| Posted: Dec 09, 2014 | |

Thermotherapy for pain management with a smart thermal patch |

|

| (Nanowerk Spotlight) Advanced health monitoring systems and healthcare devices will become an integral part of the 'Internet of Things'. As a harbinger of things to come, nanotechnology researchers have now demonstrated a smart thermal patch which can be used for thermotherapy for pain management in a user interactive way. | |

| "We were inspired by the fact that in the USA alone, 70 million people suffer from arthritis – among them 3 million children," Muhammad Mustafa Hussain, an Associate Professor of Electrical Engineering at King Abdullah University of Science and Technology (KAUST), tells Nanowerk. "Every day, we experience discomfort due to pain, strain, sprain, and such. Typically, we use chemical based off-the-shelf thermal patches which comes in various sizes based on pain locations and affected area." | |

| These chemical patches have a limited temperature range, last for a maximum of eight hours, and most of them are non-reusable. Therefore, the overall cost of using such patches is not ultimately modest. | |

| An alternative treatment option is laser heating; but this application draws significant amount of power and often cannot be used in locations that are curvilinear and smaller and/or angular in shape. | |

| To address these issues, Hussain and his team have used CMOS technology to devise a silicon based smart thermal patch which is flexible and stretchable. | |

| In the recent past, the KAUST scientists have demonstrated world record 1000% stretching in mono-crystalline silicon (see: "Ultra-stretchable silicon for flexible electronics"). | |

| Now they report a record breaking 800% stretching from copper metallic interconnects. | |

| The researchers have reported their findings in the December 3, 2014 online edition of Advanced Healthcare Materials ("Ultrastretchable and Flexible Copper Interconnect-Based Smart Patch for Adaptive Thermotherapy"). | |

|

|

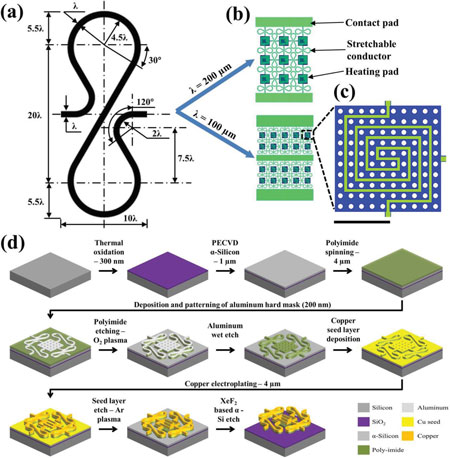

| a) Design of the stretchable lateral spring provides up to 800% uniaxial stretchability. b) The design can be scaled using the scaling parameter λ to obtain devices of different dimensions. In this work, we have fabricated and characterized devices with λ = 100 µm and λ = 200 µm. The heating pads are squares of size 20λ. Contact pads are 2 × 20 mm2 in both cases. c) The copper lines (green) on the heating pads are placed so as to maximize the length and hence the resistance, of the conductor. The PI pad has holes of 100 µm diameter, separated by 200 µm (center-to-center) to reduce the time required for XeF2 gas phase release. Scale bar is 1 mm. d) Process flow followed for the fabrication of the thermal patch. Presence of holes (trenches) in the structure allows air flow. (Reprinted with permission by Wiley-VCH Verlag) (click on image to enlarge) | |

| "Compared to prior demonstrations on stretchable electronics using mostly polymer or composite-based material systems involving 1D nanowires or 2D graphene for stretchable interconnects, electrodes, integrated circuits, light-emitting diodes, supercapacitors, artificial skins, our design significantly increases the stretchability of the heater by using careful engineering design features to absorb the deformation strain in copper thin films with no impact on their low resistance," explains Hussain. | |

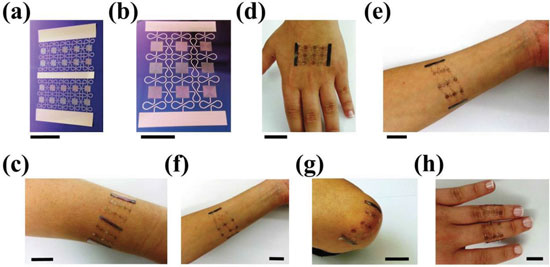

| He notes that, based on the pain location and spatial requirements, the team's device can be stretched and contracted back to its original form. Metallic nature of film allows it to be used for longer lifetime and in reusable manner. | |

| The integration of a battery and communication technology such as Bluetooth makes it a completely mobile-integrated, low-cost, smart electronic system, with precise temperature control using smartphones or mobile gadgets. | |

| For instance, a user can set the temperature and can fall asleep. During that time, the patch not only provides heat but also measures the temperature of the inflamed area and calibrates the temperature as needed. A user can also set a timer to turn it off when needed. Usage data can be monitored remotely by a healthcare professional or doctor. | |

| According to the researchers, the overall cost of the gadget is less than $4. | |

|

|

| a,b) Optical images of the thermal patches after release for λ = 100 µm and λ = 200 µm, respectively. c) The application of thermal patch (λ = 100 µm) on human skin, with 200% lateral strain. d–f) Thermal patch (λ = 200 µm) applied on the human skin with no strain (d), 150% uniaxial strain (e), and 150% lateral and transverse strain (f). g) Thermal patch conformally bent around an elbow joint (bending radius 6.3 cm). h) Thermal patch wrapped around two fingers (bending radius 0.96 cm). All scale bars are 2 cm. (Reprinted with permission by Wiley-VCH Verlag) | |

| One critical fundamental scientific achievement to realize this work was to achieve stretching ability in a metal. | |

| "Metal has a higher heating capacity compared to the traditionally used flexible and stretchable materials such as polymer, fiber, and paper," says Hussain. "However, except recent innovation of stretchable liquid metal (eutectic gallium indium) which also injected inside a polymeric hollow fiber, there is no report which describes a metal which can be stretched more than 350%. Therefore, using a horse shoe design – which in itself is not new – and with rigorous structural modeling, we have developed a set of governing empirical relationships between stretching and area efficiency which allows us to absorb the deformation strain making the metals ultra-stretchable." | |

| Hussain and his team used copper – which is used in state-of-the-art CMOS technology for metal interconnects and is fully CMOS process compatible. To deal with the inherent rigidity of copper, the team has introduced stretchability using a lateral spring design, achieving a record breaking 800% stretching from copper metallic interconnects. | |

| The device has copper based island like thermal heaters and sensors with a communication and controller IC and a coin sized battery. | |

| "This work with unprecedented stretchability in naturally rigid copper interconnects opens up exciting opportunities in the emerging field of flexible and stretchable electronics and lays down the foundation of smart, web-integrated electronic systems with life in them," concludes Hussain. | |

| This work was presented as one of the finalists in Falling Walls competition held in Berlin last month. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|