| Posted: Mar 21, 2017 | |

Transforming greenhouse gas CO2 into carbon nanotubes |

|

| (Nanowerk Spotlight) The cement industry is one of the largest sources worldwide of carbon emissions, accounting for around five per cent of global emissions. Two thirds of these CO2 emissions are released during the chemical process of burning limestone for cement production and can only be cut by extracting the CO2 from the emissions in one form or another. | |

| In a previous Nanowerk Spotlight we looked at how nanoengineering of cement-based materials can result in outstanding or smart properties ("Nanotechnology in the cement industry – a patent analysis"). | |

| Now, in two new studies, researchers show that cement plants can have their carbon dioxide exhaust eliminated while co-producing carbon nanotubes. | |

|

|

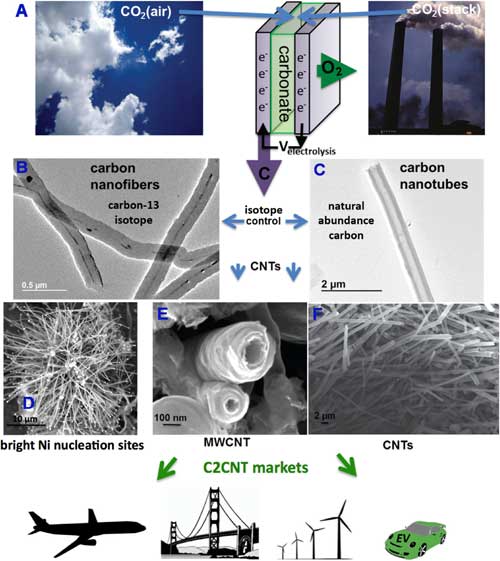

| Scheme for the electrolytic synthesis of carbon nanostructures from carbon dioxide: (a) the source of CO2 can be either smoke stack concentrations of CO2 or air (without requiring pre-concentration) dissolved in molten carbonate, (b) and (c) isotope controls formation of carbon nanotubes or nanofibers, the more valued CNTs are made from the less expensive natural abundance CO2. High oxide concentration produce tangled morphologies (d) while low oxide produces straight nanotubes (f). (e) Bright nickel nucleation sites, as identified by EDS, initiate CNT growth. Lower panel: The CNTs and carbon nanofibers provide high conductivity and superior carbon composite lightweight structural materials for jets, bridges, wind turbines, and electric vehicle bodies and batteries. (© Elsevier) (click on image to enlarge) | |

| "We have demonstrated that with our C2CNT (carbon dioxide into carbon nanotubes) process, a wide portfolio of tailored carbon nanotubes (CNTs), such as those with special shapes or conductivity can be made," Stuart Licht, a professor of chemistry at George Washington University, tells Nanowerk. | |

| In the first paper, in Journal of CO2 Utilization ("Transformation of the greenhouse gas CO2 by molten electrolysis into a wide controlled selection of carbon nanotubes"), Licht and his team present the transformation of CO2 into specific, controlled carbon nanotubes. | |

| This study presents a straightforward process that transforms CO2 to carbon nanotubes by molten electrolysis with inexpensive (nickel and steel) electrodes and low voltage. This synthesis consumes only CO2 and electricity, and is constrained only by the cost of electricity. | |

| "Control of electrolysis parameters opens up a wide portfolio of CNT morphologies including hollow or solid, thick or thin walled," says Licht. "Our portfolio also includes doped CNT. Molten carbonate electrosynthesized boron doped CNTs have high electrical conductivity. The CNT from CO2 synthesis remains single step (one pot) in which a specific impurity is dissolved in the electrolyte to achieve a desired doped CNT characteristic." | |

| The C2CNT technology is applicable to the direct removal of atmospheric CO2 or the elimination of industrial CO2 from smokestacks. | |

|

|

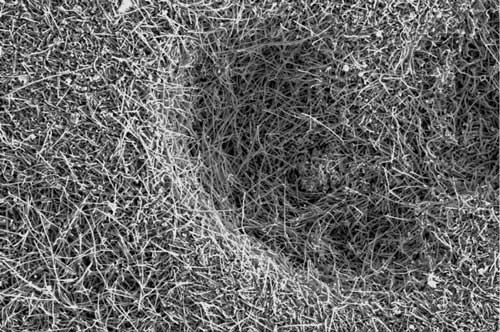

| SEM image of carbon nanotubes produced from CO2 at the cathode during constant current electrolysis in a molten Li2CO3 electrolyte. (Image: Licht Group, University of Washington) (click on image to enlarge) | |

| In the second paper, also in the Journal of CO2 Utilization ("Co-production of cement and carbon nanotubes with a carbon negative footprint"), Licht presents the use of C2CNT to retrofit cement plants. | |

| Cement production today has a massive carbon footprint and simultaneously releases CO2 both from limestone and from fossil fuels, and hence cement plant smokestacks have much higher CO2 content (5 times higher than gas fired electric power plants). | |

| This study compares conventional cement plants to alternative C2CNT cement plants and shows: | |

|

|

|

| Scaling up the C2CNT process to work with commercial plants is the ongoing second stage of the researchers' investigations. As part of this effort they have advanced to the semifinals of the Carbon XPrize as the C2CNT team. The Carbon XPrize is a global competition for research teams to transform CO2 from a power plant into the most valuable product. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|