Showing Spotlights 2281 - 2288 of 2777 in category All (newest first):

The list of great monuments and frescoes destroyed or seriously damaged by negligence or criminal action is dramatically increasing, and the biggest culprit is air pollution. Pollutants such as sulfur dioxide and nitrogen oxides are the most serious causes of degradation in carbonate stone, which in the form of marble, limestone and similar materials comprises some of the most important monuments and artifacts in the world. The main damage to monuments is that the stonework becomes sulphated through the transformation of calcium carbonate to calcium sulphate owing to the presence of sulphur dioxide. Two forms of deterioration then take place: the constitution of a black film in areas sheltered from the rain, and elsewhere the crumbling of the interior of the stone. For instance, UNESCO estimates that the surface eaten away annually in a cultural heritage site such as Venice represents 6 per cent of marble and stone monuments and 5 per cent of frescoes. The problem is not only what causes the damage but also how repairs are done. Quite often, the experts in charge of restoration work - architects, restorers, renovators - conduct their work without previous scientific studies of the damaged monument. Specifically the consolidation of decayed stone in historical buildings is a common intervention that can cause irreparable damage to the monument. Although commercial products, such as alkoxysilanes that are commonly used to consolidate stone, present unquestionable advantages they also present certain disadvantages totally ignored by the experts in charge of their application. Scientists in Spain are committed to the development of new nanotechnology materials specifically suited to stone-based historical structures. Their objective has been the development of a new nanomaterial which forms a crack-free gel in the pores of the treated stone.

The list of great monuments and frescoes destroyed or seriously damaged by negligence or criminal action is dramatically increasing, and the biggest culprit is air pollution. Pollutants such as sulfur dioxide and nitrogen oxides are the most serious causes of degradation in carbonate stone, which in the form of marble, limestone and similar materials comprises some of the most important monuments and artifacts in the world. The main damage to monuments is that the stonework becomes sulphated through the transformation of calcium carbonate to calcium sulphate owing to the presence of sulphur dioxide. Two forms of deterioration then take place: the constitution of a black film in areas sheltered from the rain, and elsewhere the crumbling of the interior of the stone. For instance, UNESCO estimates that the surface eaten away annually in a cultural heritage site such as Venice represents 6 per cent of marble and stone monuments and 5 per cent of frescoes. The problem is not only what causes the damage but also how repairs are done. Quite often, the experts in charge of restoration work - architects, restorers, renovators - conduct their work without previous scientific studies of the damaged monument. Specifically the consolidation of decayed stone in historical buildings is a common intervention that can cause irreparable damage to the monument. Although commercial products, such as alkoxysilanes that are commonly used to consolidate stone, present unquestionable advantages they also present certain disadvantages totally ignored by the experts in charge of their application. Scientists in Spain are committed to the development of new nanotechnology materials specifically suited to stone-based historical structures. Their objective has been the development of a new nanomaterial which forms a crack-free gel in the pores of the treated stone.

Feb 19th, 2008

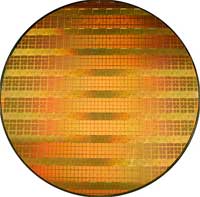

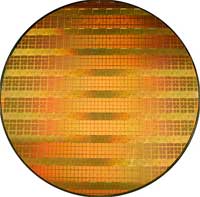

Due to their exceptional electronic and mechanical properties, as well as their nanoscale size, carbon nanotubes (CNTs) could become the active electronic elements in addressing next generation electronic requirements for which silicon is not a solution. Already, it has been shown extensively that semiconducting CNTs can be made into electronic components such as transistors and switches. Their thermal, mechanical, chemical stability, and large current-carrying capacity make CNTs attractive for applications not only in in electrical interconnects but also field-effect transistors, cold cathode field emitters, and sensors. Some of the problems in developing CNT-based electronic devices have to do with building reliable interconnections between CNTs and external electrical and mechanical systems and in developing a reliable fabrication batch process to allow for industrial-scale mass production that supports the direct manipulation and placement/growth of CNTs at specific locations. Pointing to a possible solution, researchers now have demonstrated controllable and simultaneous wafer-scale assembly of CNT networks by dielectrophoresis.

