| Posted: Mar 27, 2014 | |

Novel water treatment technology surfaces at Ingenuity Lab |

|

| (Nanowerk Spotlight) Concern about the depletion of global water resources has grown rapidly in the past decade due to our increasing global population and growing demand for other diverse applications. Since only 2.5% of the Earth's water is fresh, it has been reported that almost half of the world’s population is at risk of a water crisis by the year 2025 [1]. Accordingly, significant research efforts have been focused on the desalination of brackish/seawater and the remediation and reuse of wastewater to meet the agricultural, industrial, and domestic water demands. While much progress has been made, the advent of membrane desalination techniques over fifty years ago has given significant impetus to the advancement of water purification technology. However, the need for improved membrane performance and lower operating costs have been a barrier for both researchers and consumers alike. | |

| Current water treatment technology | |

| Water purification membranes are typically divided into four categories according to pore size: | |

|

|

|

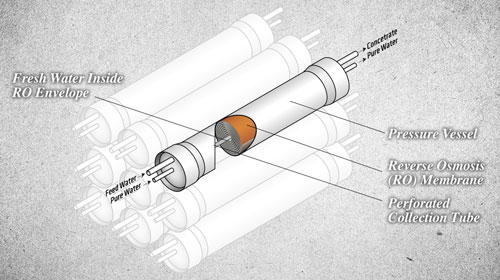

| Feed water quality is an important consideration when selecting a suitable membrane. NF and RO membranes have typically been designed for use of brackish water (2-5 g/L of salt), seawater (35 g/L of salt), and waste water (from agriculture and industry) treatments due to their separation capacity of ions (mono-/di-valent) and organic materials (macromolecules, proteins, glucose, and amino acids) from the water. Of the various candidate materials, conventional desalination membranes are mainly fabricated using aromatic polyamide (PA) thin film composites on a polysulfone support and Loeb-Sourirajan-type cellulose acetate (CA) membranes to create desired architecture. CA membranes exhibit a specific water flux of 1-20 L/m2/day/bar with an average NaCl rejection of > 98%. The advantage of CA membranes is that they are easy-to-make, fairly well priced, and offer excellent stability against mechanical stress and chlorine. However, an inherent weakness of CA membranes is their performance decrease due to changes in pH, temperature, hydrolysis, and fouling. | |

|

|

| (click image to enlarge) | |

| PA membranes on the other hand exhibit a high flux (20-200 L/m2/day/bar) with a high salt rejection (> 99%) as well as increased stability against a wide range of pH and temperature. Unfortunately, despite having benefits, the extremely low resistance to chlorine and membrane fouling are construed as major obstacles for PA membranes. As a result, PA membranes are rendered uneconomical because of the high cost of pre-treatment steps prior to desalination membranes. | |

| Most current desalination technologies on the market are based on energy-intensive processes such as multi-stage flash distillation (MSF; 35 kWh/m3) or a pressure-driven RO membranes (> 3 kWh/m3 for seawater and < 1 kWh/m3 for brackish water). While membrane-based technology is more cost-effective than heat-based technology, the high cost for installation, operation, and maintenance are still major constraining factors for general use of membrane technologies in water treatment. These costs (> 0.5 $/m3 for seawater and 0.2-0.3 $/m3 for brackish water [2]) are higher than the costs of obtaining fresh water from other sources. Furthermore, it has been predicted that current membrane technology is approaching the maximum performance achievable from CA and PA-based materials [3]. Considering that water treatment costs are directly related to the membrane performance, there is an increasing demand for innovative solutions that move beyond the modification of conventional materials, in order to meet scientific and economic requirements. | |

| Aquaporin-embedded biomimetic membrane | |

| At Ingenuity Lab in Edmonton, Alberta, Dr. Carlo Montemagno and a team of world-class researchers have been investigating plausible solutions to existing water purification challenges. They are building on Dr. Montemagno’s earlier patented discoveries by using a naturally-existing water channel protein as the functional unit in water purification membranes [4]. | |

|

|

| (click image to enlarge) | |

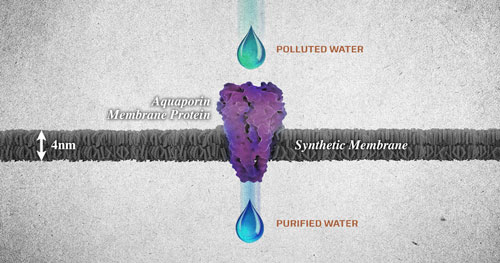

| Aquaporins are water-transport proteins that play an important osmoregulation role in living organisms [5]. These proteins boast exceptionally high water permeability (~ 1010 water molecules/s), high selectivity for pure water molecules, and a low energy cost, which make aquaporin-embedded membrane well suited as an alternative to conventional RO membranes. | |

