| Posted: Mar 25, 2008 | |

Nanotechnology composite materials for next generation biomedical applications |

|

| (Nanowerk Spotlight) Polymethylmethacrylate (PMMA), a clear plastic, is a pretty versatile material. Plexiglas windows are made from PMMA. Acrylic paints contain PMMA. It also remains one of the most enduring materials in orthopedic surgery where it has a central role in the success of total joint replacement. Being part of a group of medical materials called 'bone cement', its use includes the fixation of biomaterials such as artificial joints to bone, the filling of bone defects and, also, as a drug-delivery system. Beginning in the 1970s, many successful results have been reported for total hip replacement using PMMA cement; however, failures of fixation have also occurred. The fixation strength of PMMA cement to bone is mainly dependent on mechanical interlocking, but it is known that a fibrous tissue layer intervenes between cement and bone - PMMA cement never bonds directly to the bone. | |

| One of the problems associated with the conventional types of bone cement used is their unsatisfactory mechanical and exothermic reaction properties. Other problems with PMMA cement include the biological response, leakage of the monomer of methylmethacrylate and a high curing temperature, which can damage cell activity. Ideally, a bone cement material must functionally match the mechanical behavior of the tissue to be replaced, it must be able to form a stable interface with the surrounding natural tissue and be effective in guided tissue regenerative procedures, it should be easy to handle, biologically compatible, non-supporting of microbial growth, and non-allergenic. | |

| Hydroxyapatite (HA) is another key constituent of bone cements because of its ability to bond chemically with living bone tissues; this is due to its similar chemical composition and crystal structure to apatite in the human skeletal system. However, the intrinsic brittleness and poor strength of sintered HA restricts its clinical applications under load-bearing conditions. | |

| A novel nanocomposite of carbon-nanotube-reinforced PMMA/HA is a demonstration of how nanomaterials will play an increasing role in the synthesis of next-generation biomedical applications. | |

| "The combination of PMMA and hydroxyapatite with multi-walled carbon nanotubes (MWCNTs) seems to be a path of great promise to be explored – carbon nanotubes, due to their small dimensions and high aspect ratio, exhibit exceptional physical and chemical properties. No other material can compete with their outstanding combination of mechanical, thermal and electronic properties" Dr. Manoj Kumar Singh tells Nanowerk. "MWCNTs are an outstanding reinforcement material for composites. Therefore, our introduction of an appropriate percentage of MWCNTs as a reinforcement material in the PMMA/HA matrix led to a novel, high-strength nanocomposite." | |

| Singh, a principal investigator in the TEMA-NRD in the Department of Mechanical Engineering at the University of Aveiro in Portugal, is first author of a paper in the March 11, 2008 online edition of Advanced Functional Materials that describes a a freeze-granulation technique to prepare this novel nanocomposite material ("Hydroxyapatite Modified with Carbon-Nanotube-Reinforced Poly(methyl methacrylate): A Nanocomposite Material for Biomedical Applications"). Singh was part of an international research team that included scientists from the University of Aveiro, Georgia Institute of Technology in Atlanta, Georgia, and the University Louis Pasteur in Strasbourg, France. | |

|

|

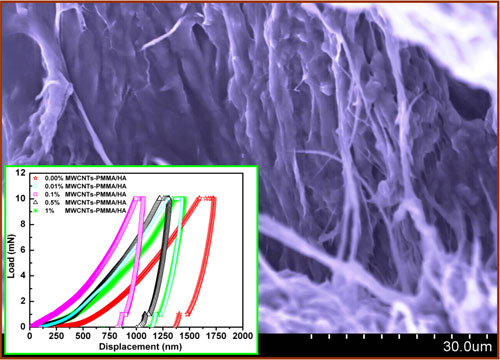

| FE-SEM image of a 0.1% MWCNT-reinforced PMMA/HA sample prepared by the freeze- granulation technique. Inset shows typical load–displacement curves of Nanoindentations made at a peak indentation load of 10 mN on PMMA/HA nanocomposites with various amounts of MWCNT reinforcement. (Image: Dr. Singh, University of Aveiro) | |

| The research team found that the use of freeze-granulation, an already mature and well-understood technique based on instant freezing of sprayed drops and subsequent freeze-drying, increases material homogeneity and also enhances the dispersion of the MWCNTs in the composite matrix. | |

| Mechanical tests indicated that 0.1% concentration in weight of MWCNTs in the PMMA modified HA nanocomposite material yields the best mechanical properties. Beyond this limit, further addition of MWCNTs to the PMMA/HA matrix yields a considerable decrease of these mechanical properties. | |

| "The dispersion of the MWCNTs is likely the most pressing issue when preparing this nanocomposite, as the MWCNTs should be uniformly dispersed to guarantee that they are individually coated with PMMA-modified HA composite, which is required to guarantee an efficient load transfer to the MWCNTs network" says Singh. "This also results in a more uniform stress distribution and minimizes the presence of loci of high stress concentration. We found that it is necessary to control the percentage of MWCNTs in the nanocomposite material – a large amount of MWCNTs leads them to bundle up in weakly interacting tubes as a result of the van der Waals attraction and it will decrease the interfacial interaction between the base material and the MWCNTs; while a small amount of MWCNTs below a certain threshold makes the composite material ineffective." | |

| The research team performed fatigue tests in artificial bones to confirm the superior performance characteristics of their nanocomposite material. "In the tests, after one million cycles, the nanocomposite of composition 0.1% MWCNT– PMMA/HA does not present any signal of crack propagation and delamination" says Singh. "But when we performed the same type of fatigue tests for PMMA-only nanocomposites, we can clearly observe delamination and cracks." | |

| This novel nanocomposite material could be specifically used in bone cement that requires high strength and bone repair. Singh and his collaborators are also very interested in developing orthopedic tools, such as bone fixation screws, which can be fully absorbed by the living organism after their mission is accomplished. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.