Due to their exceptional electronic and mechanical properties, as well as their nanoscale size, carbon nanotubes (CNTs) could become the active electronic elements in addressing next generation electronic requirements for which silicon is not a solution. Already, it has been shown extensively that semiconducting CNTs can be made into electronic components such as transistors and switches. Their thermal, mechanical, chemical stability, and large current-carrying capacity make CNTs attractive for applications not only in in electrical interconnects but also field-effect transistors, cold cathode field emitters, and sensors. Some of the problems in developing CNT-based electronic devices have to do with building reliable interconnections between CNTs and external electrical and mechanical systems and in developing a reliable fabrication batch process to allow for industrial-scale mass production that supports the direct manipulation and placement/growth of CNTs at specific locations. Pointing to a possible solution, researchers now have demonstrated controllable and simultaneous wafer-scale assembly of CNT networks by dielectrophoresis.

Feb 18th, 2008

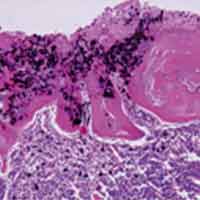

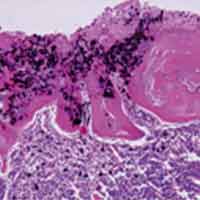

Carbon nanotubes (CNTs) have shown promise as an important new class of multifunctional building blocks and innovative tools in a large variety of nanotechnology applications, ranging from nanocomposite materials through nanoelectronics to biomedical applications. The exploration of CNTs in biomedical applications is well underway and exploratory uses have included CNT-coated implants, drug delivery and CNTs as components of biosensors. Notwithstanding the still not satisfactorily addressed issue of toxicity, CNTs' properties such as high strength, high electrical and thermal conductivities, and high specific surface area render them particularly useful in the fabrication of nanocomposite-derived biomedical devices. In one particular area - biomaterials applied to bone - CNTs are anticipated to improve the overall mechanical properties for applications such as high-strength arthroplasty prostheses expected to remain in the body for a long time, or fixation plates and screws that will not fail or impede healing of bone. In addition, CNTs are expected to be of use as local drug delivery systems or scaffolds to promote and guide bone tissue regeneration. A new study by Japanese scientists clearly demonstrates that multi-walled CNTs (MWCNTs) have good bone-tissue compatibility, permitting bone repair and becoming closely integrated with bone tissue. Furthermore, under certain circumstances, their results indicate that MWCNTs accelerate bone formation.

Carbon nanotubes (CNTs) have shown promise as an important new class of multifunctional building blocks and innovative tools in a large variety of nanotechnology applications, ranging from nanocomposite materials through nanoelectronics to biomedical applications. The exploration of CNTs in biomedical applications is well underway and exploratory uses have included CNT-coated implants, drug delivery and CNTs as components of biosensors. Notwithstanding the still not satisfactorily addressed issue of toxicity, CNTs' properties such as high strength, high electrical and thermal conductivities, and high specific surface area render them particularly useful in the fabrication of nanocomposite-derived biomedical devices. In one particular area - biomaterials applied to bone - CNTs are anticipated to improve the overall mechanical properties for applications such as high-strength arthroplasty prostheses expected to remain in the body for a long time, or fixation plates and screws that will not fail or impede healing of bone. In addition, CNTs are expected to be of use as local drug delivery systems or scaffolds to promote and guide bone tissue regeneration. A new study by Japanese scientists clearly demonstrates that multi-walled CNTs (MWCNTs) have good bone-tissue compatibility, permitting bone repair and becoming closely integrated with bone tissue. Furthermore, under certain circumstances, their results indicate that MWCNTs accelerate bone formation.

