Showing Spotlights 2457 - 2464 of 2783 in category All (newest first):

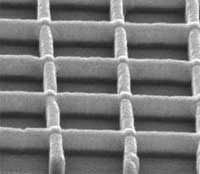

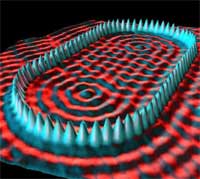

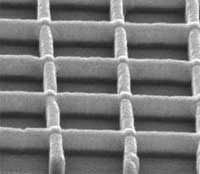

OLEDs - organic light-emitting diodes - are full of promise for a range of practical applications not too far into the future. Today, OLEDs are used in small electronic device displays in mobile phones, MP3 players, digital cameras, etc. With more efficient and cheaper OLED technologies we soon will see ultraflat, very bright and power-saving OLED televisions, windows that could be used as light source at night, and large-scale organic solar cells. In contrast to regular LEDs, the emissive electroluminescent layer of an OLED consists of a thin-film of organic compounds. What makes OLEDs so attractive is that they do not require a backlight to function. Thus they draw far less power and, when powered from a battery, can operate longer on the same charge. OLED devices can be made thinner and lighter than comparable LED devices. Last but not least, OLEDs can be printed onto almost any substrate with inkjet printer technology, making new applications like displays embedded in clothes or roll-up displays possible. Unfortunately there are also drawbacks to this technology. Apart from its currently high manufacturing cost, the major problem is device degradation and the limited lifetime of organic materials. In particular, the most commonly used material for the anode, ITO (indium tin oxide), is a less than optimal material for future high-performance OLEDs. New research indicates that nanoimprinted semitransparent metal electrodes, replacing ITO electrodes, are an attractive and potentially practical solution for OLEDs and other organic devices.

OLEDs - organic light-emitting diodes - are full of promise for a range of practical applications not too far into the future. Today, OLEDs are used in small electronic device displays in mobile phones, MP3 players, digital cameras, etc. With more efficient and cheaper OLED technologies we soon will see ultraflat, very bright and power-saving OLED televisions, windows that could be used as light source at night, and large-scale organic solar cells. In contrast to regular LEDs, the emissive electroluminescent layer of an OLED consists of a thin-film of organic compounds. What makes OLEDs so attractive is that they do not require a backlight to function. Thus they draw far less power and, when powered from a battery, can operate longer on the same charge. OLED devices can be made thinner and lighter than comparable LED devices. Last but not least, OLEDs can be printed onto almost any substrate with inkjet printer technology, making new applications like displays embedded in clothes or roll-up displays possible. Unfortunately there are also drawbacks to this technology. Apart from its currently high manufacturing cost, the major problem is device degradation and the limited lifetime of organic materials. In particular, the most commonly used material for the anode, ITO (indium tin oxide), is a less than optimal material for future high-performance OLEDs. New research indicates that nanoimprinted semitransparent metal electrodes, replacing ITO electrodes, are an attractive and potentially practical solution for OLEDs and other organic devices.

Jun 7th, 2007

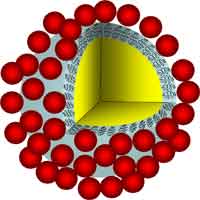

Scientists involved in cancer research are showing a lot of interest in carbon nanotubes (CNTs) to be used in basically three cancer-fighting areas. CNTs are being developed as targeted delivery vehicles for anticancer drugs right into cancer cells - think of really, really tiny injection needles. They are also used as the therapeutic agent itself; there is research that shows that CNTs can act as nanoscale bombs that literally blow apart a cancer cell. A third area of application is using CNTs as imaging agents.

Scientists involved in cancer research are showing a lot of interest in carbon nanotubes (CNTs) to be used in basically three cancer-fighting areas. CNTs are being developed as targeted delivery vehicles for anticancer drugs right into cancer cells - think of really, really tiny injection needles. They are also used as the therapeutic agent itself; there is research that shows that CNTs can act as nanoscale bombs that literally blow apart a cancer cell. A third area of application is using CNTs as imaging agents.

