| Apr 09, 2020 | |

Improving the toughness of graphene films |

|

| (Nanowerk Spotlight) Graphene films with high toughness, strength and electrical conductivity have many promising applications as lightweight structural materials for a variety of uses, from aircraft and automobile bodies to windmill blades and sports equipment; as flexible conductive materials for increasingly popular wearable electronics; and as electromagnetic (EM) interference shielding materials for eliminating the EM pollution of diverse electronic devices. | |

| In a previous Nanowerk Spotlight ('Stitching' together ultrastrong graphene films) we reported on a strategy to 'stitch' reduced graphene oxide (rGO) nanosheets into ultra-strong and highly conductive graphene films using only small amounts of cross-linker. | |

| Advancing their previous work, the research team, led by professor Qunfeng Cheng at Beihang University in Beijing, has now developed black phosphorus (BP) functionalized graphene films, resulting in record toughness. | |

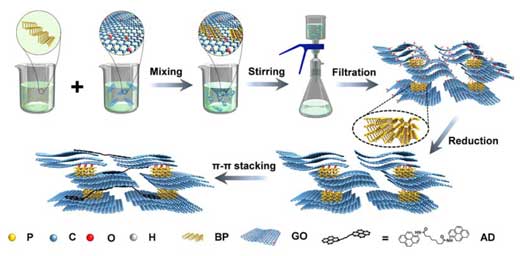

| "The formation of covalent bonding P-O-C between BP and graphene oxide (GO) nanosheets not only reduces the voids of GO film but also improves the alignment degree of GO nanosheets, resulting in high compactness of the GO film," Cheng tells Nanowerk. "After further chemical reduction and π-π stacking interactions by conjugated AD molecules, the alignment degree of reduced graphene oxide (rGO) nanosheets was further improved, and the voids in lamellar graphene film were also further reduced. The toughness of this graphene film reaches as high as ∼51.8 MJ m-3 – the highest value recorded to date." | |

| The research team points out that the resulting ultratough black phosphorus functionalized graphene films with high tensile strength and excellent conductivity also exhibit high ambient stability and electromagnetic shielding performance. | |

| "Our novel strategy can provide an inspiration for converting low-priced graphite powders into high performance graphene-based films for diverse commercial uses in the future," Cheng notes. "These films could find many applications such as structural materials for various commercial applications in aerospace or for other functional materials in electromagnetic interference shielding, flexible energy storage, and portable electronics." | |

| The team reports their findings in ACS Applied Materials & Interfaces ("Robust Bioinspired Graphene Film via π-π Cross-linking"). | |

|

|

| Illustration of the manufacturing process of the rGO-BP-AD film by stirring, vacuum filtration, chemical reduction, and chemical cross-linking with the long-chain AD molecules via π-π stacking interaction. (Reprinted with permission by National Academy of Sciences) (click on image to enlarge) | |

| Researchers have been aware of the fact that graphene films always contain voids, which dramatically decrease load transfer efficiency and results in low mechanical properties. | |

| To address this problem, the team's strategy – functionalization of the GO nanosheets by BP nanosheets through P-O-C covalent bonding – succeeded in reducing the voids in lamellar graphene film and makes the graphene film much more compact, while at the same time improving the alignment degree of GO nanosheets. | |

| "Our strategy opens an avenue for the assembly of graphene nanosheets into ultratough, strong, and conductive graphene-based film," says Cheng. "In addition, our strengthening and toughening mechanisms can also provide an avenue for the assembly of graphene nanosheets and other small nanosheets into high-toughness graphene-based films using covalent bonding to reduce voids and enhance alignment degree." | |

| The team's work is built on two previous papers. One found that black phosphorus is easily oxidized in air, but the stability of BP can be improved through coating with polymers (Journal of Materials Chemistry A, "A new strategy for air-stable black phosphorus reinforced PVA nanocomposites"). The other demonstrated that long chain conjugated molecules easily form π-π stacking with graphene, resulting in high toughness graphene films (ACS Applied Materials & Interfaces, "Robust Bioinspired Graphene Film via π-π Cross-linking"). | |

| "In fact, we had no idea what will happen before mixing the black phosphorus and graphene oxide nanosheets," recounts Cheng. "I asked my two PhD students, Tianzhu Zhou and Hong Ni, to try some experiments. For example, what will happen when mixing GO and BP nanosheets together by continuous stirring overnight?" | |

| One of these experiments resulted in the hybrid GO-BP nanosheets that are the basis for this work. Atomic force microscopy (AFM) showed that there were many single layers of BP nanoplatelets on the surface of the GO nanosheet. The BP and GO monolayer nanosheets in mixing solution reacted completely under ambient temperature, which was verified via the zeta potential. The researchers assembled the GO-BP film by vacuum-assisted filtration and then chemically reduced it by hydroiodic acid into rGO-BP film. | |

| Measurement of the mechanical properties of these novel films confirm the researchers' assumptions: The toughness of rGO-BP film (15.6 MJ m-3) is 6 times higher than that of rGO film (2.5 MJ m-3), and the toughness of rGO-BP-AD film (51.8 MJ m-3) shows a 21 times improvement over rGO film after adding π-π stacking of AD molecules. | |

| "The performance of the graphene/black phosphorus films that we demonstrated still is lower than that of single-layer graphene nanosheets, so we need to develop new strategies to further enhance the toughness, tensile strength, and electrical conductivity of macroscale graphene films for many practical applications," Cheng concludes. "In addition, although our graphene films show high toughness under room temperature, many practical applications will take place in extreme environments, such as outer space with intense radiation, and frequent variations of high and low temperatures." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|