Feb 15th, 2008

Much has been written about the fascinating properties of spider silk, a biopolymer that is stronger than steel and more elastic than rubber. The silken threads possess a unique combination of mechanical properties: strength, extensibility and toughness. Of course this begs the obvious question: How is it possible that spider silk, produced by little creatures that evolved about 400 million years ago, can be as strong as steel - a modern alloy that plays a critical role in our infrastructure and which still attracts considerable R&D investments in its production technology? What is perplexing is that the atomic interactions (H-bonds) in spider silk are actually 100 to 1,000 times weaker than those in steel, or than those in the superfiber Kevlar, where covalent bonds are used. Hydrogen bonds are the basic chemical bonds that hold together proteins, similar to trusses and beams in buildings, and play a key role in controlling the behavior of these structures. In order to reach silk's mechanical properties, most synthetic materials must be much denser, thus much heavier and consume much more energy during their synthesis and transport. New analysis performed at MIT's Laboratory for Atomistic and Molecular Mechanics shows that the intriguing strength of spider silk may be made possible by precisely controlling the number and the geometry of H-bonds at a characteristic length scale. The physical concept is that by making many small elements work together cooperatively, the weaknesses of the individual components can be overcome. All this must happen at the nanoscale in order to be effective.

Much has been written about the fascinating properties of spider silk, a biopolymer that is stronger than steel and more elastic than rubber. The silken threads possess a unique combination of mechanical properties: strength, extensibility and toughness. Of course this begs the obvious question: How is it possible that spider silk, produced by little creatures that evolved about 400 million years ago, can be as strong as steel - a modern alloy that plays a critical role in our infrastructure and which still attracts considerable R&D investments in its production technology? What is perplexing is that the atomic interactions (H-bonds) in spider silk are actually 100 to 1,000 times weaker than those in steel, or than those in the superfiber Kevlar, where covalent bonds are used. Hydrogen bonds are the basic chemical bonds that hold together proteins, similar to trusses and beams in buildings, and play a key role in controlling the behavior of these structures. In order to reach silk's mechanical properties, most synthetic materials must be much denser, thus much heavier and consume much more energy during their synthesis and transport. New analysis performed at MIT's Laboratory for Atomistic and Molecular Mechanics shows that the intriguing strength of spider silk may be made possible by precisely controlling the number and the geometry of H-bonds at a characteristic length scale. The physical concept is that by making many small elements work together cooperatively, the weaknesses of the individual components can be overcome. All this must happen at the nanoscale in order to be effective.

Feb 14th, 2008

How much money would you pay to live forever? $100? $1,000? $100,000,000,000? Keeping in mind that forever is a long time; you could certainly arrange some kind of longterm loan, since you'd have plenty of time to make the payments. Historically, only religions have the lock on immortality. Thus guided by divine inspiration and a codicil transcribed directly from God, most religions profess the rebirth of consciousness after the body is disposed of. Well, guess what? There are some nanotechnologists who claim that in a few decades, death will be a choice rather than a requirement. Let's see how we can come to this rather heretical conclusion. Intel is already manufacturing devices with feature sizes about 20 nanometers across. A red blood cell is on the order of 10,000 nanometers across. In 2 dimensions we could stack about 250,000 components in the same space as a red blood cell. If the trends continue as far as 2017, which may be the end-point of Moore's Law we could be looking at a manufactured device the size of a red blood cell with 256,000,000 components. If we add the third dimension, that could translate into 65,536,000,000,000,000 components. Somewhere along the way, we're talking about the raw technical capability to produce a rather sophisticated robot small enough to wander around through your body doing whatever it has been programmed to do. The real question is, how practical is this speculation?