Jun 6th, 2007

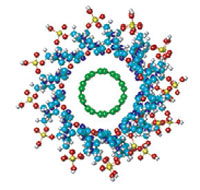

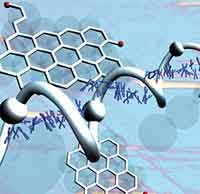

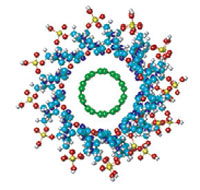

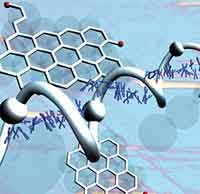

To achieve the full benefits of the amazing properties of carbon nanotubes (CNTs) researchers are exploring all kinds of CNT composite materials. Material engineers are interested because this will lead to lighter,stronger and tougher materials. Another fascinating area involves CNT/polymer composite structures that will lead to a vast range of improved and novel applications, from antistatic and EMI shielding to more efficient fuel and solar cells, to nanoelectronic devices. One particular area of CNT/polymer composites is dealing with DNA-CNTs hybrids. Although researchers expect a plethora of new applications, the fact that even the formation mechanism of these complexes is not yet clear shows how early in the game this research still is. This might be due to the fact that in spite of the quite large number of experimental investigations on the interaction between DNA and CNTs, the number of theoretical studies is limited. Researchers in Germany now present, for the first time, the results of a systematic quantum mechanical modeling of the stability and the electronic properties of complexes based on single-walled carbon nanotubes, which are helically wrapped by DNA molecules.

To achieve the full benefits of the amazing properties of carbon nanotubes (CNTs) researchers are exploring all kinds of CNT composite materials. Material engineers are interested because this will lead to lighter,stronger and tougher materials. Another fascinating area involves CNT/polymer composite structures that will lead to a vast range of improved and novel applications, from antistatic and EMI shielding to more efficient fuel and solar cells, to nanoelectronic devices. One particular area of CNT/polymer composites is dealing with DNA-CNTs hybrids. Although researchers expect a plethora of new applications, the fact that even the formation mechanism of these complexes is not yet clear shows how early in the game this research still is. This might be due to the fact that in spite of the quite large number of experimental investigations on the interaction between DNA and CNTs, the number of theoretical studies is limited. Researchers in Germany now present, for the first time, the results of a systematic quantum mechanical modeling of the stability and the electronic properties of complexes based on single-walled carbon nanotubes, which are helically wrapped by DNA molecules.

Jun 4th, 2007

Diesel-burning engines are a major contributor to environmental pollution. They emit a mixture of gases and fine particles that contain some 40, mostly toxic chemicals, including benzene, butadiene, dioxin and mercury compounds. Diesel exhaust is listed as a known or probable human carcinogen by several state and federal agencies in the United States. Wouldn't it be nice if we could render diesel soot harmless before it gets released into the environment? Wouldn't it even be nicer if we could use this soot to manufacture something useful? Japanese scientists have come up not only with a unique technique for effectively collecting diesel soot but also a method for using this soot as a precursor for the production of single-walled carbon nanotubes. How is that as a practical example for green nanotechnology?

Diesel-burning engines are a major contributor to environmental pollution. They emit a mixture of gases and fine particles that contain some 40, mostly toxic chemicals, including benzene, butadiene, dioxin and mercury compounds. Diesel exhaust is listed as a known or probable human carcinogen by several state and federal agencies in the United States. Wouldn't it be nice if we could render diesel soot harmless before it gets released into the environment? Wouldn't it even be nicer if we could use this soot to manufacture something useful? Japanese scientists have come up not only with a unique technique for effectively collecting diesel soot but also a method for using this soot as a precursor for the production of single-walled carbon nanotubes. How is that as a practical example for green nanotechnology?

May 30th, 2007

One of the problems nanoscientists encounter in their forays into the nanoworld is the issue of accurate temperature measurement. Ever since Galileo Galilei invented a rudimentary water thermometer in 1593, accurate temperature measurement has been a challenging research topic and thermosensing technologies have become a field in their own right. Now, that technology has reached the nanoscale, temperature gradients are becoming essential in areas such as thermoelectricity, nanofluidics, design of computer chips, or hyperthermal treatment of cancer. Currently there is no established method how to measure the temperature gradients at the nanoscale. Most of today's probes are traditional bulk probes, the kind that gets inserted into a sample and measures the temperature. Liquid crystal films which change colors depending on temperature also have at least microscale thickness and lateral dimensions. A recent review addresses these issues and gives an overview of current and future developments for nanoscale temperature measurement technologies.

