| Posted: Aug 12, 2013 | |

How squid and octopus might point the way to nanotechnology-based stealth coatings |

|

| (Nanowerk Spotlight) For a long time, scientists have been fascinated by the dramatic changes in color used by marine creatures like squids and octopuses, but they never quite understood the mechanism responsible for this. Only recently they found out that a neurotransmitter, acetylcholine, sets in motion a cascade of events that culminate in the addition of phosphate groups to a family of unique proteins called reflectins. This process allows the proteins to condense, driving the animal's color-changing process. The latest findings revealed that there is a nanoscale mechanism behind cephalopods' ability to change color. | |

| Watch this amazing video of a camouflaging octopus: | |

| Having begun to unravel the natural mechanisms behind these amazing abilities, researchers are trying to use this knowledge to make artificial camouflage coatings. New work from the lab of Alon A. Gorodetsky, Assistant Professor at the Henry Samueli School of Engineering at the University of California, Irvine, addresses the challenge of making something appear and disappear when visualized with standard infrared detection equipment. | |

| In a paper in the July 30, 2013, online edition of Advanced Materials ("Reconfigurable Infrared Camouflage Coatings from a Cephalopod Protein"), the team demonstrates graphene-templated, biomimetic camouflage coatings that possess several important advantages. | |

| "We used reflectin, a protein that is important for cephalopod structural coloration, as a functional optical material," Gorodetsky explains to Nanowerk. "We fabricated thin films from this protein, whose reflectance – and coloration – could be dynamically tuned over a range of over 600 nm and even into the infrared (in the presence of an appropriate stimulus). Our approach is environmentally friendly and compatible with a wide range of surfaces, potentially allowing many simple objects to acquire camouflage capabilities." | |

| The novelty of these findings lies in the functionality of the team's thin-films within the infrared region of the electromagnetic spectrum, roughly 700nm to 1200nm, which matches the standard imaging range of infrared visualization equipment. This region is not commonly accessible to biologically derived materials. Gorodetsky notes that reflectin's tunable optical properties compare favorably to those of artificial polymeric materials. | |

| "Given these advantages, our dynamically tunable, infrared-reflective films represent a crucial first step towards the development of reconfigurable and disposable biomimetic camouflage technologies for stealth applications," says Gorodetsky. " I can also imagine applications in energy efficient reflective coatings and biologically inspired optics." | |

| The team began their studies by developing a protocol for the production of the histidine-tagged reflectin A1 (RfA1). Experimenting with a variety of substrates and surface treatments for the reliable formation of RfA1 thin films, they achieved best results by spincasting 5 to 10 nm films of graphene oxide on glass substrates. They then spread RfA1 onto the graphene oxide-coated substrates, yielding smooth films over centimeter areas. | |

|

|

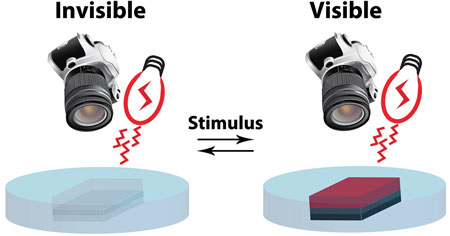

| Illustration depicting the appearance of the RfA1 film in the absence and presence of an external stimulus (acetic acid), when visualized with an infrared camera. (Reprinted with permission from Wiley-VCH Verlag) | |

| These films showed a distinct coloration, depending on their thickness. For instance, a 125 nm-thick film was blue and a 207 nm-thick film was orange. | |

| "Inspired by the dynamic optical properties of reflectin nanostructures, we sought to shift the reflectance of our RfA1 films into the infrared region of the electromagnetic spectrum," says Gorodetsky. "Given that some squid can dynamically modulate their skin reflectance across the entire visible spectrum and even out to near infrared wavelengths of ∼800 nm, we postulated that it should also be possible to tune the reflectance of our RfA1 thin films across a similar, or even larger, wavelength range. Thus, we sought conditions that would significantly increase the thickness of our RfA1 films and, consequently, shift their reflectance spectra toward the infrared." | |

| To that end, the researchers explored the response of their RfA1 coatings to a variety of chemical stimuli. They discovered that exposing the films to vapor from a concentrated acetic acid solution induced a large, reversible shift in the reflectance spectra, caused by the acid-induced swelling of the closely packed RfA1 nanoparticles in the film. | |

| "With the goal of fabricating dynamically tunable camouflage materials, which will self-reconfigure in response to an external signal, we are currently developing alternative, milder strategies for triggering coloration changes in our material," Gorodetsky describes the team's future work plans. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|