Showing Spotlights 561 - 568 of 643 in category All (newest first):

The promise of revolutionary bottom-up nanotechnology is based on a vision of molecular assembly technologies where nanoscale materials and structures self-assemble to microscale structures and finally to macroscopic devices and products. We are a long way from realizing this vision but researchers are busily laying the foundation for the things to come. Assembling nanoscopic components into macroscopic materials has been an appealing goal but one of the enormous difficulties lies in bridging approximately six orders of magnitude that separate the nanoscale from the macroscopic world. New research at Northwestern University in the U.S. helps to overcomes this difficulty by dividing the assembly process into two manageable sub-steps. First, nanoparticles are assembled into larger, 100 nm-size, spherical building blocks, which are both deformable and "sticky" towards one another. Once assembled, these components "glue" together like pieces of clay to give millimeter or even centimeter-sized structures. The novelty of this technique is both the hierarchical assembly approach (i.e., atoms to nanoparticles to supraspheres to macroscopic materials) and the resulting "soft" structures, which contrast with previously reported hard and brittle nanoparticles assemblies/crystals. This research takes a further step in making nanoscale discoveries relevant to our everyday - macroscopic - world.

The promise of revolutionary bottom-up nanotechnology is based on a vision of molecular assembly technologies where nanoscale materials and structures self-assemble to microscale structures and finally to macroscopic devices and products. We are a long way from realizing this vision but researchers are busily laying the foundation for the things to come. Assembling nanoscopic components into macroscopic materials has been an appealing goal but one of the enormous difficulties lies in bridging approximately six orders of magnitude that separate the nanoscale from the macroscopic world. New research at Northwestern University in the U.S. helps to overcomes this difficulty by dividing the assembly process into two manageable sub-steps. First, nanoparticles are assembled into larger, 100 nm-size, spherical building blocks, which are both deformable and "sticky" towards one another. Once assembled, these components "glue" together like pieces of clay to give millimeter or even centimeter-sized structures. The novelty of this technique is both the hierarchical assembly approach (i.e., atoms to nanoparticles to supraspheres to macroscopic materials) and the resulting "soft" structures, which contrast with previously reported hard and brittle nanoparticles assemblies/crystals. This research takes a further step in making nanoscale discoveries relevant to our everyday - macroscopic - world.

Apr 25th, 2007

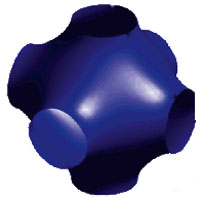

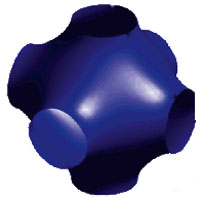

Self assembled structures from colloidal particles have many applications in biology, as chemical sensors and as photonic crystals. The control of shape and valency of the colloidal particle is very important since it will determine the 3D lattices of the assembled structure. There have been several prior effort to fabricating particles with complex shapes. Most particles with anisotropic shape are from the simple assembly of spheres or the modification of spherical particles. Interference lithography is one of the few techniques which can provide direct and systematic control over symmetry and volume fraction of the 3D structure. It involves the simple creation of interference patterns in a photoresist systems and subsequent pinch off of the parent structure through a drying process. Researchers at MIT have now presented a new facile and high-yield route for the fabrication of highly nonspherical complex multivalent nanoparticles. This technique exploits the ability of holographic interference lithography to control network topology. These research results could lay the groundwork for establishing and demonstrating control over particle shape in colloidal nanoparticles.