One of the problems nanoscientists encounter in their forays into the nanoworld is the issue of accurate temperature measurement. Ever since Galileo Galilei invented a rudimentary water thermometer in 1593, accurate temperature measurement has been a challenging research topic and thermosensing technologies have become a field in their own right. Now, that technology has reached the nanoscale, temperature gradients are becoming essential in areas such as thermoelectricity, nanofluidics, design of computer chips, or hyperthermal treatment of cancer. Currently there is no established method how to measure the temperature gradients at the nanoscale. Most of today's probes are traditional bulk probes, the kind that gets inserted into a sample and measures the temperature. Liquid crystal films which change colors depending on temperature also have at least microscale thickness and lateral dimensions. A recent review addresses these issues and gives an overview of current and future developments for nanoscale temperature measurement technologies.

Jun 1st, 2007

One of the most common methods of film manufacture is Blown Film Extrusion. The process, by which most commodity and specialized plastic films are made for the packaging industry, involves extrusion of a plastic through a circular die, followed by "bubble-like" expansion. The resulting thin tubular film can be used directly, or slit to form a flat film. Nanoscientists now have found a way to use this very common and efficient industrial technology to potentially solve the problem of fabricating large-area nanocomposite films. Currently, the problems with making thin film assemblies are either the production cost of using complex techniques like wet spinning or the unsatisfactory results of unevenly distributed and lumping nanoparticles within the film. The new bubble film technique results in well-aligned and controlled-density nanowire and carbon nanotubes (CNTs) films over large areas. These findings could finally open the door to affordable and reliable large-scale assembly of nanostructures.

One of the most common methods of film manufacture is Blown Film Extrusion. The process, by which most commodity and specialized plastic films are made for the packaging industry, involves extrusion of a plastic through a circular die, followed by "bubble-like" expansion. The resulting thin tubular film can be used directly, or slit to form a flat film. Nanoscientists now have found a way to use this very common and efficient industrial technology to potentially solve the problem of fabricating large-area nanocomposite films. Currently, the problems with making thin film assemblies are either the production cost of using complex techniques like wet spinning or the unsatisfactory results of unevenly distributed and lumping nanoparticles within the film. The new bubble film technique results in well-aligned and controlled-density nanowire and carbon nanotubes (CNTs) films over large areas. These findings could finally open the door to affordable and reliable large-scale assembly of nanostructures.

May 31st, 2007

The human body so far is the ultimate 'wet computer' - a highly efficient, biomolecule-based information processor that relies on chemical, optical and electrical signals to operate. Researchers are trying various routes to mimic some of the body's approaches to computing. Prominent among them is DNA computing, a form of computing which uses DNA and molecular biology instead of the traditional silicon-based computer technologies (see our Spotlight: "Molecular automaton plays tic-tac-toe"). Not limited to DNA, "gooware" computer scientists attempt to exploit the computational capabilities of molecules. In doing so, they expect to realize faster (massively parallel), smaller (nanoscale), and cost efficient (energy-saving) information processing devices that are very distinct from today's silicon-based computers.

The human body so far is the ultimate 'wet computer' - a highly efficient, biomolecule-based information processor that relies on chemical, optical and electrical signals to operate. Researchers are trying various routes to mimic some of the body's approaches to computing. Prominent among them is DNA computing, a form of computing which uses DNA and molecular biology instead of the traditional silicon-based computer technologies (see our Spotlight: "Molecular automaton plays tic-tac-toe"). Not limited to DNA, "gooware" computer scientists attempt to exploit the computational capabilities of molecules. In doing so, they expect to realize faster (massively parallel), smaller (nanoscale), and cost efficient (energy-saving) information processing devices that are very distinct from today's silicon-based computers.

