| Posted: Aug 20, 2013 | |

Inkjet printing of graphene for flexible electronics |

|

| (Nanowerk Spotlight) Graphene has a unique combination of properties that is ideal for next-generation electronics, including mechanical flexibility, high electrical conductivity, and chemical stability. Combine this with inkjet printing, already extensively demonstrated with conductive metal nanoparticle ink (see for instance: "Low-cost nanotechnology substitute for gold and silver in printable electronics"), and you get an inexpensive and scalable path for exploiting these properties in real-world technologies. | |

| Although liquid-phase graphene dispersions have been demonstrated (see: "Inkjet-printed graphene opens the door to foldable electronics"), researchers are still struggling with sophisticated inkjet printing technologies that allow efficient and reliable mass production of high-quality graphene patterns for practical applications. There are several challenges that need to be overcome: | |

|

|

|

| Recent work by researchers at the KTH Royal Institute of Technology in Sweden has addressed these issues and proposes an approach to overcome these problems. Reporting their findings in a recent issue of Advanced Materials ("Efficient Inkjet Printing of Graphene"), a team led by Max Lemme and Mikael Östling, professors at the School of Information and Communication Technology at KTH, demonstrates a mature but simple technology for inkjet printing of high-quality few-layer graphene. | |

|

|

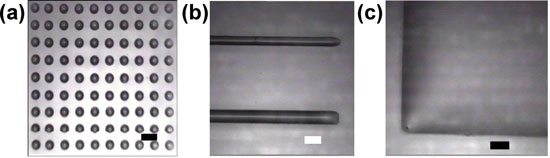

| Inkjet printed graphene patterns. a–c) Optical images of as-printed patterns on glass slides: a) droplet matrix, b) lines, and c) a film corner. (Reprinted with permission from Wiley-VCH Verlag) | |

| The approach is based on the team's previously published distillation-assisted solvent exchange technique to prepare high-concentration graphene dispersions ("A simple route towards high-concentration surfactant-free graphene dispersions"). They first exfoliate graphene from graphite flakes in dimethylformamide (DMF), and then DMF is exchanged by terpineol through distillation by virtue of the large difference between their boiling points. Therefore, graphene can be significantly concentrated if terpineol is of much lower volume than DMF. More importantly, the solvent is changed from low-viscosity and toxic DMF to high-viscosity (about 40 cP at 20° C) and environmentally-friendly terpineol. | |

| They write, though, that the disadvantages of the technique in the previous work – a short stable period (the dispersion can only be stable for about 10 hours) and severe flake aggregation during solvent evaporation – prevent the dispersions from being practical inks. "In this work, we have improved the ink formulation mainly through polymer stabilization. Before distillation, a small amount of polymer (ethyl cellulose) is added into the harvested graphene/DMF dispersion to protect the graphene flakes from agglomeration. After printing, the stabilizing poly mers can be effectively removed through a simple annealing process." | |

| The resulting graphene dispersion had a stable period of at least several weeks. The researchers point out that the inks provide well-directed and constant jetting out of all nozzles at an even velocity, which is comparable to the performance of commercially available inks. | |

| To investigate the quality of the printed graphene, the team fabricated large-area centimeter-scale graphene thin films with between 1 and 6 printing layers on glass slides. | |

| "Printed transparent conductive films attain a sheet resistance around 200 kΩ/sq at a transmittance of about 90%," they summarize their results. "Printed narrow-line resistors exhibit a resistance range from a few kΩ to several MΩ. Printed few-layer graphene thin film transistors can be modulated by the electric field effect. Printed micro-supercapacitors achieve a high specific capacitance of 0.59 mF cm-2 and a rapid frequency response time around 13 ms." | |

| The team concludes that the present technology provides an efficient and low-cost method to fabricate a variety of graphene electronic devices with good performance and is a promising alternative for future commercial applications in printed and flexible electronics. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|