| Posted: Apr 24, 2012 | |

Novel electrochemical sensing platform based on graphene encrusted 3D microstructures |

|

| (Nanowerk Spotlight) Graphene with its distinctive band structure and unique physiochemical properties – such as exceptionally low intrinsic electrical resistivity, high surface area, rapid electrode kinetics and good mechanical properties – is considered an attractive material for analytical electrochemistry. However, one of the key technical challenges for the use of graphene as functional material in device applications is the integration of nanoscale graphene onto micro- or millimeter sized sensing platforms. | |

| With a new methodology, our team from Florida International University (FIU) was able to integrate graphene onto three-dimensional (3D) carbon microstructure arrays with good uniformity and controllable morphology. | |

| To take advantage of the potential merits such as very large surface areas and enhanced chemical functionalities of integrating graphene onto 3D microelectrodes, it is of interest to develop new facile approaches to conformally coat graphene onto complex 3D microstructures. Traditional techniques capable of depositing nanomaterials on 3D microstructures such as atomic layer deposition (ALD), electrodeposition, electrophoretic deposition, and modified spin coating suffer from inherently low throughput, the need for electrically conductive substrates – in the case of electrodeposition and electrophoretic deposition – and limitation in the materials that can be deposited. | |

|

|

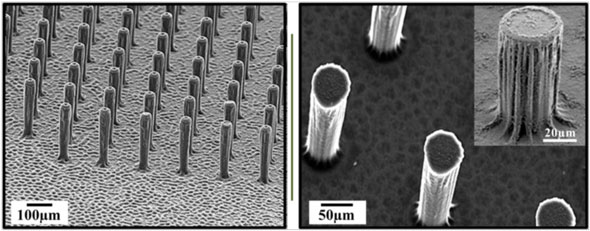

| Scanning electron microscope image of three-dimensional graphene encrusted carbon micropillar arrays. (Chunlei Wang group, Florida International University) | |

| Our goal was to apply a spray deposition technique to conformally coat graphene onto pre-patterned high aspect ratio 3D microstructures, with precise thickness and the ability to control the morphology. | |

| In the March 16, 2012 online edition of Nanoscale ("Three-Dimensional Graphene Nanosheets Encrusted Carbon Micropillar Arrays for Electrochemical Sensing"), we report, for the first time, conformal coating of graphene on 3D complex microstructures using an electrostatic spray deposition (ESD) technique. | |

| Essentially, ESD is a spray coating technique developed by Harold Ransburg in the late 1940s for spray-painting cars. In this technique, the precursor solution is atomized into an aerosol and precisely directed onto a heated substrate by high electric potential applied between the spray nozzle and the substrate. Droplets produced by electrospraying are highly charged, thereby preventing their coagulation and promoting self-dispersion. | |

| This versatile technique already has been successfully applied for the deposition of carbon nanotubes, carbon nanospheres and different metal oxide materials. | |

| In our work, we conducted a thorough study to investigate the relationship between the graphene film morphology and the ESD deposition parameters. We found that the morphology of the graphene film deposited is largely influenced by the processing conditions employed during deposition such as solution flow rate, substrate temperature and nozzle to substrate distance. | |

| "In order to demonstrate the feasibility of 3D graphene/carbon microstructure arrays for electrochemical sensing, we constructed a hydrogen peroxide detection system," explains Chunlei Wang, Associate Professor at the Department of Mechanical and Materials Engineering at FIU. "We selected hydrogen peroxide as the target analyte due to its great importance in clinical analyses, in particular for biosensors development." | |

| The results obtained in the team's study show that a graphene/carbon micropillar array electrode has improved electrochemical activity and facilities faster electron transfer. The electrode also shows a linear response towards hydrogen peroxide over a wide range of concentration with high saturation limit. | |

| In future work, we anticipate that these graphene encrusted carbon micropillar arrays can be integrated into different electrochemical devices such as on-chip supercapacitors, microbatteries, and biosensors. In addition, the methodology is very promising as a simple approach to integrate a wide variety of functional nanomaterials onto 3D functional microelectrodes, making it attractive in the electrochemistry and biotechnology fields. | |

| By Varun Penmatsa, PhD student in Chunlei Wang's group at FIU. | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|