How much money would you pay to live forever? $100? $1,000? $100,000,000,000? Keeping in mind that forever is a long time; you could certainly arrange some kind of longterm loan, since you'd have plenty of time to make the payments. Historically, only religions have the lock on immortality. Thus guided by divine inspiration and a codicil transcribed directly from God, most religions profess the rebirth of consciousness after the body is disposed of. Well, guess what? There are some nanotechnologists who claim that in a few decades, death will be a choice rather than a requirement. Let's see how we can come to this rather heretical conclusion. Intel is already manufacturing devices with feature sizes about 20 nanometers across. A red blood cell is on the order of 10,000 nanometers across. In 2 dimensions we could stack about 250,000 components in the same space as a red blood cell. If the trends continue as far as 2017, which may be the end-point of Moore's Law we could be looking at a manufactured device the size of a red blood cell with 256,000,000 components. If we add the third dimension, that could translate into 65,536,000,000,000,000 components. Somewhere along the way, we're talking about the raw technical capability to produce a rather sophisticated robot small enough to wander around through your body doing whatever it has been programmed to do. The real question is, how practical is this speculation?

Feb 13th, 2008

Over the last decade, the European Union (EU) has established a strong knowledge base in nanosciences and developed significant research and development capabilities in nanotechnology. In accordance with the Treaty of the EU, applications of nanotechnology need to comply with the requirements for a high level of public health, safety, consumer and environmental protection (Treaty articles require that a 'high level of human health protection [...] be ensured in the definition and implementation of all Community policies and activities' and that 'consumer protection requirements [...] be taken into account in defining and implementing other Community policies and activities'). Through its Framework Programs (FP), Europe's strategy has been and is to support the safe, responsible development of nanotechnology while providing favourable conditions for industrial innovation. Following this commitment of addressing upfront the potential risks, the European Commission has boosted support for specific collaborative research into the potential impact of nanoparticles on human health and the environment since the Framework Programme 5 (FP5) which started in 1999. These activities have been continued and reinforced in FP6 and in FP7 where several topics were launched specifically addressing the safety of nanomaterials. At the same time, the EU Members States have also been funding research in that field, but a consolidated overview of these ongoing or finished projects was not yet available so the magnitude of these national efforts was difficult to evaluate. The EU now has released a report that lists all nanotechnology research funding in the Community that address in particular the health and environmental impact of nanoparticles.

Over the last decade, the European Union (EU) has established a strong knowledge base in nanosciences and developed significant research and development capabilities in nanotechnology. In accordance with the Treaty of the EU, applications of nanotechnology need to comply with the requirements for a high level of public health, safety, consumer and environmental protection (Treaty articles require that a 'high level of human health protection [...] be ensured in the definition and implementation of all Community policies and activities' and that 'consumer protection requirements [...] be taken into account in defining and implementing other Community policies and activities'). Through its Framework Programs (FP), Europe's strategy has been and is to support the safe, responsible development of nanotechnology while providing favourable conditions for industrial innovation. Following this commitment of addressing upfront the potential risks, the European Commission has boosted support for specific collaborative research into the potential impact of nanoparticles on human health and the environment since the Framework Programme 5 (FP5) which started in 1999. These activities have been continued and reinforced in FP6 and in FP7 where several topics were launched specifically addressing the safety of nanomaterials. At the same time, the EU Members States have also been funding research in that field, but a consolidated overview of these ongoing or finished projects was not yet available so the magnitude of these national efforts was difficult to evaluate. The EU now has released a report that lists all nanotechnology research funding in the Community that address in particular the health and environmental impact of nanoparticles.

