellets with a diameter of 12.7 mm by the direct current induced hotpress method. | |

| "Our technique is a low-cost method that can be easily scaled for mass production," says Ren. | |

| Yan notes that microstructure studies show that average grain sizes of the obtained half-Heusler samples range from 100 to 200 nm, which is the smallest obtained in half-Heusler system. | |

| "The greatly reduced grain sizes associated with increased number of interfaces can effectively reflect the heat flow without impeding electrical current, causing a great suppression of thermal conductivity," he explains. "More surprisingly, transport property measurements show that not only is thermal conductivity greatly reduced as expected, but electronic properties (Seebeck coefficient) are also enhanced, which is very unusual in thermoelectric materials." | |

| "It is the best scenario for a thermoelectric material" says Chen. "Think about it: you are enhancing the electronic transport properties while simultaneously hindering the passage of heat flow. Lower thermal conductivity together with higher Seebeck coefficient, gives a drastic efficiency boost to this material: 60-90% higher for the whole temperature range." | |

| The Boston College and MIT team, lead by Ren and Chen, is now making efforts to prevent grain growth during the hot-pressing process of the bulk samples. Because the average grain size of 100-200 nm of the hot pressed bulk samples is much larger than the 5-10 nm of the ball-milled precursor nanopowders, the lattice thermal conductivity is still very high. | |

| "If we can preserve the grain size of the original nanopowders, a much lower thermal conductivity and thus a much higher ZT can be expected" says Ren. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|