May 29th, 2007

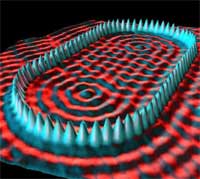

It has been 25 years since the scanning tunneling microscope (STM) was invented, followed four years later by the atomic force microscope, and that's when nanoscience and nanotechnology really started to take off. Various forms of scanning probe microscopes based on these discoveries are essential for many areas of today's research. Scanning probe techniques have become the workhorse of nanoscience and nanotechnology research. Given the 25-year development timeframe, it is surprising that even today there is no generally accepted standard for scanning probe microscopy (SPM). There is no unified SPM terminology, nor is there a standard for data management and treatment, making access and processing of SPM data collected by different types of instruments an error-prone exercise. SPM standardization has only recently begun as part of an effort by the International Organization for Standardization (ISO) the largest developer of industrial standards. Meanwhile the development of SPM instruments and analysis software continues, increasing the already large family of scanning probe microscopy.

It has been 25 years since the scanning tunneling microscope (STM) was invented, followed four years later by the atomic force microscope, and that's when nanoscience and nanotechnology really started to take off. Various forms of scanning probe microscopes based on these discoveries are essential for many areas of today's research. Scanning probe techniques have become the workhorse of nanoscience and nanotechnology research. Given the 25-year development timeframe, it is surprising that even today there is no generally accepted standard for scanning probe microscopy (SPM). There is no unified SPM terminology, nor is there a standard for data management and treatment, making access and processing of SPM data collected by different types of instruments an error-prone exercise. SPM standardization has only recently begun as part of an effort by the International Organization for Standardization (ISO) the largest developer of industrial standards. Meanwhile the development of SPM instruments and analysis software continues, increasing the already large family of scanning probe microscopy.

May 25th, 2007

OLEDs - organic light-emitting diodes - are full of promise for a range of practical applications not too far into the future. Today, OLEDs are used in small electronic device displays in mobile phones, MP3 players, digital cameras, etc. With more efficient and cheaper OLED technologies we soon will see ultraflat, very bright and power-saving OLED televisions, windows that could be used as light source at night, and large-scale organic solar cells. In contrast to regular LEDs, the emissive electroluminescent layer of an OLED consists of a thin-film of organic compounds. What makes OLEDs so attractive is that they do not require a backlight to function. Thus they draw far less power and, when powered from a battery, can operate longer on the same charge. OLED devices can be made thinner and lighter than comparable LED devices. Last but not least, OLEDs can be printed onto almost any substrate with inkjet printer technology, making new applications like displays embedded in clothes or roll-up displays possible. Unfortunately there are also drawbacks to this technology. Apart from its currently high manufacturing cost, the major problem is device degradation and the limited lifetime of organic materials. In particular, the most commonly used material for the anode, ITO (indium tin oxide), is a less than optimal material for future high-performance OLEDs. New research indicates that nanoimprinted semitransparent metal electrodes, replacing ITO electrodes, are an attractive and potentially practical solution for OLEDs and other organic devices.

OLEDs - organic light-emitting diodes - are full of promise for a range of practical applications not too far into the future. Today, OLEDs are used in small electronic device displays in mobile phones, MP3 players, digital cameras, etc. With more efficient and cheaper OLED technologies we soon will see ultraflat, very bright and power-saving OLED televisions, windows that could be used as light source at night, and large-scale organic solar cells. In contrast to regular LEDs, the emissive electroluminescent layer of an OLED consists of a thin-film of organic compounds. What makes OLEDs so attractive is that they do not require a backlight to function. Thus they draw far less power and, when powered from a battery, can operate longer on the same charge. OLED devices can be made thinner and lighter than comparable LED devices. Last but not least, OLEDs can be printed onto almost any substrate with inkjet printer technology, making new applications like displays embedded in clothes or roll-up displays possible. Unfortunately there are also drawbacks to this technology. Apart from its currently high manufacturing cost, the major problem is device degradation and the limited lifetime of organic materials. In particular, the most commonly used material for the anode, ITO (indium tin oxide), is a less than optimal material for future high-performance OLEDs. New research indicates that nanoimprinted semitransparent metal electrodes, replacing ITO electrodes, are an attractive and potentially practical solution for OLEDs and other organic devices.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed