| Posted: Mar 25, 2010 | |

Nanoscale investigation advances bioethanol production from woods |

|

| (Nanowerk Spotlight) One approach to converting our energy production system to renewable sources is the introduction of biomass schemes (bioethanol, -diesel or -gas). Bioethanol, unlike petroleum, is a form of renewable energy that can be produced from common agricultural feedstocks such as sugar cane or corn. Ethanol is already widely used in siome countries, mainly as biofuel additive for gasoline. The tremendous hype about bioethanol in the past few years has now been followed by a debate about how useful bioethanol actually can replace gasoline. Concerns about its production and use relate to the large amount of arable land required for crops, as well as the energy and pollution balance of the whole cycle of ethanol production. | |

| Recent developments with cellulosic ethanol production and commercialization may allay some of these concerns. Cellulosic ethanol offers promise because here cellulose fibers, a major and universal component in plant cells walls, can be used to produce ethanol. That means any plant material, from grass to wood, and not just edible crops, could be used in the production of ethanol fuels. Consequently, cellulosic ethanol could allow ethanol fuels to play a much bigger role in the future than previously thought. | |

| With regard to cellulosic production and commercialization, bioethanol production from woody biomass by enzymatic hydrolysis of cellulosic components and fermentation has attracted much attention. | |

| "In this process, pretreatment is important to improve enzymatic degradability of cellulose," explains Takashi Endo. "A milling process is one of the most effective methods for pretreatment, but its high cost has been a problem. Recently we have developed an economically feasible wet-mechanochemical process as milling pretreatment, which can unravel cellulosic components into nanoscale fibers. The nanofibrous product that we obtained this way showed a high enzymatic accessibility, while keeping the cellulose crystalline structure and the lignin content. This process is based on the understanding of the nanoscopic structural characteristics of wood and cellulose." | |

| Endo leads the research team of the Biomass Technology Research Center at AIST in Japan. In a recent paper in Synthesiology ("Bioethanol Production from woods with the aid of nanotechnology") he summarizes his research results for cellulose milling. He emphasizes that this process is based on the understanding of the nanoscopic structural characteristics of wood and cellulose. | |

| "Wood structure is nanostructure" says Endo. "A wood fiber is composed of nanosize cellulose microfibrils held together using hemicellulose and lignin as adhesives, and the 'wood structure' is formed by laying the vessels and tracheids that carry water in the middle and then layering the microfibrils around them. The toughness of wood results from this layer structure. This is often likened to a barrel or tub. A tub is strong because the boards are arranged circularly in a vertical direction, and the hoop is used to bundle them together in a direction 90 degrees of the boards. In the wood structure, the nanosize cellulose microfibrils act like the boards and hoops of a tub, and form a highly layered nanostructure. This tough wood structure makes the pretreatment for enzymatic saccharification very difficult." | |

|

|

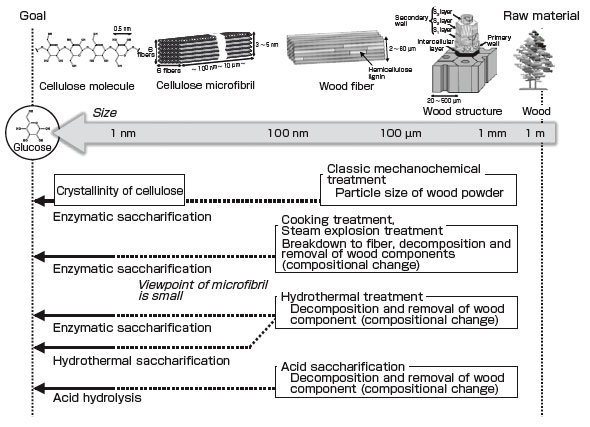

| Size image of (conventional) pretreatment technology for enzymatic saccharification. (Source: Synthesiology - English edition Vol.2 No.4 (2010) | |

| The basic steps for large scale production of ethanol are: microbial (yeast) fermentation of sugars, distillation, dehydration, and denaturing. Prior to fermentation, some crops require saccharification – the use of enzymes to convert the starch from the the plant cellulose into sugar. | |

| The problem with wood is that it doesn't react with enzymes. It therefore is necessary to develop a suitable pre-treatment technology that allows enzymatic saccharification. In his paper, Endo briefly discusses the various pre-treatments that have been used – milling, cooking, and steam explosion – and mentions that they all have disadvantageous issues like high power consumption, waste liquids, or dependency on certain types of wood. In their work, Endo's team revisits the milling treatment but also attempts the development of the optimal pretreatment technology by combining several technologies. | |

| "The enzymatic saccharification reaction of cellulose is a solid-liquid reaction of solid cellulose and enzyme dissolved in water," explains Endo. "In general, to promote the solid-liquid reaction efficiently, the solid can be broken down finely to increase the contact surface with the liquid. The microfibril in the wood is the minimum unit of solid cellulose. Saccharification is expected to progress smoothly if the cellulose can be dissolved and separated into one unit of molecule, but the enzyme will easily become deactivated in a solvent that can dissolve cellulose." | |

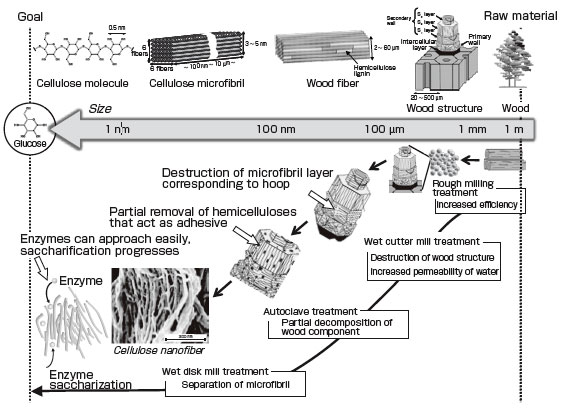

| In their work, Endo and his team developed a method for actually unraveling the wood's microfibril and thereby enabling enzymatic saccharification. They used a wet mechanochemical treatment with ball milling. | |

| "The wood structure is an assembly of microfibrils, and the assembly force is a weak bond such as a hydrogen bond" says Endo. "What we found is that by using a water molecule like a wedge in the wet mechanochemical treatment to break the hydrogen bonds between the microfibrils, we achieved a separation of microfibril effective enough for enzymatic saccharification" | |

| Endo pints out that the advantage of the mechanochemical treatment is that the costs in other processes of the bioethanol production can be reduced greatly. | |

| "In the mechanochemical treatment, enzymatic saccharification and fermentation progress efficiently without the chemical treatments such as lignin removal" he says. "Also, dependency on raw material is low, and the process can be applied as the pretreatment of hardwoods, softwoods, straws, and others. The greatest advantage is the reduction in the cost of enzymes such as cellulase, which in some cases dominate over half the cost of bioethanol production. The mechanochemically treated products can be sufficiently saccharified with relatively small a mount of enzymes." | |

|

|

| Size image of combination wet mechanochemical treatment. (Source: Synthesiology - English edition Vol.2 No.4 (2010) | |

| At AIST Endo's group has already built an integrated manufacturing miniplant capable of treating 200 kg of diverse biomass at once that incorporates their pretreatment process and the saccharification and fermentation processes. | |

| To summarize their approach, Endo notes that only as a result of studying the conventional technology were they able to find that the viewpoints from the wood chemistry and cellulose chemistry of the target wood were necessary for the development of a practical pretreatment technology. "Moreover, by combining the knowledge and technologies of other fields such as macromolecular chemistry and papermaking, we were able to construct a pretreatment technology based on a new concept." | |

| He cautions that there are many unclear points about the properties and reaction mechanism of the enzymes for the cellulose nanofiber obtained by pretreatment, and state-of-the-art analyses are necessary. "In the future, the technologies and knowledge of biotechnology, chemical engineering, thermal engineering, life cycle assessment, and social sciences may be fused to establish a practical biofuel technology." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|