| Unlike synthetic polymeric membranes, which are driven by the high pressure-induced diffusion of water through size selective pores, this technology utilizes the biological osmosis mechanism to control the flow of water in cellular systems at low energy. In nature, the direction of osmotic water flow is determined by the osmotic pressure difference between compartments, i.e. water flows toward higher osmotic pressure compartment (salty solution or contaminated water). This direction can however be reversed by applying a pressure to the salty solution (i.e., RO). | |

| The principle of RO is based on the semipermeable characteristics of the separating membrane, which allows the transport of only water molecules depending on the direction of osmotic gradient. Therefore, as envisioned in the recent publication ("Recent Progress in Advanced Nanobiological Materials for Energy and Environmental Applications"), the core of Ingenuity Lab’s approach is to control the direction of water flow through aquaporin channels with a minimum level of pressure and to use aquaporin-embedded biomimetic membranes as an alternative to conventional RO membranes. | |

| Ingenuity Lab’s ongoing research efforts | |

| Although introduced a decade ago, only recently has the proof-of-concept for aquaporin-based water purification membranes been demonstrated. Their ultimate success depends on improved membrane performance and membrane functionality which is affected by 1) activity of aquaporin in the membrane (rate of water transport), 2) design concept of the protein-incorporated membrane matrix and 3) membrane manufacturability. | |

| Since aquaporin-incorporated membranes are the key component to attaining higher levels of salt rejection and water flux, Ingenuity Lab has two intense research efforts underway. The first is to improve the quality and properties of the materials used to produce aquaporin-based membranes. Both the production yield and the stability of the aquaporin is being improved through genetic modification. Additionally, new materials are being developed for use as the matrix to house the aquaporin molecules and form stable, biocompatible membranes that provide structural support for the protein and eliminate leakage around the protein. Efficient production of functional aquaporin and biomimetic materials with optimal protein compatibility guarantees the highest level of water purification capacity, which adds maximum economic benefits to the invention. | |

| Ingenuity Lab’s second major research effort focuses on the development of new methods for assembling and fabricating water purification membranes using novel design concepts. The goal of this task is to develop a platform which protects aquaporin from mechanical and chemical stresses, while maintaining functionality, enabling low cost, scalable production. | |

| The work being done at Ingenuity Lab holds great promise for our generation and those to come. Ingenuity Lab’s water purification membranes will be applied to treat wastewater and seawater at a much lower pressure than current membranes. The low-energy requirement and high water flow rate of aquaporins are essential components to the realization of cost-effective water purification membranes. In addition to enhanced energy efficiency, unconventional manufacturability-driven membrane design contributes to cost-competitiveness, setting the membranes apart from traditional, more expensive, desalination processes. In a unique approach, Ingenuity Lab is applying technology and expertise from a variety of disciplines to actively solve some of the world’s most pressing environmental challenges; including here in Alberta, where this technology could be used to reduce the environmental impact of withdrawing bitumen from the oil sands. By reducing the environmental impact of oil sands mining it will allow us to continue to utilize this valuable resource for years to come. | |

| References | |

| [1] Kulshreshtha, S. N. A global outlook for water resources to the year 2025. Water Resour. Manag. 1998, 12(3), 167-184. | |

| [2] Fritzmann, C.; Löwenberg, J.; Wintgens, T.; Melin T. State-of-the-art of reverse osmosis desalination. Desalination. 2007, 216, 1-76. | |

| [3] Elimelech, M.; Phillip, W.A. The future of seawater desalination: energy, technology, and the environment. Science. 2011, 333(6043), 712-717. | |

| [4] Montemagno, C.D.; Schmidt, J.J.; Tozzi, S.P. Biomimetic Membranes. U.S. Patent 7,208,089 B2, 24 April 2007. | |

| [5] Borgnia, M.; Nielsen, S.; Engel, A.; Agre, P. Cellular and molecular biology of the aquaporin water channels. Annu. Rev. Biochem. 1999, 68, 425–458. | |

|

Source: Ingenuity Lab

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|