Self assembled structures from colloidal particles have many applications in biology, as chemical sensors and as photonic crystals. The control of shape and valency of the colloidal particle is very important since it will determine the 3D lattices of the assembled structure. There have been several prior effort to fabricating particles with complex shapes. Most particles with anisotropic shape are from the simple assembly of spheres or the modification of spherical particles. Interference lithography is one of the few techniques which can provide direct and systematic control over symmetry and volume fraction of the 3D structure. It involves the simple creation of interference patterns in a photoresist systems and subsequent pinch off of the parent structure through a drying process. Researchers at MIT have now presented a new facile and high-yield route for the fabrication of highly nonspherical complex multivalent nanoparticles. This technique exploits the ability of holographic interference lithography to control network topology. These research results could lay the groundwork for establishing and demonstrating control over particle shape in colloidal nanoparticles.

Apr 17th, 2007

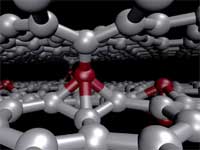

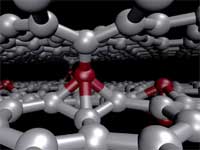

Research into the subject of radiation damage in graphite began in the early 1940s as a part of the development of nuclear weapons and nuclear power. Some designs of nuclear power reactors, such as the Chernobyl reactors, use graphite as moderator (the material which slows down the neutrons released from fission so that they cause more fission). The damage to the graphite moderators caused by radiation has been one of the major concerns of the nuclear power industry and radiation defects, i.e. structural irregularities, in graphite produced upon irradiation, their structure, properties and formation mechanisms, have been subject of intense research. Several years ago, defects in carbon materials became a hot topic again but now in the context of carbon layered nanostructures, such as multiwalled and bundled carbon nanotubes, which closely resemble graphite in their structure. The formation of irradiation-induced defects in graphite like layered carbon nanostructures, multiwalled and bundled carbon nanotubes, nanoonions, etc. changes their mechanical and electronic properties and may even trigger dramatic structural changes. While the terms "radiation damage" and "defect" are perceived negatively by people, the nanoengineering research community is trying to make use of defect structures for the deliberate modification of carbon nanomaterials, which can eventually be used in the manufacturing of nanoelectromechanical systems (NEMS). This process is sometimes called "defect-assisted engineering."

Research into the subject of radiation damage in graphite began in the early 1940s as a part of the development of nuclear weapons and nuclear power. Some designs of nuclear power reactors, such as the Chernobyl reactors, use graphite as moderator (the material which slows down the neutrons released from fission so that they cause more fission). The damage to the graphite moderators caused by radiation has been one of the major concerns of the nuclear power industry and radiation defects, i.e. structural irregularities, in graphite produced upon irradiation, their structure, properties and formation mechanisms, have been subject of intense research. Several years ago, defects in carbon materials became a hot topic again but now in the context of carbon layered nanostructures, such as multiwalled and bundled carbon nanotubes, which closely resemble graphite in their structure. The formation of irradiation-induced defects in graphite like layered carbon nanostructures, multiwalled and bundled carbon nanotubes, nanoonions, etc. changes their mechanical and electronic properties and may even trigger dramatic structural changes. While the terms "radiation damage" and "defect" are perceived negatively by people, the nanoengineering research community is trying to make use of defect structures for the deliberate modification of carbon nanomaterials, which can eventually be used in the manufacturing of nanoelectromechanical systems (NEMS). This process is sometimes called "defect-assisted engineering."

Apr 13th, 2007

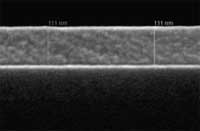

Super-tough materials with exceptional mechanical properties are in critical need for applications under extreme conditions such as jet engines, power turbines, catalytic heat exchangers, military armors, aircrafts, and spacecrafts. Researchers involved in improving man-made composite materials are trying to understand how some of the amazing high-performance materials found in Nature can be copied or even improved upon. Nature has evolved complex bottom-up methods for fabricating ordered nanostructured materials that often have extraordinary mechanical strength and toughness. One of the best examples is nacre, the pearly internal layer of many mollusc shells. It has evolved through millions of years to a level of optimization currently achieved in very few engineered composites. In a novel approach, scientists have prepared a high-performing nanocomposite material that takes advantage of two different exceptional natural materials - layered nacre and the marine adhesive of mussels. The resulting nanostructured composite film exhibits high strength exceeding that of even nacre.