Feb 12th, 2008

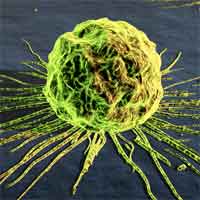

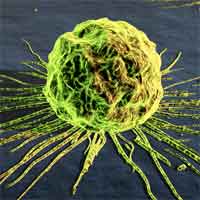

Photodynamic therapy (PDT) is a cancer treatment that combines a chemical compound, called a photosensitizer, with a particular type of light to kill cancer cells. The treatment works like this: the photosensitizing agent is injected into the bloodstream. The agent is absorbed by cells all over the body, but stays in cancer cells longer than it does in normal cells. One to three days after injection, when most of the agent has left normal cells but remains in cancer cells, the tumor is exposed to light. The photosensitizer in the tumor absorbs the light and produces an active form of oxygen (singlet oxygen) that destroys nearby cancer cells. PDT has been used for the past 30 years and is a treatment that works. PDT takes very little time, is often done as an outpatient, can be accurately targeted to the affected area, can be repeated, and has no long-term side effects. It also isn't as expensive or invasive as some other cancer treatment options. The limitation of this form of cancer treatment is that the light needed to activate most photosensitizers cannot pass through more than one centimeter of tissue. For this reason, PDT is usually used to treat tumors on or just under the skin or on the lining of internal organs or cavities. PDT is also less effective in treating large or deep tumors, because the light cannot pass far into these tumors. Researchers have now proposed a new PDT system in which the light is generated by x-ray scintillation nanoparticles with attached photosensitizers. When the nanoparticle-photosensitizer conjugates are targeted to tumors and stimulated by x-rays during radiotherapy, the particles generate visible light that can activate the photosensitizers for photodynamic therapy. Therefore, the radiation and photodynamic therapies are combined and occur simultaneously, and the tumor destruction can be more efficient. More importantly, it can be used for deep tumor treatment as x-rays can penetrate through tissue.

Photodynamic therapy (PDT) is a cancer treatment that combines a chemical compound, called a photosensitizer, with a particular type of light to kill cancer cells. The treatment works like this: the photosensitizing agent is injected into the bloodstream. The agent is absorbed by cells all over the body, but stays in cancer cells longer than it does in normal cells. One to three days after injection, when most of the agent has left normal cells but remains in cancer cells, the tumor is exposed to light. The photosensitizer in the tumor absorbs the light and produces an active form of oxygen (singlet oxygen) that destroys nearby cancer cells. PDT has been used for the past 30 years and is a treatment that works. PDT takes very little time, is often done as an outpatient, can be accurately targeted to the affected area, can be repeated, and has no long-term side effects. It also isn't as expensive or invasive as some other cancer treatment options. The limitation of this form of cancer treatment is that the light needed to activate most photosensitizers cannot pass through more than one centimeter of tissue. For this reason, PDT is usually used to treat tumors on or just under the skin or on the lining of internal organs or cavities. PDT is also less effective in treating large or deep tumors, because the light cannot pass far into these tumors. Researchers have now proposed a new PDT system in which the light is generated by x-ray scintillation nanoparticles with attached photosensitizers. When the nanoparticle-photosensitizer conjugates are targeted to tumors and stimulated by x-rays during radiotherapy, the particles generate visible light that can activate the photosensitizers for photodynamic therapy. Therefore, the radiation and photodynamic therapies are combined and occur simultaneously, and the tumor destruction can be more efficient. More importantly, it can be used for deep tumor treatment as x-rays can penetrate through tissue.

Feb 11th, 2008

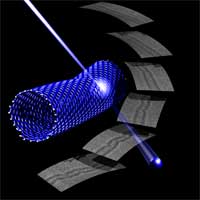

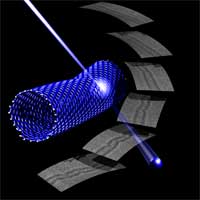

Electron microscopy is a delicate balancing act between using the highest energy electrons possible in order to obtain the best image while avoiding destruction of the sample under investigation. Trouble is, the electron beam does not just observe, it also interacts with the structure that is observed. This can be critical for fragile samples such as nanostructures: the transfer of energy from the electron beam can be sufficient that atoms are knocked right out of the material. In the worst case the sample is destroyed in front of your eyes. Scientists in Orsay, France have turned this problem to their advantage. They have developed a new approach to shaping nanomaterials atom by atom, using a scanning transmission electron microscope (STEM) as a nanometrically precise cutting tool. In this way they 'carve' their materials, such as carbon nanotubes, by removing individual atoms from specifically chosen locations. This technique has the added advantage that scientists can observe what they are doing at the same time. The new technique demonstrates a 'nanoelectron- lithography' of single walled nanotubes, a top down approach to locally control their nanostructures.

