| Posted: Aug 04, 2015 | |

3D nanopatterning with memory-based, sequential wrinkling |

|

| (Nanowerk Spotlight) Wrinkling and buckling can occur at all length scales in materials composed of a stiff thin film on a strained supporting layer. When the strain is removed, either by thermal or mechanical stimuli, different surface patterns can form. | |

| This phenomenon – now starting to be realized at nanometer length scales – is emerging as a powerful bottom-up nanopatterning method to program surfaces with unique properties. It has many applications in the design and fabrication of flexible electronics and devices, micro-cell arrays, optical gratings, and so on. | |

| "Strain-induced surface wrinkling of a stiff skin on a soft base layer is emerging as a powerful method to realize ordered and disordered patterns over large areas," Teri W. Odom, Board of Lady Managers of the Columbian Exposition Professor of Chemistry and Professor of Materials Science and Engineering at Northwestern University, tells Nanowerk. "One of the next grand challenges is to create bio-mimetic, three-dimensional (3D) hierarchical architectures that display a diverse range of applications including reversible dry adhesion, selective filtration, and self-cleaning surfaces." | |

| She explains that two critical issues are important to design such functional surfaces: 1) control over length scale patterns; and 2) the ability to order features within hierarchy architectures. | |

| However, the realization of 3D hierarchy with independent control over wrinkle wavelength and orientation has not been yet achieved using existing wrinkling systems, which limits wrinkling as a bottom-up route to 3D functional surfaces. | |

| Now though, in new work, Odom and her team describe how a memory-based, sequential wrinkling process can transform flat polystyrene sheets into multi-scale, 3D hierarchical textures over large areas (>100 cm2). | |

| The researchers published their findings in the July 28, 2015 online edition of Nano Letters ("Controlled Three-Dimensional Hierarchical Structuring by Memory-Based, Sequential Wrinkling"). | |

|

|

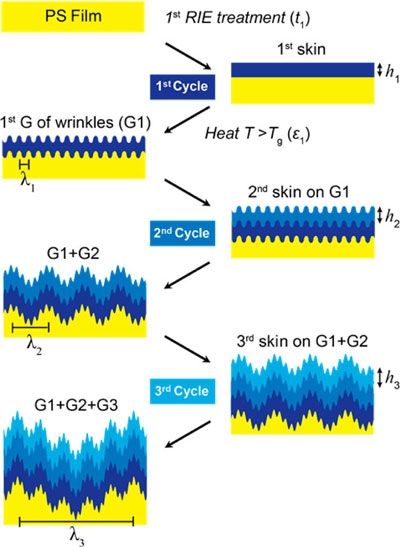

| Sequential wrinkling can generate multigenerational, hierarchical structures. CHF3 RIE plasma treatment produced a thin skin layer on PS substrates. The thickness h was controlled by changing treatment time (t); h is linear proportional to wrinkle wavelength (λ). Substrates were heated in an oven at T = 125°C. Sequential wrinkling could achieve multigenerational features (e.g., G1, G2, G3) with hierarchical structure. Orientation and periodicity of each G were controlled by changing t and strain (ε) direction (uniaxial or biaxial strain) for each cycle. (Reprinted with permission by American Chemical Society) | |

| In the fabrication process devised by the team, multiple cycles of plasma-mediated skin growth followed by directional strain relief of the substrate resulted in hierarchical architectures with characteristic generational (G) features. | |

| Independent control over wrinkle wavelength and wrinkle orientation for each G was achieved by tuning plasma treatment time and strain-relief direction for each cycle. | |

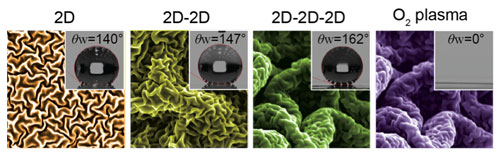

| The researchers demonstrated Lotus-type superhydrophobicity on three-dimensional G1-G2-G3 hierarchical wrinkles as well as tunable superhydrophilicity on these same substrates after oxygen plasma. | |

| "Our materials system provides a general approach for nanomanufacturing based on bottom-up sequential wrinkling that will benefit a diverse range of applications, and especially those that require large area (> cm2), multi-scale, three-dimensional patterns," notes Odom. | |

| A distinct feature of this process is that smaller features are preserved even as larger ones are formed; this the basis for memory-based processing to create hierarchical 3D architectures. | |

| "Memory-based sequential nanowrinkling can generate 3D hierarchical wrinkles with up to three different generations of wrinkles," explains Odom. "Multiple cycles of plasma- mediated skin growth followed by directional strain-relief enabled independent control over λ and orientation for each generation of wrinkles. Because of a very small Young's modulus ratio of the skin layer to polystyrene substrate (<10) as well as fine control over skin thickness, we achieved tunable λ at length scales, from tens of nanometers to tens of microns." | |

|

|

| By increasing the number of sequential wrinkling, normal 2D wrinkles are transformed to 3D hierarchical wrinkles where superhydrophobicity was achieved. Additional O2 plasma achieved continuous superhydrophobic-superhydrophilic transformation, accessing all possible wetting properties on a single surface. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| Access to such 3D, hierarchical wrinkles enabled superhydrophobicity as well as tunable superhydrophilicity using oxygen plasma to treat the same substrate. | |

| "Our memory-based hierarchical nanowrinkling provides a general approach to construct polymeric, 3D patterns that have potential in unidirectional liquid transport, anti-biofouling substrates, and omniphobic surfaces," concludes Odom. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|