| Posted: Oct 28, 2014 | |

A nanorobotics platform for nanomanufacturing |

|

| (Nanowerk Spotlight) The rapid miniaturization of devices and machines has fuelled the evolution of advanced fabrication techniques. However, the complexity and high cost of the state-of-the-art high-resolution lithographic systems are prompting unconventional routes for nanoscale manufacturing. | |

| Inspired by natural nanomachines, synthetic nanorobots have recently demonstrated remarkable performance and functionality. Nanoengineers at the University of California San Diego, now have invented a new nano-patterning approach, named Nanomotor Lithography, which translates the autonomous movement trajectories of nanomotors, or nanorobots, into controlled surface features that brings a twist to conventional static optical fabrication systems. | |

|

|

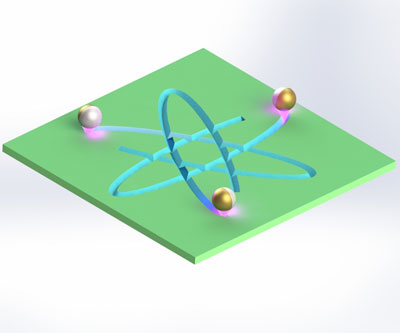

| Schematic of nanomotor lithography by using a Janus sphere motor as a self-propelled nanolens. (Image: Jinxing Li, UC San Diego) | |

| Reporting their findings in a recent online edition of Nature Communications("Nanomotor lithography"), the team, led by Professor Joe Wang, Chair of Nanoengineering, introduced a simple and efficient nanomotor-based nano-patterning technique based on self-propelled nanomasks and nanolenses that brings a twist to conventional static optical fabrication systems. | |

| "Our nanomotor-fabrication strategy combines controlled movement of nanorobots with unique light focusing or blocking abilities for direct surface writing and provides researchers with considerable freedom for creating diverse features with different shapes and sizes," Wang tells Nanowerk. "It allows us to generate spatially defined surface patterns, corresponding to the predetermined path of the nanorobots. We expect that directional propulsion and variation of nanorobot design can be used to generate more elaborate functional features." | |

| For example, the shape and the number of the assembled patches of the nanomotors can be customized to further increase the pattern complexity. Higher order nanorobot organization and modular motor design should lead to further improvements in pattern intricacy. | |

| Diverse pattern morphologies can thus be achieved by rationally designing each component in the nanorobot assembly. | |

|

|

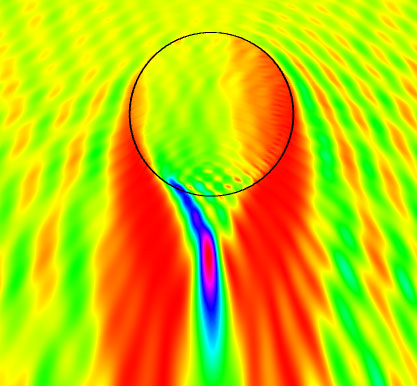

| Finite-difference time-domain (FDTD) model of the intensity of light passing through a 2.16 µm-diameter Janus motor. The black circle represents the contour of the polystyrene sphere and the right hemisphere is coated with a 10 nm Pt film. (Image: Jinxing Li, UC San Diego) | |

| In this technique, the two types of nanomotors – self-propelled platinum nanowires as nanomasks and Janus spheres as near-field nanolenses – 'swim' in water over photoresist surfaces. The nanowires replace the traditional photomask while the Janus spherical motors concentrate the processing light and harness near-field optical effects for direct writing. | |

| "Once light reaches the moving nanomotors, they can effectively perform near-field lithography: the opaque metallic nanowire motors allow for the nanoscale blocking of light while the transparent Janus sphere motors allow for efficient near-field concentration of light," explains Wang. "Due to the small dimension of the nanowire motors and the near-field focusing effect of the Janus sphere motors, sub-wavelength resolution can be achieved." | |

| The team points out that the self-propelled motion along with magnetically guided control makes the new nanomotor approach simple, cost-effective and obviates the requirements of elaborate control systems used in common surface patterning techniques. | |

|

|

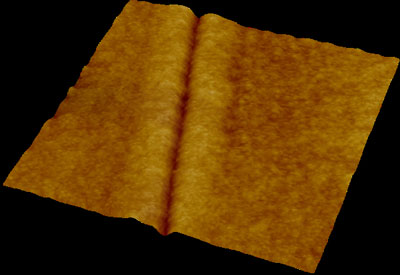

| AFM topographical 3D pattern of a trench line feature created by a 2.16 µm-diameter Janus sphere motor swimming in a 5% H2O2 solution. Both 3D perspective image is shown with displayed area of 6 ? 6 µm2. (Image: Jinxing Li, UC San Diego) | |

| As proof-of-concept, in their Nature Communications paper the researchers demonstrated that such nanorobots can effectively manipulate the processing light beams for optical-based nanopatterning. | |

| By combining advanced nanorobot designs with diverse functionalities we can realize future research and development of the nanorobot patterning method," says Wang. "For example, it could be possible to use thermal, mechanical, electrical, plasmonic, and chemical effects for this kind of dynamic nanorobot lithographic techniques by incorporating specific physical functionality or surface chemistry into the nanorobot." | |

| He concludes that the current capabilities and future possibilities offered by motile optically active nanorobots will lead to the new 'on-the-fly' nanomanufacturing platform and create new opportunities for surface science. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|