| Posted: Aug 23, 2016 | |

Thermoelectric paper devices utilize waste heat to power electronics and sensors (w/video) |

|

| (Nanowerk Spotlight) The fact that temperature differentials (heat) are ubiquitously present in our environment makes thermoelectric energy harvesting a highly attractive research field. Flexible thermoelectric generators, especially as on-chip power sources, could have many applications in consumer and medical electronics – they may be used in implants; healthcare monitoring; wearable electronics; smart home systems; and remote wireless sensing systems. | |

| "To efficiently recover heat from the environment, thermoelectric generators should have maximum thermal contact with heat sources that often have arbitrary geometries, such as pipes or human bodies," Dong-Kyun Ko, an Assistant Professor of Electrical and Computer Engineering at New Jersey Institute of Technology, tells Nanowerk. "Therefore it is highly desirable to produce thermoelectric materials that are physically flexible. However, conventional thermoelectric materials are rigid and brittle and are not typically designed to be installed conformally on curved surfaces." | |

| New work from Ko's Nanoelectronics and Energy Conversion Lab highlights the fabrication of flexible thermoelectric materials and modules by merging colloidal nanomaterials (quantum dots) that can be tuned for efficient heat-to-electricity energy conversion with naturally abundant cellulose paper that are low in cost and have inherently low thermal conductivity (which is beneficial for thermoelectrics). | |

| The team has reported their findings in the August 9, 2017 online edition of Applied Materials & Interfaces ("Paper Thermoelectrics: Merging Nanotechnology with Naturally Abundant Fibrous Material"). | |

|

|

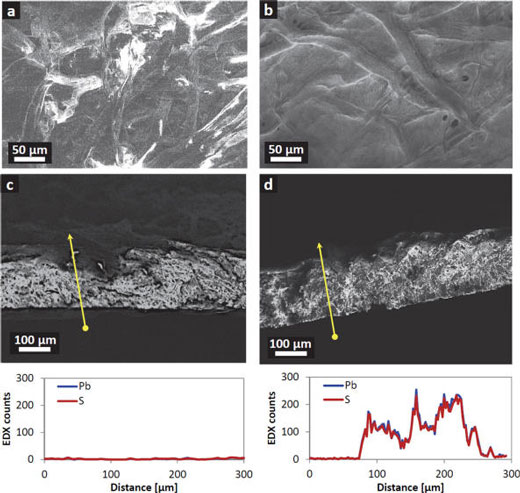

| SEM images of a filter paper before (a),(c), and after (b),(d) quantum dot (QD) dip-casting. (a),(b) Surface images and (c),(d) cross-sectional images with EDX line scan analysis. After QD dip-casting, smooth surface (b) and QD impregnated internal structure (d) are formed. (Reprinted with permission by American Chemical Society) | |

| The researchers demonstrate that paper thermoelectric materials can be fabricated using facile solution-processing and modules can be constructed by cutting p- and n-type paper strips into size and connecting them electrically in series and thermally in parallel without the use of any special equipment. | |

| This is in contrast to traditional bulk thermoelectrics that require time- and energy-intensive processing. | |

| To date, colloidal quantum dots have only been studied as a solution-processed material to deposit uniform thin-films on smooth substrate surfaces such as a silicon wafer or a glass substrate. | |

| "In our study, we adopt a new point of view and utilize colloidal quantum dots as 'impregnating solution'," explains Ko. "Upon dip-casting a blank paper into a colloidal quantum dot solution, quantum dots permeate throughout the entire thickness of the paper and transform it into a semiconducting nanocomposite." | |

| "In contrast to other paper-based electronics research, limitations arising from paper's porosity and surface roughness do not apply to our approach thus, making the fabrication potentially amenable for high-throughput, high-yield processing," he adds. | |

| Thermoelectric transport studies indicate that the energy conversion efficiency is limited by low electrical conductivity of the paper thermoelectric material. | |

| "Our research suggests that energy conversion efficiency can be significantly improved by enhancing the charge mobility," Ko points out. "We aim to enhance the rate of dot-to-dot charge transfer by modifying the surfaces of colloidal quantum dots." | |

| Paper thermoelectric modules, such as demonstrated by Ko's team, could potentially be used pervasively to power wireless sensor devices that will read and transmit important structural, security, or health related information perpetually (i.e. for the lifetime of the sensor) without the need for charging and replacing batteries. | |

| Unlike thin-films deposited on a substrate, paper thermoelectric strip samples are much easier to handle and manipulate, which allows facile property characterizations and rapid prototyping of power generation modules. | |

| Ko cautions that, in addition to enhancing the carrier mobility, controlled doping is required to optimize the thermoelectric property and ultimately to maximize the strips' efficiency; so don't expect these devices to be available at short notice. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|