Super-tough materials with exceptional mechanical properties are in critical need for applications under extreme conditions such as jet engines, power turbines, catalytic heat exchangers, military armors, aircrafts, and spacecrafts. Researchers involved in improving man-made composite materials are trying to understand how some of the amazing high-performance materials found in Nature can be copied or even improved upon. Nature has evolved complex bottom-up methods for fabricating ordered nanostructured materials that often have extraordinary mechanical strength and toughness. One of the best examples is nacre, the pearly internal layer of many mollusc shells. It has evolved through millions of years to a level of optimization currently achieved in very few engineered composites. In a novel approach, scientists have prepared a high-performing nanocomposite material that takes advantage of two different exceptional natural materials - layered nacre and the marine adhesive of mussels. The resulting nanostructured composite film exhibits high strength exceeding that of even nacre.

Apr 3rd, 2007

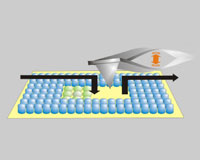

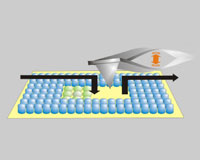

Proteins are very specific about which other proteins or biochemicals they will interact with and therefore are of great use for biosensing applications. For instance, if a malignant cancer develops in the human body, the cancer cells produce certain types of proteins. Identifying such proteins enables early detection of cancer. One of the goals of nanobiotechnology is to develop protein chips that are sensitively responsive to a very tiny amount of specific proteins in order to enable such early stage diagnosis. For example, a protein that is known to bind to a protein produced by a cancer cell could be attached to a biochip. If this particular cancer cell protein were present in a sample passed over the chip, it would bind to the protein on the chip, causing a detectable change in the electrical signal passing through the chip. This change in the electrical signal would be registered by the device, confirming the presence of the protein in the sample. While this sounds very promising for the future of diagnostic systems, with the promise of protein chips capable of single-molecule resolution, the controlled assembly of proteins into bioactive nanostructures still is a key challenge in nanobiotechnology. Researchers in Germany took a further step towards this goal by developing a native protein nanolithography technique that allows for the nanostructured assembly of even fragile proteins.

Proteins are very specific about which other proteins or biochemicals they will interact with and therefore are of great use for biosensing applications. For instance, if a malignant cancer develops in the human body, the cancer cells produce certain types of proteins. Identifying such proteins enables early detection of cancer. One of the goals of nanobiotechnology is to develop protein chips that are sensitively responsive to a very tiny amount of specific proteins in order to enable such early stage diagnosis. For example, a protein that is known to bind to a protein produced by a cancer cell could be attached to a biochip. If this particular cancer cell protein were present in a sample passed over the chip, it would bind to the protein on the chip, causing a detectable change in the electrical signal passing through the chip. This change in the electrical signal would be registered by the device, confirming the presence of the protein in the sample. While this sounds very promising for the future of diagnostic systems, with the promise of protein chips capable of single-molecule resolution, the controlled assembly of proteins into bioactive nanostructures still is a key challenge in nanobiotechnology. Researchers in Germany took a further step towards this goal by developing a native protein nanolithography technique that allows for the nanostructured assembly of even fragile proteins.