Electron microscopy is a delicate balancing act between using the highest energy electrons possible in order to obtain the best image while avoiding destruction of the sample under investigation. Trouble is, the electron beam does not just observe, it also interacts with the structure that is observed. This can be critical for fragile samples such as nanostructures: the transfer of energy from the electron beam can be sufficient that atoms are knocked right out of the material. In the worst case the sample is destroyed in front of your eyes. Scientists in Orsay, France have turned this problem to their advantage. They have developed a new approach to shaping nanomaterials atom by atom, using a scanning transmission electron microscope (STEM) as a nanometrically precise cutting tool. In this way they 'carve' their materials, such as carbon nanotubes, by removing individual atoms from specifically chosen locations. This technique has the added advantage that scientists can observe what they are doing at the same time. The new technique demonstrates a 'nanoelectron- lithography' of single walled nanotubes, a top down approach to locally control their nanostructures.

Feb 8th, 2008

The list of great monuments and frescoes destroyed or seriously damaged by negligence or criminal action is dramatically increasing, and the biggest culprit is air pollution. Pollutants such as sulfur dioxide and nitrogen oxides are the most serious causes of degradation in carbonate stone, which in the form of marble, limestone and similar materials comprises some of the most important monuments and artifacts in the world. The main damage to monuments is that the stonework becomes sulphated through the transformation of calcium carbonate to calcium sulphate owing to the presence of sulphur dioxide. Two forms of deterioration then take place: the constitution of a black film in areas sheltered from the rain, and elsewhere the crumbling of the interior of the stone. For instance, UNESCO estimates that the surface eaten away annually in a cultural heritage site such as Venice represents 6 per cent of marble and stone monuments and 5 per cent of frescoes. The problem is not only what causes the damage but also how repairs are done. Quite often, the experts in charge of restoration work - architects, restorers, renovators - conduct their work without previous scientific studies of the damaged monument. Specifically the consolidation of decayed stone in historical buildings is a common intervention that can cause irreparable damage to the monument. Although commercial products, such as alkoxysilanes that are commonly used to consolidate stone, present unquestionable advantages they also present certain disadvantages totally ignored by the experts in charge of their application. Scientists in Spain are committed to the development of new nanotechnology materials specifically suited to stone-based historical structures. Their objective has been the development of a new nanomaterial which forms a crack-free gel in the pores of the treated stone.

The list of great monuments and frescoes destroyed or seriously damaged by negligence or criminal action is dramatically increasing, and the biggest culprit is air pollution. Pollutants such as sulfur dioxide and nitrogen oxides are the most serious causes of degradation in carbonate stone, which in the form of marble, limestone and similar materials comprises some of the most important monuments and artifacts in the world. The main damage to monuments is that the stonework becomes sulphated through the transformation of calcium carbonate to calcium sulphate owing to the presence of sulphur dioxide. Two forms of deterioration then take place: the constitution of a black film in areas sheltered from the rain, and elsewhere the crumbling of the interior of the stone. For instance, UNESCO estimates that the surface eaten away annually in a cultural heritage site such as Venice represents 6 per cent of marble and stone monuments and 5 per cent of frescoes. The problem is not only what causes the damage but also how repairs are done. Quite often, the experts in charge of restoration work - architects, restorers, renovators - conduct their work without previous scientific studies of the damaged monument. Specifically the consolidation of decayed stone in historical buildings is a common intervention that can cause irreparable damage to the monument. Although commercial products, such as alkoxysilanes that are commonly used to consolidate stone, present unquestionable advantages they also present certain disadvantages totally ignored by the experts in charge of their application. Scientists in Spain are committed to the development of new nanotechnology materials specifically suited to stone-based historical structures. Their objective has been the development of a new nanomaterial which forms a crack-free gel in the pores of the treated stone.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed