| Posted: Jun 18, 2014 | |

The promise of nanotechnology for the next generation of lithium-ion batteries (page 1 of 3) |

|

| (Nanowerk Spotlight) Despite the recently reported battery-flaming problem of lithium-ion batteries (LIBs) in Boeing’s 787 Dreamliners and laptops (in 2006), LIBs are now successfully being used in many sectors. Consumer gadgets, electric cars, medical devices, space and military sectors use LIBs as portable power sources and in the future, spacecraft like James Webb Space Telescope are expected to use LIBs. The main reason for this rapid domination of LIB technology in various sectors is that it has the highest electrical storage capacity with respect to its weight (one unit of LIB can replace two nickel-hydrogen battery units). | |

| Also, LIBs are suitable for applications where both high energy density and power density are required, and in this respect, they are superior to other types of rechargeable batteries such as lead-acid, nickel-cadmium, nickel-metal hydride, nickel-metal batteries, etc. | |

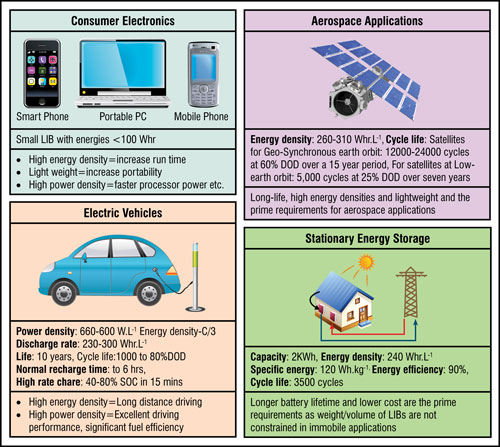

| However, LIBs are required to improve in the following aspects: (i) store more energy and deliver higher power for longer duration of time, (ii) get charged in shorter period of time, (iii) have a longer life-time and (iv) be resistant to fire hazards. Figure 1 depicts the basic LIB Characteristics required for different applications and the respective properties that need to be improved. | |

|

|

| Fig. 1: Basic LIB characteristics required for different applications 1,2 (DOD: Depth of Discharge, SOC: State of Charge). (click on image to enlarge) | |

| At present, there is a great deal of interest to upgrade the existing LIBs with improved properties and arrive at a battery technology that would permit smart-storage of electric energy. Futuristic smart electric grids that can provide an uninterruptible power supply to a household for 24 hours can replace the currently used lead acid battery systems by performing better in terms of longer back up time and reduced space requirements. With the advent of next generation LIBs, electric vehicles are expected to cover longer distances with shorter charging times; mobile phones and laptops are expected to be charged within minutes and last longer. | |

| Nanotechnology batteries | |

| Nanotechnology has the potential to deliver the next generation batteries, especially lithium-ion batteries, with improved performance, durability and safety at an acceptable cost. A typical LIB consists of three main components: an anode (generally made of graphite and other conductive additives), a cathode (generally, a layered transition metal oxide) and electrolyte through which lithium ions shuttles between the cathode and anode during charging and discharging cycles. | |

| On electrodes: The electrodes of LIB, both anode and cathode are made of materials that have the ability to be easily intercalated with lithium ions. The electrodes also should have high electrical conductivity so that the LIB can have high charging rates. Faster intercalation of Li ions can be facilitated by using nanosized materials for electrodes, which offer high surface areas and short diffusion paths, and hence faster storage and delivery of energy. One prominent example is the cathode material of A123 LIBs that use nanosized lithium iron phosphate cathode. Researchers have been trying to increase the electrical conductivity of lithium iron phosphate by doping it with metals. | |

| However, without the need for doping, the conductivity and hence the performance of the cathode material could be improved significantly by using nano-sized lithium iron phosphate. | |

| One dimensional vanadium oxide materials, LiCoO2 nanofibers, nanostructured spinels (LiMn2O4) and phosphor-olivines (LiFePO4), etc., are being explored as cathode materials for the next generation LIBs. Similarly, nanosizing the anode materials can make the anode to have short mass and charge pathways (i.e allow easier transport of both lithium ions and electrons) resulting in high reverse capacity and deliver at a faster rate. | |

| Nanostructured materials like silicon nanowires, silicon thin films, carbon nanotubes, graphene, tin-filled carbon nanotubes, tin, germanium, etc., are currently being explored as anode materials for the next generation LIBs. | |

| On electrolyte: Electrolytes in LIB conduct lithium ions to and fro between two electrodes. Using solid electrolytes could render high-energy battery chemistries and better safety (avoids fire hazards) when compared to the conventionally used liquid electrolytes. However, achieving the optimal combination of high lithium-ion conductivity and a broad electrochemical window is a challenge. Also, reduction of interfacial resistance between the solid electrolyte and lithium based anodes also poses a formidable challenge3. Nanostructuring of solid electrolytes has proven to improve the lithium ion conductivity, for example, when the conventional bulk lithium thiophosphate electrolyte was made nanoporous, it could conduct lithium ions 1000 times faster4. | |

|

|

|

| Another example is the nanostructured polymer electrolyte (NPE), which ensures safety. Main advantage of using this benign electrolyte is that it allows the use of lithium metal as anodes (instead of carbon based anodes) and contribute to the increase of energy density of the battery5. | |

| On improving the performance of LIBs | |

| The performance of the LIB is typically measured by its power and energy stored per unit mass or unit volume. The power density of the LIBs can be increased but often at an expense of energy density5. | |

| In order to achieve high power density as well as energy density, researchers are using nanotechnology to design electrodes with high surface area and short diffusion paths for ionic transport. The high surface area provides more sites for lithium ions to make contact allowing greater power density and faster discharging and recharging. | |

| Another important parameter known as rate capability, indicates the maximum current output the LIB can provide and it plays an important role in deciding life-cycle of the LIB. In general, higher the rate capability, greater is the power density and longer the cycle-life. | |

| Continue to next page (2 of 3) | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|