| Posted: Jan 22, 2018 | |

Sculpting liquids |

|

| (Nanowerk Spotlight) Countless commercial and industrial products are routinely produced by manufacturing processes where solid parts, for instance thermoplastics, are molded through injecting molten polymer into a cast and removing the finished shape once cooled. | |

| This process is well understood for solid materials. If the characteristics and properties of a liquid are of interest, e.g., ion transport or mobility, the ability to structure liquids into complex shapes becomes highly desirable. It would open a wide range of potential applications in areas such as all-liquid reaction vessels, energy storage materials, all-liquid electronic devices, and microfluidic devices. | |

| Researchers now have developed a very simple route to structure liquids by all-liquid molding. As an international team from Beijing University of Chemical Technology and Lawrence Berkeley National Laboratory reports in Advanced Materials ("Liquid Letters"), liquids can be shaped using a molding strategy that achieves high-fidelity shape transfer and preservation of the shape. | |

| "It has been well-known that by interfacial jamming of nanoparticle surfactants, liquids can be shaped by an electric field first, and maintained in a nonequilibirum state," Shaowei Shi, the paper's first author, explains to Nanowerk. "So we started thinking about whether we could use a process used for molding solid parts to mold liquids." | |

| In previous work, the scientists already reported the use of cellulose nanocrystals that interact with amine-terminated polystyrene at the water–toluene interface to form nanoparticle surfactants (Angewandte Chemie, "Liquid Tubule Formation and Stabilization Using Cellulose Nanocrystal Surfactants"). | |

| In their new paper, the team now demonstrates a very simple, robust, and versatile strategy using cellulose nanocrystal surfactants (CNCSs) to mold all-liquid objects that are responsive and adaptive and that can be released from a mold to generate an all-liquid object that retains the shape and details of the mold with high fidelity. | |

|

|

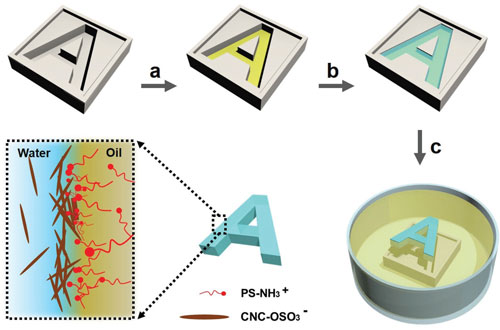

| Cartoon shows all-liquid molding process. a) Filling ∼100 µL CCl4 containing PS-NH2. b) Filling ∼200 µL CNC aqueous solution. c) Immersing the mold into 10 mL CCl4 containing PS-NH2. [PS-NH2] = 10 mg mL-1, [CNC] = 10 mg mL-1, and Mw (PS-NH2) = 1000 g mol-1. (Reprinted with permission by Wiley-VCH Verlag) | |

| Shi describes the fabrication process: "We placed an aqueous cellulose nanocrystal dispersion into the mold that has been prewetted with an oil solution of amine-terminated polymer ligands. Cellulose nanocrystal surfactants form at the oil–water interface, while the surface of the liquid at the top of the mold is open to air. We then immersed the filled mold in an oil solution of the amine-terminated polymer ligands. Very rapidly, CNCSs form on the exposed surface." | |

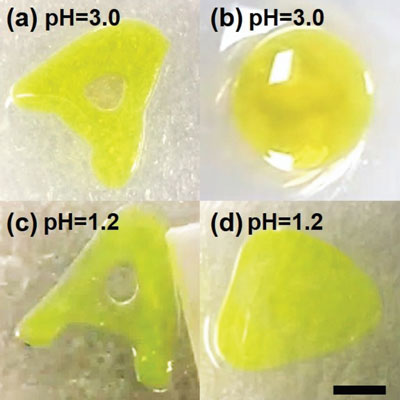

| "The density of the oil is higher than that of the aqueous phase, which causes the aqueous phase, now fully encapsulated with CNCSs, to rise out of the mold," he continues. "As the liquid object rises, the interfacial area begins to decrease and the CNCSs at the water–oil interface jam, arresting any shape change, and lock-in the shape indefinitely. The shape of the liquid object can be changed subsequently, by applying an external force, like an electric field, shear, or change in the pH." | |

|

|

| Dyed liquid letter “A” molded in different water–oil systems. a) Water with CNCs, and CCl4 with PS-NH2. b) Water with CNCs and pure CCl4. c) Water with CNCs, and CCl4 with PS-NH2. d) Water with CNCs and pure CCl4. [CNC] = 10 mg mL-1, [PS-NH2] = 10 mg mL-1, [Na-Fluorescein] = 0.1 mg mL-1, and scale bar = 5 mm. (Reprinted with permission by Wiley-VCH Verlag) | |

| Shi notes that release from the mold is trivial, taking advantage of the density difference between the liquid being molded and the surrounding liquid, where the shaped liquid rises or levitates from the mold. | |

| Liquids can be manipulated according to the shape of the mold. Such sculpted liquids retain all the characteristics of the liquids but retain shape indefinitely, very much like a solid, and provide a new platform for next-generation soft materials. | |

| Going forward, the team plans to study how smaller sizes of the structured liquids can be obtained using the all-liquid molding. They also will try to realize structured liquids in all aqueous systems. | |

| "Future research directions for the structured liquids could be all-liquid 3D-printing and bicontinuous interfacially jammed emulsion gels ('bijels')," Shi concludes. "The challenges will lie in dealing with mechanical properties and interfacial dynamics." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|