| Posted: Jun 18, 2015 | |

Novel nanosphere lithography to fabricate tunable plasmonic metasurfaces |

|

| (Nanowerk Spotlight) In conventional nanosphere lithography (NSL), the nanosphere mono- or bilayers, which serve as the lithographic masks, can be fabricated by spin-coating, convective self-assembly or drop casting. Ultimately, the nanosphere configurations in the layers are determined by the spontaneous self-assembly process during these techniques. Therefore, the final configurations are limited to those with or close to the minimal free energy giving rise to very simple patterns. The metal nanostructures fabricated from these masks thus possess simple geometries as well. | |

| In new work, an international research team from Japan and the U.S. managed to circumvent this thermodynamical restriction by putting the monolayers in a confined environment and constructing the bilayers with sequential stacking, both of which are critical for the formation of the moire patterns. | |

| The team reported their findings in the May 28, 2015 online edition of ACS Nano ("Moiré Nanosphere Lithography"). | |

| "In this work, for the first time, we were able to construct a variety of moire patterns from polystyrene nanosphere monolayers and subsequently employed the etched moire patterns as masks to fabricate various novel metasurfaces," Kai Chen, a postdoctoral researcher at the National Institute for Materials Science (NIMS) in Japan, and the paper's first author, tells Nanowerk. "These moiré patterns are inaccessible by conventional nanosphere self-assembly techniques due to the thermodynamical instability. We were able to overcome this restriction and fabricated bilayer moire patterns in a layer-by-layer fashion. The metasurfaces fabricated by moire nanosphere lithography (M-NSL) exhibited a number of complex nanostructures providing new capabilities to engineer light-matter interactions." | |

|

|

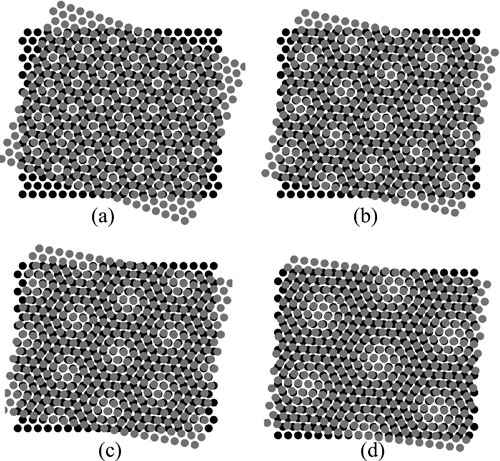

| Illustration of relative rotation of (a) 19°, (b) 12°, (c) 9°, and (d) 7.5° between the bottom (black) and top (gray) monolayers of spheres, leading to the formation of various moiré patterns. (Reprinted with permission by American Chemical Society) | |

| NSL is a scalable and versatile nanofabrication technique and has been widely used to fabricate metallic nanoparticles as well as dielectric nanostructures. M-NSL greatly extends its capabilities to fabricate complex nanostructures with tailored optical properties. | |

| Chen recounts how he was looking for methods to construct nanosphere bilayers as lithographic masks as in conventional NSL when he noticed some very peculiar patterns on his first sample. Then he repeated this procedure and found the fascinating moiré patterns on a large scale. | |

| "With sequential stacking or layer-by-layer technique, the top layer is separated from the bottom layer and it can move freely relative to the bottom layer," explains Chen. "With the confined environment, we significantly limited the degree of freedom of the nanospheres in the monolayers and thus some metastable configurations became stable and retained their structures. The combination of these two allows for the relative rotation of the domains in the top and bottom layers giving rise to the moire patterns." | |

| This novel technique considerably extends the capability of NSL with its yield of elaborate patterns, which will provide a low-cost, high-throughput approach towards complex nanofabrication masks and novel metasurfaces, which can be used to manipulate light-matter interactions and enhance the sensitivity of molecular sensing. | |

| Conventional NSL can only produce nanoparticles with simple shapes, such as triangles from monolayer and dots from bilayers. Combined with etching or angled deposition techniques, other irregular shapes, such as crescents or rings, can also be fabricated. However, the shape variations are still very limited and usually the nanoparticles on one substrate exhibit the same shape. Conventionally, more complex nanostructures with unique properties require e-beam lithography or focus ion beam lithography that is time-consuming and high-cost. | |

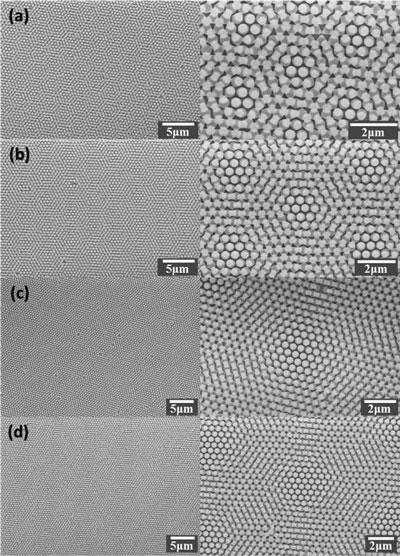

| Yuebing Zheng, Assistant Professor of Mechanical Engineering and Materials Science & Engineering at the University of Texas at Austin, who is leading the U.S. research team, points out that in M-NSL, a number of nanoparticles with exotic shapes can be fabricated on a single substrate. The arrays of these nanoparticles – or metasurfaces – show tunable broad surface plasmon resonances, which significantly extends the fabrication capabilities of conventional NSL. "It is expected that these metasurfaces can be employed for surface-enhanced spectroscopic studies of molecules and biological cells," he says. | |

| "In addition, broadband resonances are also desirable for light-harvesting applications where these metasurfaces can enhance the absorption of sunlight," as pointed out by Tadaaki Nagao, group leader of Nano-system Photonics at NIMS. | |

| Furthermore, several tunable parameters in M-NSL – such as nanosphere size, etching time and deposition conditions – allow for further engineering the shapes of the nanoparticles. | |

|

|

| SEM images of a series of gradually changing patterns: the unit is growing bigger from top to bottom. The left column gives a broad overview for each pattern, and the right column gives a zoom-in view of each “repeating” unit. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| The team expects that M-NSL will considerably improve the nanofabrication capabilities for novel metasurfaces and provide excellent platforms to engineer light-matter interactions on the nanoscale. | |

| They are currently studying the metasurfaces fabricated by M-NSL. By comparing the experimental results with numerical simulation, they will be able to understand the different plasmon modes in the metasurfaces. | |

| "We are also working on characterizing M-NSL by tuning the parameters in this technique, such as the size of the nanosphere, the etching time, and the metal deposition conditions," says Chen. "We anticipate that the tuning of these parameters will give rise to different moiré patterns and hence metasurfaces enriching the family of nanostructures by M-NSL." | |

| This means that in future, complex nanostructures can be rationally designed and then fabricated by M-NSL or other types of extensions of NSL. Complex nanopatterns and the complementary metasurface can then be engineered over large areas. | |

| Chen cautions that, in order to achieve those goals, two sets of challenges do exist: "1)Currently the nanosphere domain size is not controllable and relatively small. It is always desirable to have the ability to produce large-area single-domain monolayers. 2) As for M-NSL, it is desirable to be able to control the rotation angles between the domains in top and bottom layers. Then we can rationally design and fabricate the moire patterns and the complementary metasurfaces." | |

| Other researchers working on this project include Bharath Bangalore Rajeeva, graduate student, Zilong Wu, graduate student, Michael Rukavina, undergraduate student, all at the University of Texas at Austin and Thang Duy Dao, Satoshi Ishii, Masakazu Aono from NIMS, Japan. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|