| Posted: Jan 14, 2008 | |

Nanotechnology pipe dreams |

|

| (Nanowerk Spotlight) If you grew up in the 80's, chances are you are familiar with the addictive game 'Pipe Dream' (play it online here but there are some much better versions for installing on your computer) in which a plumber tries to lay pipe before water flowing through the pipe can overwhelm him. | |

| Get ready to play this at the nanoscale (well, kind of). Although the possibility of connecting carbon nanotubes has been an intriguing one for nanotechnology researchers, realizing this feat had proven to be difficult. Since a carbon nanotube (CNT) is made of graphite, basically a rolled up sheet of graphene, the tubes have been believed to be hard and brittle. | |

| Therefore there was not much interest in trying to shape or form them. Scientists in Japan have taken a novel approach to this problem and indeed succeeded in shaping and connecting carbon nanotubes like water pipes. Their simple method will allow longer and multi-branched CNTs with serial junctions to be made by repeated joining, and may have uses for different applications. | |

| Not only does the bottom-up engineering of nanotube structures become possible (e.g. simply increasing their aspect ratio) but it could pave the way to an entirely new class of bottom-up-engineered nanostructures and integrated carbon nanotube devices. | |

| "We have demonstrated that a Joule heating process, and associated electro-migration effects, can be used to connect two carbon nanotubes that have the same (or similar) diameters" Dr. Kazu Suenaga explains to Nanowerk. "More generally, with the assistance of a tungsten metal particle, this technique can be used to seamlessly join any two carbon nanotubes – regardless of their diameters – to form new nanotube structures." | |

| Suenaga, who heads the Nanoscale Characterization Team at the AIST Carbon Center, and Chuanhong Jin, who is first author of a paper in Nature Nanotechnology describing the findings ("Plumbing carbon nanotubes"), manipulated the CNTs inside a transmission electron microscope under direct observation. | |

| They first split a single-walled CNT (SWCNT) by placing it across two electrodes (a tungsten tip and a palladium wire) and applying a high current. This causes the diameter midway along the length of the SWCNT to become gradually narrower und ultimately break into two. | |

| "The two capped SWCNTs may be mechanically re-contacted in a cap-to-cap geometry by moving the one mounted on the tungsten tip such that it approaches the other" says Jin. "The voltage and current are then gradually raised from zero. On reaching threshold values of 1.6 V and ∼6 µA the two SWCNTs suddenly join again into a CNT having its own unique geometry. | |

|

|

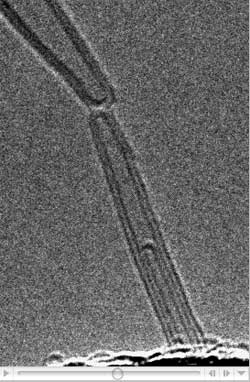

| Watch a movie of this process here: An in situ TEM movie shows the successful joining attempt on two double-walled CNTs. Each frame was recorded in 0.5 second exposure. The movie plays 2.5 times faster than the real time. | |

| Suenaga points out that the process would not have been successful without the Joule heating because the plastic deformation of carbon nanotubes requires a high activation energy. | |

| The AIST researchers considered three different geometries for joining the tubes: Cap-to-cap joining of two CNTs with the same or similar diameter; cap-to-cap joining of two CNTs with different diameters; and cap-to-wall joining of two CNTs to form a Y- or T-type junction. | |

| Cap-to-cap joining of CNTs with same diameter and origin was successful in every attempt. The whole process, including breaking and joining, could be repeated many times on the same SWNT (they tried up to seven times). Attempting cap-to-wall and cap-to-cap joining of CNTs with different diameters proved unsuccessful. | |

| "By simply applying a voltage and introducing a current, two CNTs with the same or similar diameter can indeed be joined, but it seems to be intrinsically difficult to join two CNTs with completely different diameters" says Jin. | |

| It appears that the different chiralities of the nanotubes are causing a matching problem at the atomic level. (CNTs made from the electrical breakdown of a single nanotube are likely to have the same chirality, but two CNTs having different diameters should have different chiralities.) | |

| Suenaga and Jin found a way around this problem: "In order to overcome this drawback, we have inserted tungsten particles to create a joint with two CNTs of completely different diameters by intentionally reducing the energy barrier of Stone-Wales defect migrations and/or catalyzing the graphene network re-arrangement" says Jin. | |

|

|

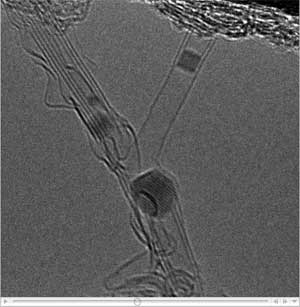

| Watch a movie of a y-junction formation here: An in situ TEM movie shows the tungsten-assist joining of two CNTs with different diameters to form a Y-type junction. Each frame was recorded in 0.5 second exposure. The movie plays 5 times faster than the real time. | |

| Tungsten helps carbon atoms to "graphitize" – to arrange themselves into ordered structures such as in graphite. During the annealing process the two tubes begin to share an additional graphitic layer that should have been created through the tungsten particle from the surrounding carbon atoms. | |

| "We found that annealing under a higher current and moving the tungsten particle back and forth – by changing the polarity of the input voltage – has further improved the quality of the junction" says Jin. "Finally, a new CNT is fabricated and a seamless connection between the two nanotubes having completely different diameters has been successfully achieved." | |

| "We would like to clarify two important points that can be deduced from the experiments" says Suenaga. "First, both the ordered lattice fringes and the regular crystalline shape demonstrate that the tungsten particle remains in the solid state during the whole process, although its shape often changes instantaneously (the so-called quasi solid state). Second, the graphite shells can continuously dissolve into the tungsten particle during migration under high current flux. Lattice fringes consistent with tungsten carbide are often observed in the particles." | |

| He also points out that these results could have positive implications for device applications of CNTs such as for instance field-effect transistors. "If they break down during operation, the nanotubes could be mended by application of a continuous inducing current." | |

| The serial joining of carbon nanotubes in a controlled manner offers a promising approach for the bottom-up engineering of nanotube structures. For example, connecting a semiconducting nanotube and a metallic nanotube to build a nano-diode is now definitely achievable. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.