Apr 2nd, 2007

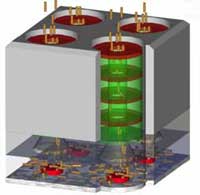

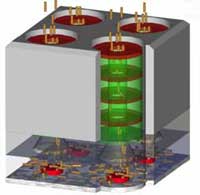

Most of today's rocket engines rely on chemical propulsion. All current spacecraft use some form of chemical rocket for launch and most use them for attitude control as well (the control of the angular position and rotation of the spacecraft, either relative to the object that it is orbiting, or relative to the celestial sphere). Real rocket scientists though are actively researching new forms of space propulsion systems. One heavily researched area is electric propulsion (EP) that includes field emission electric propulsion (FEEP), colloid thrusters and other versions of field emission thrusters (FETs). EP systems significantly reduce the required propellant mass compared to conventional chemical rockets, allowing to increase the payload capacity or decrease the launch mass. EP has been successfully demonstrated as primary propulsion systems for NASA's Deep Space 1, Japan's HAYABUSA, and ESA's SMART11 missions. A new EP concept proposes to utilize electrostatically charged and accelerated nanoparticles as propellant. Millions of micron-sized nanoparticle thrusters would fit on one square centimeter, allowing the fabrication of highly scaleable thruster arrays.

Most of today's rocket engines rely on chemical propulsion. All current spacecraft use some form of chemical rocket for launch and most use them for attitude control as well (the control of the angular position and rotation of the spacecraft, either relative to the object that it is orbiting, or relative to the celestial sphere). Real rocket scientists though are actively researching new forms of space propulsion systems. One heavily researched area is electric propulsion (EP) that includes field emission electric propulsion (FEEP), colloid thrusters and other versions of field emission thrusters (FETs). EP systems significantly reduce the required propellant mass compared to conventional chemical rockets, allowing to increase the payload capacity or decrease the launch mass. EP has been successfully demonstrated as primary propulsion systems for NASA's Deep Space 1, Japan's HAYABUSA, and ESA's SMART11 missions. A new EP concept proposes to utilize electrostatically charged and accelerated nanoparticles as propellant. Millions of micron-sized nanoparticle thrusters would fit on one square centimeter, allowing the fabrication of highly scaleable thruster arrays.

Mar 26th, 2007

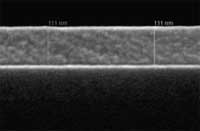

A few years ago it was discovered that the process of thermal inkjet printing can be applied to fabricate hard tissue scaffolds (such as bones) and, just recently, soft tissue with liquid biomaterials. Research is also underway to use inkjet printing for the fabrication of organic semiconductors, which, because of their low stability, will be targeted at one-time-only applications such as water purity testers. Compared to the research done with respect to organic materials, inkjet printing of inorganic materials for the formation of active devices is relatively rare. To date, only a handful of inorganic materials have been inkjet printed, primarily because of the difficulty in preparing inkjet-printable precursors. Current methods for the production of functional inorganic electronic devices are quite expensive because they require the sequential deposition, patterning, and etching of selected semiconducting, conducting, and insulating materials, involving multiple photolithography and vacuum-deposition processes. Now though, researchers have come up with a process for printable inorganic semiconductors, opening a route to the fabrication of high-performance and ultra low-cost electronics such as transparent electronics and thin film solar cells.

A few years ago it was discovered that the process of thermal inkjet printing can be applied to fabricate hard tissue scaffolds (such as bones) and, just recently, soft tissue with liquid biomaterials. Research is also underway to use inkjet printing for the fabrication of organic semiconductors, which, because of their low stability, will be targeted at one-time-only applications such as water purity testers. Compared to the research done with respect to organic materials, inkjet printing of inorganic materials for the formation of active devices is relatively rare. To date, only a handful of inorganic materials have been inkjet printed, primarily because of the difficulty in preparing inkjet-printable precursors. Current methods for the production of functional inorganic electronic devices are quite expensive because they require the sequential deposition, patterning, and etching of selected semiconducting, conducting, and insulating materials, involving multiple photolithography and vacuum-deposition processes. Now though, researchers have come up with a process for printable inorganic semiconductors, opening a route to the fabrication of high-performance and ultra low-cost electronics such as transparent electronics and thin film solar cells.

Mar 20th, 2007

Geneticists regularly use viruses as vectors to introduce genes into cells that they are studying. Viruses are also the most common carrier vehicles in gene therapy. Having been genetically altered to carry normal human DNA, they deliver the therapeutic genes to the patient's target cells. These viruses infect cells, deposit their DNA payloads, and take over the cells' machinery to produce the desirable proteins. Current trends in nanotechnology promise to take virus technology into an entirely new direction. From the viewpoint of a materials scientist, viruses can be regarded as organic nanoparticles. Their surface carries specific tools designed to cross the barriers of their host cells. The size and shape of viruses, and the number and nature of the functional groups on their surface, is precisely defined. As such, viruses are commonly used in materials science as scaffolds for covalently linked surface modifications. The powerful techniques developed by life sciences are becoming the basis of engineering approaches towards nanomaterials, opening a wide range of applications far beyond biology and medicine.

Geneticists regularly use viruses as vectors to introduce genes into cells that they are studying. Viruses are also the most common carrier vehicles in gene therapy. Having been genetically altered to carry normal human DNA, they deliver the therapeutic genes to the patient's target cells. These viruses infect cells, deposit their DNA payloads, and take over the cells' machinery to produce the desirable proteins. Current trends in nanotechnology promise to take virus technology into an entirely new direction. From the viewpoint of a materials scientist, viruses can be regarded as organic nanoparticles. Their surface carries specific tools designed to cross the barriers of their host cells. The size and shape of viruses, and the number and nature of the functional groups on their surface, is precisely defined. As such, viruses are commonly used in materials science as scaffolds for covalently linked surface modifications. The powerful techniques developed by life sciences are becoming the basis of engineering approaches towards nanomaterials, opening a wide range of applications far beyond biology and medicine.

Mar 19th, 2007

The promise of revolutionary bottom-up nanotechnology is based on a vision of molecular assembly technologies where nanoscale materials and structures self-assemble to microscale structures and finally to macroscopic devices and products. We are a long way from realizing this vision but researchers are busily laying the foundation for the things to come. Assembling nanoscopic components into macroscopic materials has been an appealing goal but one of the enormous difficulties lies in bridging approximately six orders of magnitude that separate the nanoscale from the macroscopic world. New research at Northwestern University in the U.S. helps to overcomes this difficulty by dividing the assembly process into two manageable sub-steps. First, nanoparticles are assembled into larger, 100 nm-size, spherical building blocks, which are both deformable and "sticky" towards one another. Once assembled, these components "glue" together like pieces of clay to give millimeter or even centimeter-sized structures. The novelty of this technique is both the hierarchical assembly approach (i.e., atoms to nanoparticles to supraspheres to macroscopic materials) and the resulting "soft" structures, which contrast with previously reported hard and brittle nanoparticles assemblies/crystals. This research takes a further step in making nanoscale discoveries relevant to our everyday - macroscopic - world.

The promise of revolutionary bottom-up nanotechnology is based on a vision of molecular assembly technologies where nanoscale materials and structures self-assemble to microscale structures and finally to macroscopic devices and products. We are a long way from realizing this vision but researchers are busily laying the foundation for the things to come. Assembling nanoscopic components into macroscopic materials has been an appealing goal but one of the enormous difficulties lies in bridging approximately six orders of magnitude that separate the nanoscale from the macroscopic world. New research at Northwestern University in the U.S. helps to overcomes this difficulty by dividing the assembly process into two manageable sub-steps. First, nanoparticles are assembled into larger, 100 nm-size, spherical building blocks, which are both deformable and "sticky" towards one another. Once assembled, these components "glue" together like pieces of clay to give millimeter or even centimeter-sized structures. The novelty of this technique is both the hierarchical assembly approach (i.e., atoms to nanoparticles to supraspheres to macroscopic materials) and the resulting "soft" structures, which contrast with previously reported hard and brittle nanoparticles assemblies/crystals. This research takes a further step in making nanoscale discoveries relevant to our everyday - macroscopic - world.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed