| Posted: Jun 09, 2009 | |

High yield fabrication of fluorescent nanodiamonds |

|

| (Nanowerk Spotlight) Developed originally for the surface finishing industry, diamond nanoparticles are now finding new and far-reaching applications in modern biomedical science and biotechnologies. Researchers have already demonstrated that nanodiamond particles possess several unique features – including facile surface modification, long-term photostability, and no fluorescence blinking – that makes their detection and long-term tracking in living cells not only possible but practical (read more: Single fluorescent nanodiamonds as cellular biomarkers). Two of the biggest advantages of using nanodiamonds in biomedical applications is that they are not toxic and their fluorescence related to color centers is absolutely stable. | |

| The importance of novel markers for microcopy cannot be underestimated. Such markers can provide novel information about functioning of protein in cell. Owing to their unlimited photostability diamond nanoparticles can be used for long-term monitoring of intracellular processes. Diamond nanoparticles also appear to be ideal candidates for ultra microscopy techniques like STED (see: STED microscopy reveals crystal colour centres with nanometric resolution). | |

| Furthermore, nitrogen-vacancy color centers in diamond have non-zero spin in the ground state. This allows their use as markers for magnetic resonance imaging with very high sensitivity (see: Nanoscale imaging magnetometry with diamond spins under ambient conditions). | |

| To date, few methods exist to produce diamond nanoparticles containing color centers (c-diamond), but they are only laboratory-scale. The most common, large-scale nanodiamond production method, detonation, produces diamond nanoparticles which do not contain any color centers but impurities such as surface-or lattice-aggregated nitrogen and metals in significant amounts. | |

| A German-French research team has now developed a high yield method for the large-scale production of fluorescent nanodiamonds. They have reported their findings in a recent edition of Nanotechnology (High yield fabrication of fluorescent nanodiamonds). | |

| Their technique allows for the fabrication of isolated ultrasmall quasi-spherical diamond nanoparticles with dimensions less than or equal to 10 nm. These nanodiamonds present the following features: they are made of c-diamond nanocrystals with controlled size, shape and composition, a very high crystallinity and little impurity but selected doping heteroatoms such as isolated substitutional nitrogen. | |

| Potential applications of nanodiamonds for biology depend critically on our ability to attach diamond nanoparticles to proteins. Therefore it is of crucial importance to show that important functional groups like biotin can be reliably linked to the surface of diamond nanocrystals. | |

|

|

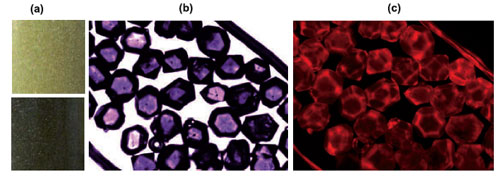

| Optical observation of the raw 80–100 mesh HPHT diamond. (a) HPHT microdiamond seen with the naked eye: initial (above) and after electron irradiation (below). (b) Bright-field transmission image of the microdiamond after electron irradiation and annealing. (c) Image of the microdiamond after electron irradiation and annealing recorded with a fluorescence microscope under green excitation (20 ms duration). (Reprinted with permission from IOP Publishing) | |

| "Our starting material is a highly crystalline high pressure, high temperature (HPHT) micron-sized diamond and our method is based on milling these bigger diamonds," Fedor Jelezko, a researcher at the 3rd Physical Institute at the University of Stuttgart, tells Nanowerk. "We have achieved a production yield of 15% (w/w) of the initial microdiamond converted into ≤ 10nm nanodiamonds for a 24 hour milling time. This yield is several orders of magnitude higher than the ones for current production methods of c-diamonds." | |

| In this work, Jelezko and his University of Stuttgart colleagues worked wit scientists from the Université d’Evry-Val d’Essonne and the Nanomaterials Research Group at CNRS in Belfort, both in France, also show that very small nanocrystal (smaller than 10 nanometers) show stable and bright luminescence. | |

| The production process for these c-diamonds contains five steps: First, nitrogen-vacancy creation is obtained by 10 MeV electron irradiation of raw HPHT microdiamond followed by annealing at 800 °C under vacuum. Then, milling of the fluorescent microdiamond is performed in two steps, micronization and nanomilling. Third, purification includes a hot HF/HNO3 treatment followed by a series of centrifugation steps. After completion of the acid treatment, an excess of Milli-Q ultrapure water was added to the sample which was then mechanically dispersed before centrifugation. The diamond sample precipitates under these acid conditions, which allows easy recovery from the acid. Supernatants obtained by three subsequent centrifugations are pooled and desalted by ultrafiltration. | |

| "The observations we made in our work will be useful to adjust at will nanodiamond properties with minimal loss in crystallinity for any of these specific applications and needs – particle size, shape, composition: nitrogen-vacancy content, nanoparticle doping with selected heteroelements, surface functionalization," says Jelezko. "The industrial scale production of ultrasmall nanodiamonds represents a breakthrough toward these objectives." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|