| Posted: Nov 24, 2014 | |

Foldable capacitive touch pad printed with silver nanowire ink |

|

| (Nanowerk Spotlight) Paper has become a popular substrate for fabricating electronics – it is a cheap, abundant material and easy to print on. Electronics printed on paper are inexpensive, flexible, and recyclable, and could lead to applications such as smart labels on foods and pharmaceuticals or as wearable medical sensors. Paper has been used for printed memory, as gas sensors ("Cheap nanotechnology paper-based gas sensors") or bioactive sensor to detect neurotoxins. | |

| Most printed electronics applications rely on some kind of ink formulated with conductive nanomaterials (read more: "Conductive nanomaterials for printed electronics applications"). Researchers have now introduced a rapid and facile method to fabricate a foldable capacitive touch pad using silver nanowire inks. | |

| The international research team has published their findings in the November 3, 2014 online edition of ACS Applied Materials & Interfaces ("Direct Writing on Paper of Foldable Capacitive Touch Pads with Silver Nanowire Inks"). | |

|

|

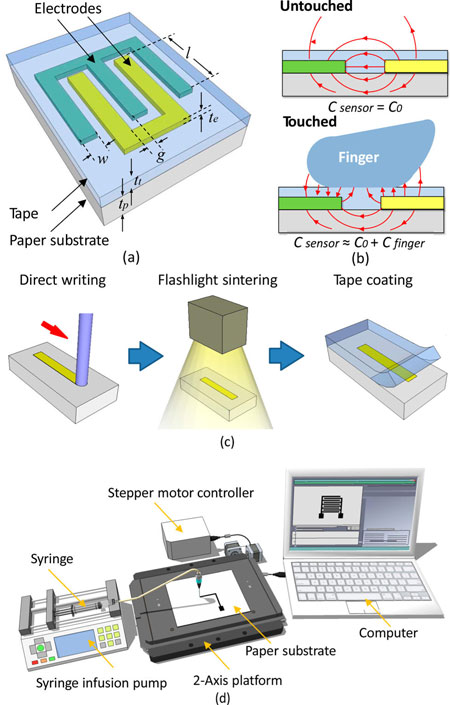

| Paper-based touch pad. (a) Schematic view of a paper-based touch pad. (b) Working principle of the paper-based touchpad. (c) Fabrication of the paper-based touchpad involving direct writing silver nanowire ink, flashlight sintering and tape coating. (d) The schematic of the direct writing equipment. (Reprinted with permission by American Chemical Society) | |

| "Paper electronics have been extensively studied in the past years but a printing protocol has yet to be developed," Anming Hu, an assistant professor at the University of Tennessee, Knoxville, tells Nanowerk. "Here, we wanted to develop a way to print it directly on a variety of paper to make a sensor that could respond to touch or specific molecules, such as glucose." | |

| "We also proposed a simplified theoretical model to elucidate the capacitive operating of touch pads, which closely approximated empirical data," notes Hu. | |

| Hu and his collaborators developed a technique that uses a 2D programmed printing machine with postdeposition sintering using a camera flash light to harden the deposited silver nanowire ink. | |

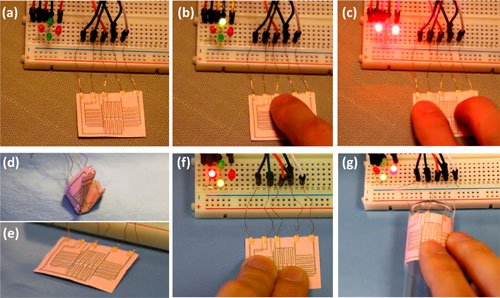

| The researchers point out that the resulting paper-based touchpads produced by direct writing with silver nanowire inks offer several distinct advantages over existing counterparts including: | |

|

|

|

|

|

| Four keypad touch pad in (a) untouched state, (b) touching with a single finger, (c) touching with two fingers. (d) Folded touch pad, (e) touch pad after 15 folding cycles, (f) unfolded touch pad with two fingers touching, (g) touch pad functioning on a curved surface. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| The team is now working on printable biosensors and energy devices with paper-based or polymer-based substrates. "We hope that we can integrate micro-sized batteries into a sensor and form a stand-alone microsystem," says Hu. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|