| Sep 30, 2021 | |

New strategy achieves electric insulator polyethylene with high thermal conductivity and dielectric strength |

|

| (Nanowerk Spotlight) Polymers are ideal for energy storage for transportation due to their light weight, scalability, low-cost manufacturing, and high dielectric strength. Dielectrics are materials that do not conduct electricity, but when exposed to an electric field, store electricity. They can release energy very quickly to satisfy engine start-ups or to convert the direct current in batteries to the alternating current needed to drive motors. | |

| Polymer dielectrics are widely used as an insulating material in advanced electronics and electric power systems that require operation at high temperatures and high breakdown conditions. | |

| The miniaturization and higher power of modern electronics generate lots of heat, which needs to be dissipated quickly to avoid device malfunction or breakdown. This increased heat also leads to the temperature rise of insulating materials, which gradually causes the loss of dielectric performance. | |

| This situation required the development of insulating materials with high thermal conductivity to greatly reduce the operating temperature of the electrical equipment. Simply using thicker insulation materials to accommodate the higher voltages is no longer an option with greatly miniaturized electronics since this can't meet the required space and weight parameters anymore. | |

| "Unfortunately, the way that electric and thermal transport parameters in dielectrics are correlated via the Wiedemann–Franz law, works against the occurrence of thermally-conductive polymer electric insulators,", Shenqiang Ren, a Professor in the Department of Mechanical and Aerospace Engineering, and Department of Chemistry, at the University at Buffalo (UB), tells Nanowerk. "Avoiding this bottleneck requires rational design not only of polymer material itself (polar vs. non-polar) but also of hierarchical molecular structures at multiple length scales (crystalline lattice strain vs. chain alignment) that can respond in the desired way to extreme working factors in real time." | |

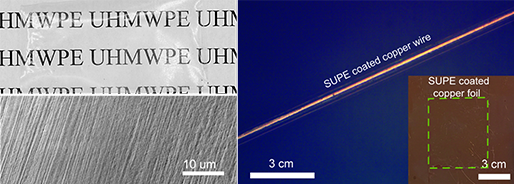

| Ren, Zheng Li, and his team at UB, now report a new strategy to achieve high thermal conductive electric insulator polyethylene with high dielectric constant and strength. In this work, published in Science Advances ("Solution-shearing of dielectric polymer with high thermal conductivity and electric insulation"), the researchers describe solution gel-sheared ultrahigh molecular weight polyethylene (SUPE) to become an enabling electric insulating material measured by an outstanding in-plane thermal conductivity of 10.74 W m-1 K-1, and an average dielectric constant of 4.1. | |

| Compared with standard polymer dielectrics, the SUPE transparent thin-films outstanding thermal conductivity is 20 times higher than non-strained polyethylene, and their average dielectric constant is about 1.8 times higher than non-strained polyethylene. With this material, the heat flux from power electronic systems can be dissipated instantly, which will improve the achievable power density and efficiency. | |

|

|

| The solution gel-sheared transparent and strained ultrahigh molecular weight polymer films with the chain alignment of the shearing direction. (Image: Ren group, University at Buffalo) | |

| "We ascribe the dramatically improved dielectric properties and thermal conductivities in the solution-gel sheared SUPE material to the alignment and close packing of ultrahigh molecular weight crystalline chains, facilitating the formation of a large number of separated nano-capacitor arrays with high k and high resistivity," Dr. Jian Yu, a materials engineer at DEVCOM Army Research Laboratory, explains. | |

| Due to its high thermal conductivity and high breakdown voltage, this novel SUPE polymer electric insulator is a promising electrical insulator material for today's high-power electric systems and advanced electronics. Potential applications include polymer insulators for advanced electronics with thermal management, such as conductors, circuit boards, and printable electronics. | |

| The team's next step is to explore the application of SUPE on electronic devices or electronics demanding thermal management, such as high-power printable electronics, the sheath jacket for electric wires, 5G electronics, and cables. | |

| "As we have demonstrated in our study, our energy-efficient polymer dielectric material possesses superior thermal conducting, mechanical and dielectric durability, and reliability across a broad temperature and frequency range," Ren concludes. "These findings overcome two important hurdles in high-temperature electric-insulation polymer materials by rationally designing the hierarchical structure through solution gel-shearing and lattice strains and by manufacturing lightweight, flexible polymers that can be shaped into intricate configurations for safe applications in high power electronics and flexible advanced electric systems." The funding to this work was provided by the U.S. Army Research Laboratory. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|