| Posted: Oct 14, 2014 | |

Graphene laminate drastically changes heat conduction of plastic materials(Nanowerk Spotlight) Graphene laminate – multilayer stacks of graphene layers piled on top of each other – is a promising material for thermal coating applications. |

|

| "Graphene by itself has very high intrinsic thermal conductivity, exceeding that of diamond, which is around 2000 W/mK at room temperature," Alexander A. Balandin, Professor of Electrical Engineering and Founding Chair of Materials Science and Engineering at University of California - Riverside (UCR), explains to Nanowerk. "Depending on the size of the flake and quality, suspended graphene samples revealed the thermal conductivity values in the range from 2000 W/mK to 5000 W/mK near room temperature. When placed on substrate the thermal conductivity of graphene reduces due to phonon scattering from the rough interfaces but remains relatively high." | |

| Balandin notes that the overall values of the thermal conductivity of graphene laminate at room temperature are substantially lower (∼90 W/mK) than those measured for large suspended graphene samples. This is explained by the fact that the thermal conductivity of the laminates is limited not by the lattice dynamics of the graphene flakes but by their size, attachment to each other, and orientation with respect to the heat flux. However, the heat conduction ability of graphene laminate is still substantially better than that of plastics, which explains the practical relevance of the research. | |

|

|

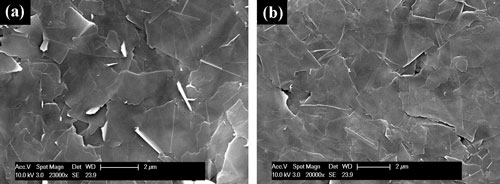

| Figure 1: Top-view scanning electronic microscopy (SEM) image of the (a) uncompressed and (b) compressed graphene laminate. Graphene laminate consists of the overlapping layers of graphene and few-layer-graphene flakes with arbitrary shapes and random in-plane orientation. Although most of the flakes are aligned along the PET substrate some of the flakes reveal vertical orientation seen as bright white areas on SEM images. The number of the misaligned vertical flakes is substantially reduced in the compressed samples. (Image courtesy of the researchers) (click on image to enlarge) | |

| In new work, researchers from UCR and the University of Manchester investigated thermal conductivity of graphene laminate films deposited on polyethylene terephthalate, commonly known as PET, substrates. They found that the compressed laminates have higher thermal conductivity for the same average flake size owing to better flake alignment. | |

| The results have been reported in a recent edition of Nano Letters ("Thermal Conductivity of Graphene Laminate"). | |

| The researchers prepared graphene laminate by deposition of an aqueous dispersion of graphene flakes on PET substrates. Graphene laminate films can be prepared in large quantities in industrial environments. | |

| They studied two types of graphene laminate – as deposited and compressed – in order to determine the physical parameters affecting the heat conduction the most. | |

|

|

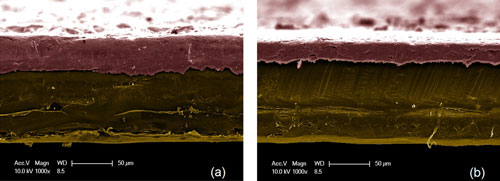

| Figure 2: Cross-sectional SEM images of the (a) uncompressed and (b) compressed graphene laminate on PET samples. The pseudo colors are used to indicate the graphene laminate (burgundy) and PET (yellow) layers. (Image courtesy of the researchers) (click on image to enlarge) | |

| "We measured the thermal conductivity of graphene laminate in the range from 40 W/mK to 90 W/mK at room temperature," says Balandin. "We found unexpectedly that the average size and the alignment of graphene flakes are more important parameters defining the heat conduction than the mass density of the graphene laminate." | |

| Interestingly, the team found that the thermal conductivity scales up linearly with the average graphene flake size in both uncompressed and compressed laminates. | |

| This means that the compressed laminates have higher thermal conductivity for the same average flake size owing to better flake alignment. | |

| Balandin points out that the team's results are important because they show a possibility of up to 600-times enhancement of the thermal conductivity of plastic materials by coating them with the thin graphene laminate films. | |

| The thermal conductivity of PET is extremely low in the range from 0.15 to 0.24 W/mK at room temperature. Other plastic materials also suffer from low thermal conductivity. The latter prevents many possible applications, which otherwise would benefit from low cost, durability and light weight of plastics. The present work demonstrates that a few micrometer-thick graphene laminate deposited on plastic films can drastically change their heat conduction properties. | |

| This means that graphene laminate coatings could substantially increase the range of practical applications of plastic materials. Examples of such applications include electronic component packaging and solid state lighting. | |

| This work has been an international collaboration between Professor Alexander Balandin at UCR, Professor Konstantin Novoselov at University of Manchester, and engineers of Bluestone Global Tech, Wappingers Falls, New York. Hoda Malekpour, a researcher in Professor Balandin?s laboratory, and first author of the paper, performed thermal measurements of the samples prepared by the Bluestone Global Tech engineers. Professor Denis Nika, Moldova State University assisted with development of the theory of heat conduction in graphene laminate. | |

| The team used non-contact optothermal Raman method for the thermal studies. This is a direct steady-state measurement technique, which determines thermal conductivity directly without the need to calculate it from the thermal diffusivity data. In this technique, originally used for measuring the thermal properties of graphene, the micro-Raman spectrometer is used as a thermometer to determine the local temperature rise. The Raman excitation laser is also used as a heater. This technique well suited the flexible PET films coated with graphene laminate. | |

| "The present study utilized a relatively simple theoretical model to explain how thermal conductivity of graphene laminate depends on the parameters of laminate such as size of the flakes and concentration of impurities," says Balandin. "We will now develop a more detailed theoretical model, e.g. based on multi-scale simulation of heat transport, to assist in optimization of graphene laminate synthesis for thermal management applications." | |

| The work at UC Riverside on this project was supported by the National Science Foundation project ECCS 1307671 on Engineering the Thermal Properties of Graphene and UC Proof of Concept project on Graphene-Based Thermal Interface Materials and Heat Spreaders. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|